Auto industry looks at innovation to balance cost, safety and vehicle weight

Experts debated how the designers need to be more creative while building vehicles for a highly price-sensitive market like India.

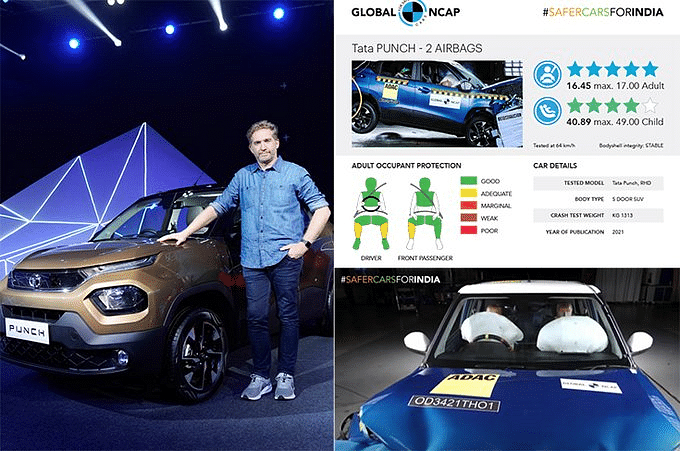

"Safety is an absolute pillar for TataMotors. You cannot design a vehicle that's any less than a 5-star vehicle. We explore lightweighting options – it’s a balancing act meeting various needs with safety," said Martin Uhlarik, Global Design head, Tata Motors.

He was speaking on Day 2 of the virtual conference organised by Autocar Professional on ‘Innovative solutions for lower vehicle weight’ in a panel moderated by Hormazd Sorabjee, editor Autocar India. Santhosh K Jacob, Director and Country Manager, Igus India and Sanjeev Ghosh, Senior Technical Specialist, Autodesk India were also part of the conference.

Uhlarik explained how the designers need to be more creative while building vehicles for a highly price-sensitive market like India. Refuting popular notions about the weight of the vehicle and its safety, Uhlarik pointed out that the "segment & typology of vehicle decides its weight. The body size needs to communicate strength depending on segment. Fine balance between vehicle attributes & lightness. They should not be overburdened with mass. Communicating a nimble aspect is important."

Offering an insight into the working of current trends, he added that currently designers are working from the ground up and from the design point of view, EVs are going to offer a lot of opportunities. "I see the full-electric generation of cars as a very exciting one for designers.” Tata Motors has had a strong showing in Global NCAP’s crash test results in recent years, and now holds six out of the top 10 positions, with three of them being 5-star rated cars.

Seconding Uhlarik, Sanjeev Ghosh, Senior Technical Specialist, Autodesk India said that traditionally simulation tools have been resource hungry. Looking to tap the opportunity in the segment, Ghosh claims that his company is working on balancing functional requirements and structural components. "We are looking at identifying the constraints involved in materials used and methodologies. By enabling designers to leverage the power of the Cloud where machine learning helps take the load off them, our simulation suites & solutions allow them to do many things at the same time." He explained that the direct conversion between ICE and EV has largely happened in auto industry and now the efforts are being made to bring differentiation into design and efficiency of the vehicles.

Offering perspective from component suppliers' side, Santhosh Jacob, Director & Country Manager, Igus India opined the car cabin is literally the second home, therefore needs to be a silent zone as far as possible. "There is a growing interest from OEMs in vehicle weight reduction. With sharper focus on EVs, they are also keen to reduce noise. In terms of reducing the number of components, plastics help OEMs & Tier 1s do that," said Jacob highlighting that Igus conducts tests on about 500-800 compound compositions annually. Currently these are extruded and tested in Germany because low volume demand in India presently does not make business sense for producing it locally.

RELATED ARTICLES

Cosmo First diversifies into paint protection film and ceramic coatings

The Aurangabad, Maharashtra-based packaging materials supplier is leveraging its competencies in plastic films and speci...

JSW MG Motor India confident of selling 1,000 M9 electric MPVs in first year

The 5.2-metre-long, seven-seater luxury electric MPV, which will be locally assembled at the Halol plant in Gujarat, wil...

Modern Automotives targets 25% CAGR in forged components by FY2031, diversifies into e-3Ws

The Tier-1 component supplier of forged components such as connecting rods, crankshafts, tie-rods, and fork bridges to l...

01 Dec 2021

01 Dec 2021

5020 Views

5020 Views

Autocar Professional Bureau

Autocar Professional Bureau