iASYS pitches product validation management for India's auto industry

iASYS eyes the need to integrate individual validation competencies into a well-designed structure, which enhances cross-functional and vertical efficiencies in product lifecycle management - product validation management.

Pune-based iASYS Technology Solutions, a provider of R&D solutions ranging from test benches and automation control systems, test data and validation process management, is betting big on the emerging requirement of integrating functionalities for achieving enhanced efficiencies in overall product validation lifecycle management.

The company was set up in 1999 and has been operating in the automotive R&D space since then. Speaking to Autocar Professional, Puran Parekh, CEO, iASYS, says: “Earlier, we were doing only automation software. However, currently we are providing control systems, dynamometers and other lab test equipment. We can set up a complete lab with multiple test beds. So we are growing by adding more products and new competencies. Business-wise, our turnover is around Rs 27-30 crore (FY2014-15). So far, our model has witnessed doubling of revenues in every third year.”

iASYS has coined product validation management (PVM) as a reliable approach that lays down the foundation for model-based engineering approach. While product lifecycle management (PLM) is popular automotive jargon, PVM is relatively new and specific to the nature of integrated solutions this company provides.

What is PVM?

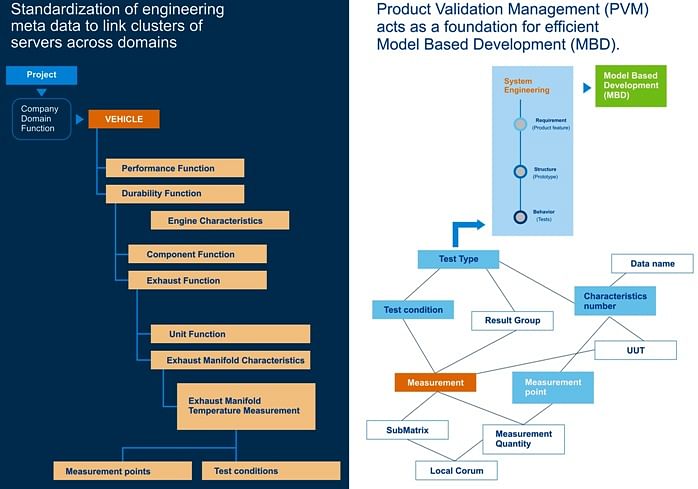

Explaining the concept of PVM, Parekh says, “The product development stages involve simulation, validation and physical testing. While simulation software helps simulate real-world conditions with conventional accuracy, largely cutting down on physical prototyping, physical testing cannot be entirely overlooked. Instead data from actual physical testing should go back to the digital simulation to improve its maturity and accuracies. We have created a platform across the enterprise coming from top validation plan, split into different function groups connecting each of them vertically and horizontally. This integration clearly results in improvements in efficiencies.”

Parekh emphasises what he calls engineering meta data dictionary, which standardises the entire process and its language across the organisation. “If anyone wants to know full load power performance of a vehicle, then everybody understands what that means and knows where the data is stored. The organisation can have cross-functional communication this way. So across different functional departments, they can learn about any given aspect of the engineering data of any vehicle and be on the same page, thanks to the standardised glossary and organised data,” he explains.

For example, an engine development team would design various components and simulate them, followed by actual physical testing. The correlation here is within the engine domain. However, if the task is to correlate the engine’s fuel efficiency with the vehicle performance including vehicle’s fuel economy, then this functionality becomes a cross-domain communication between concerned teams. This example clearly highlights the vertical as well as horizontal integration of separate functionalities.

“So basically we are talking about two levels of efficiency – cross-domain communication efficiency, which is completely not there in the industry currently. Secondly, achieving efficiency within the functional domains, which can be understood by parameters such as reduction in the development time by improving their simulation models. PVM is the whole concept here,” he adds.

iASYS has been working with a major Japanese OEM where the company has set up the complete product validation infrastructure for them, reveals Parekh.

PLM vs PVM?

It is widely known that while earlier the vehicle development period ranged between 4-5 years, the same now takes around three years or less. The basic functions involved in product development, on the other hand, have remained the same.

“So that’s why you see so many recall issues because you simply cannot do enough testing due to shrinking product development cycles. The shrinking development cycles demand rapid improvements in the development process. You have infinite possibilities on the road and you cannot simulate all. This can only be done by bringing the digital simulations closer to the real-world conditions. This will result in improved accuracies and hence avoiding recalls and costs,” argues Parekh.

According to him, iASYS is striving to bring in a process-oriented approach in the complete product lifecycle with emphasis on the validation phase. “PVM signifies a complete product lifecycle. It is not a rival to PLM. It is complementary to PLM,” Parekh hastens to mention.

It is understood that OEMs subscribe to best development and simulation tools depending on their core functionalities from different software vendors. Nevertheless, vehicle makers have to integrate and correlate data across different tools to maximise productivity. “The PVM exactly does that. It integrates all the individual competencies into a common structure,” he highlights.

Growing business for PVM and test equipment

The company has bagged a number of respectable orders including setting up an entire R&D lab with five test benches for a luxury European carmaker. According to Parekh, the R&D lab is running on an iASYS-developed automation system for global regulations. iASYS officials say that they bagged this high-profile contract in the January-March 2016 period.

The company has also won an order from the Automotive Research Association of India (ARAI) for a transient dynamometer for certification and development of BS VI emission norms.

Parekh is particularly bullish about the prospects of the transient dynamometer setup as Indian automakers' readiness to BS VI norms gathers steam. “The entire emission certification process at ARAI is completely managed with our PVM system. Now they have given us the order to expand to Euro 6 norms. We were the first Indian company which made a turnkey test bench setup. We have supplied these systems to Volvo-Eicher, Tata Motors, ARAI and Mahindra R&D among others,” says Parekh.

The upcoming BS VI emission norms are clearly benefiting companies like iASYS and in the run up to April 2020, the demand from automakers for innovative software tools will only surge.

This article was first published in Autocar Professional's October 1, 2016 - Software & Simulation Special - issue.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

By Amit Panday

By Amit Panday

17 Oct 2016

17 Oct 2016

12623 Views

12623 Views

Autocar Professional Bureau

Autocar Professional Bureau