VC-Turbo: the world's first production-ready variable compression ratio engine

Smart power and greater control from one of the most advanced internal combustion engines ever created.

The automobile engineering world has seen a recent breakthrough. Infiniti’s VC-Turbo engine is the world's first production-ready variable compression ratio engine and it makes its production debut on the new QX50.

This unique variable compression technology represents a breakthrough in combustion engine design – the QX50's 2.0-litre VC-Turbo continually transforms, adjusting its compression ratio to optimise power and fuel efficiency. It combines the power of a 2.0-litre turbocharged petrol engine with the torque and efficiency of an advanced four-cylinder diesel engine.

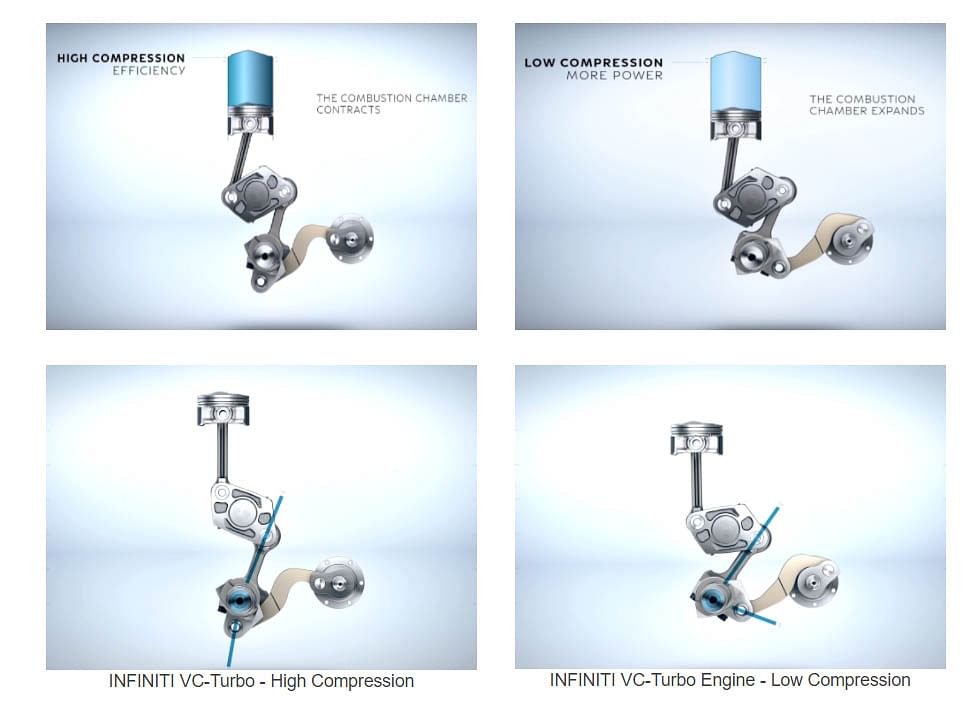

The VC-Turbo changes its compression ratio seamlessly with an advanced multi-link system, continuously raising or lowering the pistons' reach to transform compression ratio – offering both power and efficiency, on demand.

A high compression ratio gives greater efficiency, but in certain applications poses the risk of premature combustion ('knocking'). A low compression ratio allows for greater power and torque, and avoids knocking. In operation, the QX50's VC-Turbo engine offers any compression ratio between 8:1 (for high performance) and 14:1 (for high efficiency). Deploying smart power for greater control, the empowering engine exemplifies Infiniti's driver-centric approach.

The blend of performance and efficiency represents a compelling alternative to diesel, challenging the notion that only hybrid and diesel powertrains are capable of delivering high torque and efficiency. The engine delivers 268hp (200 kW) at 5600rpm and 280 lb ft (380Nm) at 4400rpm. The VC-Turbo's specific power output is higher than many competing turbocharged petrol engines, and comes close to the performance of some V6 petrol engines. The unit's single-scroll turbo ensures immediate accelerator responses, on demand.

Equipped with the VC-Turbo engine, the QX50 is competitively efficient, delivering petrol fuel economy of 27mpg (US combined, front-wheel drive; 26mpg all-wheel drive). In front-wheel drive specification, this offers a 35 percent improvement in fuel efficiency over the V6 petrol engine in the previous QX50, while the new all-wheel drive model's 26 mpg represents a 30 percent improvement.

Other highlights include compact packaging and weight-saving technologies. The engine block and cylinder head are cast in lightweight aluminum alloy, while the transformative multi-link components are manufactured in high-carbon steel alloy. Compared to Infiniti's 3.5-litre VQ V6 engine, the 2.0-liter VC-Turbo weighs 18kg less and requires less space in the engine bay.

The engine employs the world's first multi-link system and an electric motor with a unique Harmonic Drive reduction gear to transform its compression ratio. The electric motor is connected to the Harmonic Drive with a control arm; as the Harmonic Drive rotates, the control shaft at the base of the engine rotates, moving the multi-link system within the engine. As the angle of the multi-link arms changes, it adjusts the top-dead-center position of the pistons – and the compression ratio with them. An eccentric control shaft changes the compression ratio of all the cylinders at the same time. As a result, the engine capacity varies between 1,997 cc (for a low 8:1 ratio) and 1,970 cc (high 14:1 ratio).

The VC-Turbo can switch between both Atkinson and regular combustion cycles without interruption, enabling greater efficiency and performance as it transforms.

Under the Atkinson cycle, air and fuel intakes overlap, allowing the fuel in the combustion chamber to expand to larger volumes for greater efficiency. The Infiniti engine operates the Atkinson cycle under higher compression ratios, with longer piston strokes allowing the intake valves to open for a short time as the compression stroke starts. The Atkinson cycle is commonly used in hybrid engines to maximize efficiency.

As the compression ratio drops, the engine reverts to a regular combustion cycle – intake, compression, combustion, exhaust – in separate phases to enable greater performance.

The VC-Turbo engine combines a number of existing Infiniti technologies to realise its variable nature. The engine employs both MPI (multi-point injection) and GDI (gasoline direct injection) to balance efficiency and power in all conditions:

GDI improves combustion efficiency and performance, and enables the engine to avoid knocking at higher compression ratios

MPI mixes fuel and air earlier, enabling complete combustion in the chamber for greater efficiency at low engine loads

The engine switches between both at regular engine speeds, with both sets of injectors able to work in conjunction under higher loads.

A single-scroll turbocharger maximises performance and efficiency, enabling immediate throttle responses at any speed or compression ratio. The turbocharger ensures equivalent performance to a naturally aspirated six-cylinder unit. Small enough to aid the compact overall dimensions, a single-scroll system also reduces the loss of thermal energy and exhaust pressure.

An integrated exhaust manifold is built into the aluminum cylinder head to further enhance packaging and efficiency. This enables Infiniti engineers to position the catalytic converter next to the turbo, creating a shorter flow path for hot exhaust gases. This means the emissions control process can start sooner, as the catalytic converter heats up more quickly.

Closely controlling the flow of exhaust gases through the turbocharger, an electronically-controlled wastegate actuator maintains turbocharger boost pressure. This ensures high fuel efficiency and performance under all conditions while minimizing emissions.

The uncommonly smooth VC-Turbo does away with the two balance shafts required in conventional four-cylinder engines, due to the layout of its multi-link system.

The VC-Turbo is also smoother than conventional in-line engines, and has the low noise and vibration levels expected of a traditional V6. This is, in part, a result of its multi-link design, where the piston connecting rods are almost vertical during the combustion cycle (rather than moving wider laterally, as they would in a traditional crankshaft rotation). This represents the ideal reciprocating motion, and entirely negates the need for balance shafts. Despite the addition of a multi-link layout, the engine is therefore as compact as a conventional 2.0-liter four-cylinder engine.

The result is uncommonly low levels of vibration. During internal tests, Infiniti says it benchmarked the engine against four-cylinder engines from rival manufacturers. The VC-Turbo produces reduced engine noise – almost as refined as a V6.

A low-friction 'mirror bore coating' contributes to a 44 percent reduction in cylinder friction, allowing the engine to rotate more smoothly. The coating is applied to the cylinder walls by a plasma jet, then hardened and honed to create ultra-smooth cylinder walls.

The QX50's 2.0-litre VC-Turbo engine employs the world's first active engine mount vibration damping system, called an Active Torque Rod (ATR), to reduce engine noise even further. The QX50 is the only car in its class to offer this kind of technology. Integrated into the upper engine mount, where the most high-torque noise and engine vibration is generated, the ATR has a G-sensor that detects vibrations. It then creates opposite, reciprocating vibrations, enabling the four-cylinder engine to be as smooth and quiet as a V6, reducing engine noise by 9dB (compared to the current QX50). This helps to make the VC-Turbo one of the quietest and smoothest engines in the premium SUV segment.

RELATED ARTICLES

Tech Talk: Breakthrough for EVs as new battery tech halves charging times

New immersion cooling battery tech has improved Renault Megane EV’s range and charging times.

Car Launches and Reveals in May 2025

No SUVs this time, but a new MPV, an electric sportscar and two new hatchbacks are in the pipeline.

CVs in FY25: On The Slow Road To Recovery

The commercial vehicle sector witnessed a mixed performance in FY25, led by buses with a 15% growth, and declines in bot...

By Autocar Professional Bureau

By Autocar Professional Bureau

14 Dec 2017

14 Dec 2017

15496 Views

15496 Views

Shahkar Abidi

Shahkar Abidi