Schuler rolls out fastest press line in the world

The fastest press line in the world – the Servoline L Schuler – has gone into operation at a German premium car manufacturer yesterday.

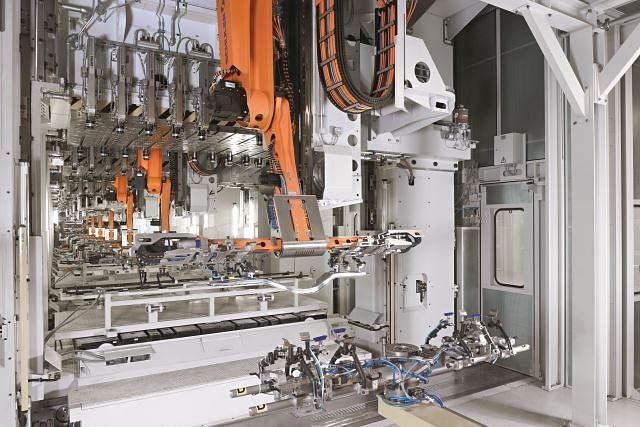

The fastest press line in the world – the Servoline L Schuler – has gone into operation at a German premium car manufacturer yesterday. Equipped with platinum loader, Crossbar Feeder and an end-of-line system, the compact system delivers up to 23 strokes per minute. The direct servo technology ensures not only a high output but also enables flexibility, energy efficiency and low unit costs. The new line is designed for the production of steel and aluminium components while higher-strength steels can also be processed reliably and quickly, according to the company.

"The Power Line L Schuler makes a significant contribution to the efficiency of modern stamping plants,” says Klaus Linnig, managing director of Automotive Schuler. "We were able to achieve a production rate of this magnitude only because we have designed the Crossbar Feeder for fast and safe transportation of double and quad parts from scratch."

Schuler - highly dynamic servo motors increase the output, flexibility and energy-efficiency and reduce unit costs

In the first step, two crossbar Schuler robots alternately handle the unstacking of tailored blanks and place them on a conveyor belt. The boards are washed, if necessary, oiled and then fed to the optical centering. A camera determines its location and transmits the values of two robots, the position then exactly sent to the boards so that the Crossbar Feeder can precisely install in the first press. To guarantee the highest possible quality of the formed parts, the drawing press is equipped with a servo-hydraulic table cushion.

The crossbar feeder then transports the components from press to press. The new development compares favourably to the previous two additional servo axes in order to reorient and double parts. The user can independently pan, rotate or move transversely to the direction required. The flexible bearing change offers completely new design possibilities.

Tooling in just three minutes

Schuler has designed the Crossbar Feeder for fast and safe transportation of double and quad parts from scratch.

After the last forming the crossbar feeder passes the components of a shuttle. There, two robots take the finished body parts to place them on conveyor belts. The fully automatic machine tools and tooling can be implemented in just three minutes and allows fast changeover times, which are critical for flexibility and efficiency in a press shop.

RELATED ARTICLES

Autoliv Plans JV for Advanced Safety Electronics With China’s HSAE

The new joint venture, which is to be located strategically near Shanghai and close to several existing Autoliv sites in...

JLR to Restart Production Over a Month After September Hacking

Manufacturing operations at the Tata Group-owned British luxury car and SUV manufacturer were shut down following a cybe...

BYD UK Sales Jump 880% in September to 11,271 units

Sales record sets the UK apart as the largest international market for BYD outside of China for the first time. The Seal...

22 Jul 2014

22 Jul 2014

9254 Views

9254 Views

Ajit Dalvi

Ajit Dalvi