Grundfos develops smart solutions for India's auto industry

Pump supplier to the automotive industry develops innovative products aimed at furthering efficiency gains and reduced costs across manufacturing operations.

Grundfos India, a leading pump supplier to the automotive industry, is developing advanced pumping solutions exclusively for the automotive industry. These are aimed at driving improved efficiency gains for manufacturing operations from the machining area till the assembly line.

Today, each and every automobile manufacturer and as well as leading component manufacturers are looking for ways to improve efficiency levels at their plant, cut production costs and of course reduce their carbon footprint in the manufacturing process.

Grundfos’ current product portfolio includes a wide range of innovative pump solutions claimed to enhance the energy efficiency drive in manufacturing plants. The company says its advanced e-solutions programme can help optimise processes and reduce energy consumption up to 50 percent in some applications.

The broad range of pumps caters to varied applications including water supply, pressure boosting, waste water, water treatment and disinfection system, firefighting, boiler feed, cooling and heating, energy audit, machine tools, filtration, part washer, chiller, process water, surface cleaning and painting. Efficiency gains in each of these processes can add up to substantial overall gains and over a period of time deliver handsome cost savings too.

Grundfos primarily caters to three segments – building services, water treatment plants and industry. The automotive sector, classified under the industry segment, is a key revenue provider to the company which currently has a 60 percent market share in the Indian auto and ancillary segments.

Efficient operations

Talking about the company’s products and solutions aimed at delivering efficient operation, Shankar Rajaram, head – industry, North and South, Grundfos India, says, “There is a significant increase in costs due to energy intake in the area of vehicle products every year. Our expert solutions and products are accurate, reliable and energy efficient which can assist automobile companies to drive in a greener future. Grundfos is a global leader in machining and has a near-65 percent market share.”

Among Grundfos’ USPs is its ability for custom-designed solutions and its comprehensive range of products that cater to a plethora of industrial requirements. Carmakers like Tata Motors and Renault Nissan have employed the technologically advanced Grundfos pumps at their manufacturing plants.

Typically, in an automobile manufacturing plant which has a capacity of a million units, around 3,500 pumps are required for various applications such as cooling towers, pressure boosters, water treatment, presses booster, heat exchangers, welding lines and chiller pressure. Both automakers and component suppliers, along with their contractors, use these products for a host of applications. Increased focus is now on pre-treatment and painting applications and as much as 30 percent of the total number of pumps is employed in the paint shop.

Besides OEMs, component makers also use these pumps for making actuators, cylinder valves, cylinder blocks, exhaust manifolds and transmission gears. According to Grundfos officials, the auto industry, which is heavily dependent on machine tool manufacturers, finds Grundfos pumps as reliable equipment for turning, milling, drilling and cutting operations.

The company caters to most leading OEMs in India including Honda Cars India, Maruti Suzuki India, Hyundai Motors India, Renault-Nissan India, Mahindra & Mahindra, Ashok Leyland, General Motors India, Mercedes-Benz India, Volvo Buses India, Tata Motors, Volkswagen India and Ford India. Key supplier clientele includes Bosch, Delphi, Samvardhana Motherson Group, Mazak, Makino and all leading tyre makers such as MRF, JK Tyres, Michelin, Bridgestone, Apollo and TVS Tyres.

Extensive product portfolio

Grundfos has over 15 products in its range including the CM Pump which is compact in design and can be used to make multiple configurations. The CR pump range, which is an elementary pump, is utilised in almost any industrial solution with benefits of energy efficiency and higher performance. NB/NK pumps are designed and built for industrial applications and come with a variety of carefully considered technical features; the key advantages are said to be unhindered liquid flow, no leakage and better corrosion resistance.

SE pumps are technically advanced pumps with efficient single-channel or Vortex impellers which reduces the likelihood of clogging, offering maximum up-time and low operational costs. SEG pumps are developed to ensure there is no closing and minimised downtime costs by maintaining performance.

MTH, MTS and MTR range pumps are vertical, single multi-stage centrifugal pumps created for pumping of cooling lubricants for machine tools and similar applications. While machine tool pumps are immersible pumps based on a combination of superior material and aimed at delivering optimum efficiency, reliability and ease of service, MTB pumps are specially designed to transport fluids which have machining chips and abrasive particles.

If the requirement is for additional pressure, then the hydro booster pumps are said to handle the most difficult jobs with ease and accuracy. These pumps are highly efficient and service-friendly too.

In 2015, Grundfos India recorded a turnover of Rs 384 crore, with around 4 percent of the total business coming from exports to countries like Bhutan, Bangladesh and the Maldives. Around 12 percent of its total revenues are from the automotive industry.

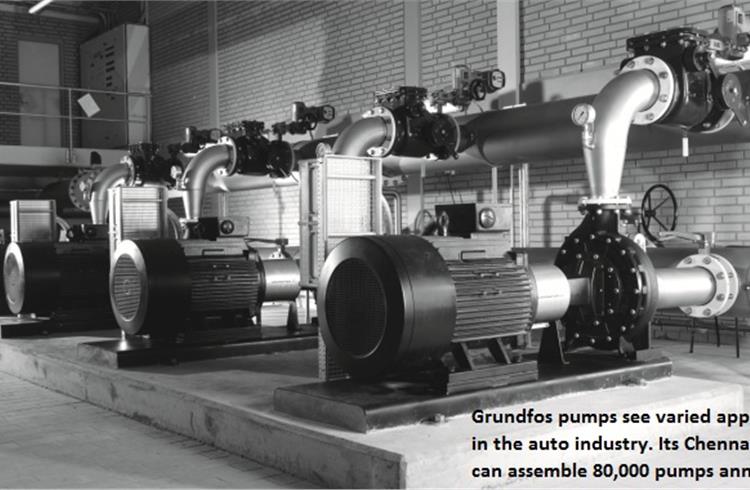

The company, which is looking to increase localisation levels, has an annual assembling capacity of 80,000 pumps with overall localisation of 25-30 percent. It currently sources components from its facilities from group companies located in Denmark, Singapore, Taiwan, Hungary and China.

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Kiran Bajad

By Kiran Bajad

26 Apr 2016

26 Apr 2016

8023 Views

8023 Views