Indian and German auto forums target greener motoring

An excerpt of the seminar that was participated by ACMA, SIAM and Germany's VDA.

India’s ACMA and SIAM along with Germany’s VDA recently held a seminar in New Delhi on future options of propulsion technologies where industry experts debated solutions which could help transform how people drive, plan commutes, refuel cars and live in a cleaner and healthier atmosphere.

The automotive industry the world over is witnessing what could historically be classified as its most dynamic phase ever, with a slew of transformations and major tectonic shifts lined up ahead, in a bid to move towards a sustainable tomorrow. The technology-intensive Germany and India, a sizeable volumes market, are certainly in the thick of the action and getting prepared for a dynamic future.

L-R: Vinnie Mehta (podium), director general, ACMA; K K Gandhi, executive director, technical, SIAM; Dr Martin Koers, head of economic policy and climate protection, VDA; Abhay Damle, joint secretary, MoRTH; and Dr Jasper Wieck, deputy head of mission, Embassy of the Federal Republic of Germany.

Where Germany encompasses all major vehicle manufacturers and component suppliers under one unified body – the German Association of the Automotive Industry (VDA) or verband der automobilindustrie as it stands for, India sees the two subsets of its automobile sector being part of individual associations, namely ACMA and SIAM. With a fair amount of similarities in the status quo on the future of fossil fuels, primarily diesel in both the countries, the VDA, ACMA and SIAM are seen coming together, collaborating and generating ideas to research in the space of future mobility solutions.

VDA's Dr Martin Koers: "We have to strictly aim at reducing vehicular emissions and e-mobility is one of the alternatives."

A capacity building workshop between ACMA and VDA in the first week of January 2018 marked the curtain raiser to the new calendar year. In their effort to continue deepening the longstanding cooperation between the two countries, the three governing bodies held a joint seminar on future options of propulsion technologies for on-road mobility, in New Delhi, on January 9.

German Embassy's Dr Jasper Wieck: "The auto sector contributes one-fifth of the total FDI made by German companies in India."

While the German automotive industry is looking to make its complete vehicle fleet emission-free by the middle of this century between 2050 and 2055, Indian industry is still coming to terms with the whammy from its government, which has laid a roadmap to target complete vehicle electrification within the next decade by 2030. Back in Germany, where the infamous Volkswagen diesel emission scandal from the recent past has also initiated some thought on the lines of banning diesel-powered vehicles from some of its cities, India too saw big diesel vehicles being abruptly banned in its capital city – New Delhi – for some period in 2016. The similarities extend just a little bit more, what with India slated to adopt BS VI emission norms, the local equivalent of Euro 6, 2020 onwards.

MoRTH's Abhay Damle: "When BS VI comes in force, the industry can make products which will be ready for the foreign markets as well.”

Speaking at the seminar, Dr Martin Koers, head of economic policy and climate protection, VDA, said, “The German government has a clear commitment towards internal combustion engines as well as diesel engines, and has not yet enforced any ban on diesel-powered vehicles.”

Bosch India's Dr Christian Teich: "The government should re-consider full electrification and closely look at some more alternatives as well."

“We have to strictly aim at reducing vehicular emissions and in that case, e-mobility is certainly one of the alternatives. However, the automotive industry as well as the government, along with its political ecosystem will need to collaboratively work towards electric mobility,” he added.

He quoted German Federal Chancellor, Angela Merkel, who had voiced her opinion on the future of traditional engines in September 2017 and had said, “The challenges for Germany are visible strongly in the automotive industry. Decades are still needed for combustion engines, but, at the same time, the path to newer driving technologies and digitalisation must be taken.”

STRONG PARTNERS IN PROGRESS

Also part of the opening session, Dr Jasper Wieck, deputy head of mission, embassy of the Federal Republic of Germany, shed light on some of the common concerns being faced by the two nations, including standing on the verge of facing a possible lack of resources in the future, as well as taking joint efforts together in larger political causes, for instance, fighting international terrorism. “Indo-German partnership goes a long way in the area of science and technology as well, where we are collaborating in research at the academia level, and, if we look at our industrial collaboration, then, over 1,600 German companies are currently represented directly in India.”

Mahindra & Mahindra's Senthur Pandian: "Vehicle electrification in India is going to realistically touch 35-40 percent by 2030."

“The automotive sector plays a crucial role as it contributes one-fifth of the total foreign direct investments made by German companies in India,” he added.

“The presence of German companies in India is also relevant to the government’s various key missions like the Make-in-India program, where numerous German automotive companies are not merely operating by having a retail presence in India, but also locally producing these parts and vehicles here, and even exporting them abroad.

NITI Aayog's Anil Srivastava: "E-mobility is a severe inevitable disruption which is going to take place. Things are moving very fast."

“The Skill India initiative is another area where the automotive sector is playing a huge role and a number of German automobile majors, including Volkswagen, are contributing to the program by setting up their skill development centres and imparting training through programs in conjunction with various schools and ITIs. Moreover, Euro 6 emission technology developed by some of the major German component suppliers aligns with the government’s Swachh Bharat progam, and will be used to direct the Bharat VI emission norms in India, when they come into play in 2020,” said Wieck.

BS VI as an opportunity

While it is hugely challenging for the Indian industry to be leapfrogging an entire generation of emission norms, and adopting BS VI norms by 2020, according to Abhay Damle, joint secretary, Ministry of Road Transport and Highways, “Once the BS VI standards come into place, the automotive sector would relish all the magnanimous efforts gone into its implementation, as it will then be able to produce common products which will be simultaneously ready for the foreign markets as well.”

CharIN India's Sivam Sabesan: "Apart from the Centre, corporations could install EV chargers as part of their CSR initiatives."

“While India will need to eventually drive the road to electrification, however, in the short-term, the auto industry has to look at upgrading to the new emission norms in the pipeline and the industry will have to allocate more resources to attain both the forward setting goals,” he added.

With the government’s gradual push in terms of setting up an EV-charging infrastructure in the country, other aspects like the upcoming newer Real Driving Emissions (RDE) validation tests would also go a long way in curbing vehicular pollution, where statistically, it is the commercial vehicles which are the largest emitters, gulping around 60-70 percent of the total fuel consumption in the country, while merely accounting for just 2.5 percent of the total vehicle population.

“Vehicle emissions under the proposed RDE tests for 2020 should be fuel agnostic and should not reflect a considerable difference between emission values of different fuels,” said Damle.

“Looking at electrification, research and innovation to recycle lithium from batteries should also be undertaken at the onset of development of electric vehicle solutions as that is going to become the next bigger challenge, once EVs start getting embraced in large numbers.

Maruti Suzuki India's Tapan Sahoo: "Along with incentives for EV buyers, the government should support EV component suppliers."

“Also, India sees a very high variation in its ambient climatic temperature, and hence, occupant safety inside an EV should be one of the key focus areas for all such products being developed for our market,” added Damle.

Over 6 billion people are estimated to be dwelling in cities around the world by 2050, clearly hinting at a surge in vehicular traffic in confined areas which could triple over these years. From an India perspective, the country is set to become the third largest automotive market in the world by 2030 and will witness strong growth on the basis of affordable products. Shared mobility is also on the rise and will see a 25 percent CAGR by 2020.

While growth is always good, the speculated rise in volumes of these mobility products also holds a sustainability threat in the form of rising emissions and greenhouse gases, and, given the size and scale of the problem, e-mobility will just not be a standalone solution for an expansive nation like India, when there are multitude of other angles which need attention, for instance, 60 percent of the country’s power is being generated from poor quality coal, and this concern lists right at the top. Moreover, vehicles older than 10 years contribute to roughly one-third of the total vehicular emissions and there is no concrete scrapping policy for such vehicles in the country as of yet.

According to Dr Christian Teich, vice-president, Head of Development, Bosch India, “If we extrapolate the emissions coming from Indian power plants in a scenario that around 60 percent of the country’s vehicle parc becomes electric by 2030, then, there would be around 760 percent more NOx emissions and a dreadful 6,200 percent more PM emissions due to power generation from low-grade coal. Thus, electro-mobility alone will just not solve the problem in India, and even though the Indian government is looking ahead to bring a shift by enhancing its renewable-sourced power, substantially scaling it up from being at 21 percent presently, it is set to require at least a few decades to revolutionise the complete power generation system in the country.”

“On the other hand, EVs are also not environment-friendly per se when the complete picture is viewed closely. Compared to a 2.0-litre Euro 6 diesel engine, it is only when we bring down the battery range on an EV to less than a 100km, that it indirectly emits on-par with such advanced levels of conventional fuel technologies.

“Hence, it would be better for the government to re-consider full electrification and closely look at some more alternatives as well, also shedding some more clarity on the roadmap soon, which would help in setting a direction for the automotive industry in the country,” Teich added.

Cost effective emission reduction technologies like variable oil pumps and thermo-management systems also stand relevant to cut down CO2 emissions by up to 11 percent.

With the Paris Accord defining an 11 percent CO2 reduction target for countries to cut down on their exhaust emissions, being a signatory to the accord, India also needs to overcome bigger technological and socio-economic challenges lying ahead of the nation, wherein improper driving habits of lugging the engine in higher gears for the sake of getting better fuel efficiency, and its traffic infested cities, are just some of the impediments to a cleaner future.

The IC engine is being constantly improvised with incessant research towards making these conventional engines more efficient. Modern solutions are already out, where they could offer substantial emission reduction. “Around 25 percent of the CO2 emitted can be reduced by optimising EGR gases going into the turbo, along with achieving a 68 percent reduction in NOx and 82 percent lowering of the emitted particulate matter (PM) in a forced-inducted petrol or a diesel engine. Tyre wear, brake and street abrasion are the other factors, which, however, will continue remaining common PM sources for both EVs as well as conventional vehicles.”

“Implementation of cost-effective technologies including variable oil pumps and thermo management systems can also reduce CO2 emissions by up to 11 percent. While the cost increment in equipping a vehicle with these emission reduction technologies varies between 8-19 percent across vehicle segments, it will, however, benefit the end customer in the form of considerable reduction in the long-term total cost of ownership, along with reducing the per capita CO2 emissions,” remarked Teich.

Hybridisation, synthetic fuels and Euro 6 offer a balanced mix

With a list of challenges towards complete electrification, hybridisation emerges as being a sensible transition technology going forward. “India is likely to see over 80 percent of the vehicle parc comprising hybrid IC-engine vehicles and not purely electric cars by 2030. Synthetic fuels, like methanol, which are made from bio-degradable compounds, are also very important in driving towards a sustainable future”, added Teich.

While Germany's CO2 emissions currently stand at 118.1gm/km, the target all across Europe is to reach 95gm/km by 2021, else the component and automobile manufacturers are looking at getting heavily penalised.

According to Dr Martin Koers, “A climate protection policy should not be narrowed down to being applicable only to new vehicles; instead, it should also take into account the older vehicle stock. While moving towards electric-mobility there needs to be a viewpoint, wherein one doesn’t only look on the propulsion technology, but, also look holistically at the overall change, including the need to revamp the power infrastructure.”

“Even the European authorities need to think along these lines and not just try and run into the future with just one technology. The industry, united within VDA is looking at moving forward by optimising the internal combustion engine and not just completely shifting to electric technology immediately.”

“Europe has also laid out targets beyond 2021 and is looking at 15 percent CO2 reduction by 2025, enhancing it to 30 percent by 2030. Emission reduction does not strictly follow a linearity curve and the current targets set by the government are not acceptable to the VDA, especially the first milestone for 2025. The government could consider adopting a different methodology, as it will also help for an easier interplay between new European driving cycle (NEDC) and the worldwide harmonised light vehicle test procedure (WLTP) tests, introduced in September 2017.”

“Moving towards e-mobility also means a thorough look from a socio-economic perspective, when the entire vendor base, which, today, relies on internal combustion engines would also need to be kept in prime consideration while making policy changes.

“The government should not be fixated when rolling out a future roadmap; it should only set emission targets and not be technology biased. On the other hand, the industry should also be looking at consistently updating the current technology, as well as developing newer synthetic fuels, which can be formulated with bio-degradable waste compositions and abundant sunlight.

“Around 46 percent of the cars in Germany are diesel powered and contribute to a CO2 emission level of 126.5gm/km. If they were to be replaced by only petrol driven vehicles, the CO2 emissions would go up to 132gm/km. On the other hand, with a 100 percent Euro 6 diesel fleet, it would still be 119gm/km. Hence, disregarding diesel is not the right way forward. The auto industry has already set examples by reducing over 70 percent NOx content in vehicular emissions with the advent of cleaner diesel technology since 1980.

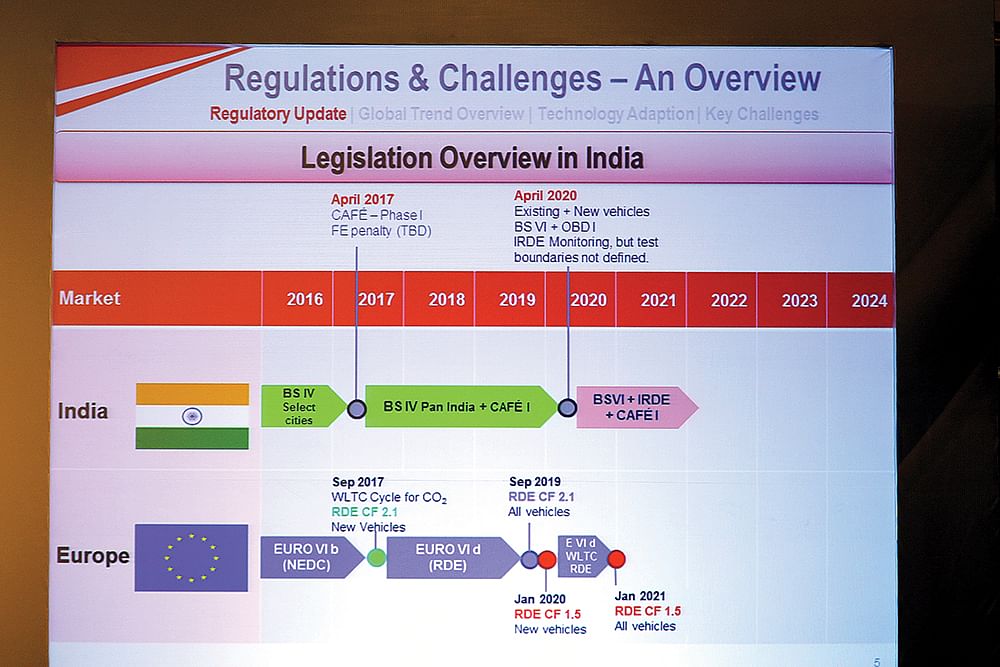

After witnessing the implementation of BS IV norms across the entire country only by April 2017, India has the gigantic task of catching up with the world within the next two years.

“Having said all of that, we are convinced that electric technology is relevant in the longer run, and will have to eventually arrive in a gradual manner, but not disruptively,” Koers concluded.

Regulatory challenges in India are set to be in force, with the BS VI emission norms and RDE testing both coming into play by 2020. With roughly 80 percent reduction in NOx content, BS VI vehicles are going to be classified under M Class emission category in the ARAI’s emission testing categorisation.

While the work is on since February 2017, absolute clarity on RDE is expected to be rolled out only by June-September 2018. Moreover, CAFE Phase I to Phase II reduction is also going to see stricter targets with close to 17 percent emission reduction.

According to Senthur Pandian, associate chief engineer (Powertrain Division), Mahindra and Mahindra, “With the current projections, vehicle electrification in India is going to realistically touch 35-40 percent by 2030. Diesel will continue to see somewhere around 27 percent penetration by 2030 and 18 percent in case of faster adoption of e-mobility. Taking the well-to-wheel consideration, BS VI diesel will emit 115gm/km, while on the other hand, an electric car will not be dramatically far away at 107gm/km,” he added.

Exhaust after-treatment is also set to bring down PM emissions by 93 percent by use of diesel particulate filter (DPF) in BS VI. High temperatures in the range of 550 to 600deg Celcius will be required to burn all the soot in a DPF. However, with average city driving speeds in India ranging between 8 to 10kph, there would be the need for 30 percent more regeneration cycles than Europe, where they range between 22 to 25kph.

“India also has a diverse landscape across its territory, including far-flung mountainous areas and any technology which goes into the vehicles should be able to reliably work in all the places, when in the hands of a customer.

“Selective catalytic reduction (SCR) and lean NOx treatment (LNT) are also extremely relevant technologies, depending upon the power-to-weight ratio of a vehicle or its cubic capacity-to-weight ratio. The DPF technology that is going to emerge is also very fuel sensitive and will require good quality fuel, thus, making customers shell out more for getting a cleaner and better quality fuel.

“IC engines will continue to play a very key role in the Indian market, where right blend of powertrain technologies, including affordable hybridisation levels and use of synthetic fuels will remain relevant in the near future until e-mobility is fully set into place," added Pandian.

e-mobility: an inevitable disruption

With incentives in the form of the FAME scheme, which aims to provide a fillip to EV sales in the country, having been in place for some time, India still has some long distance to cover in the form of infrastructure development for e-mobility, before it could see EVs being embraced in a fashion, as they have started picking up in some markets abroad.

According to Anil Srivastava, advisor (transport), NITI Aayog, “E-mobility is a severe inevitable disruption which is going to take place in the future. Things are moving very fast and the rate at which charging infrastructure is being set up in some countries is mind-boggling. India has to keep pace with the rest of the world. FAME is being implemented by the Department of Heavy Industries in India and with the projected growth of the Indian automotive industry, electric mobility which is going to sweep the world is certainly going to affect India as well.”

“A lot of vehicles are manufactured and exported from India, and there is a tremendous opportunity for local production of electric vehicles and batteries. While batteries today contribute 39 percent to the cost of an EV, over 9 percent of that is comprised by battery packaging, while the remaining 30 percent comes from the cells itself. While we can start things by localising the 9 percent in India, cell technology is also changing rapidly and research is already on towards developing newer cells including bio-degradable ones,” Srivastava added.

Analysing the current scenario of vehicle propulsion in the country, where refined petroleum liquids including petrol and diesel today have a share of over 90 percent in final energy consumption for road transportation, SIAM also recently formulated a white paper on EV technology, which projects another 17 years beyond the government’s 2030 vision for India to be able to completely electrify its entire vehicle fleet by 2047.

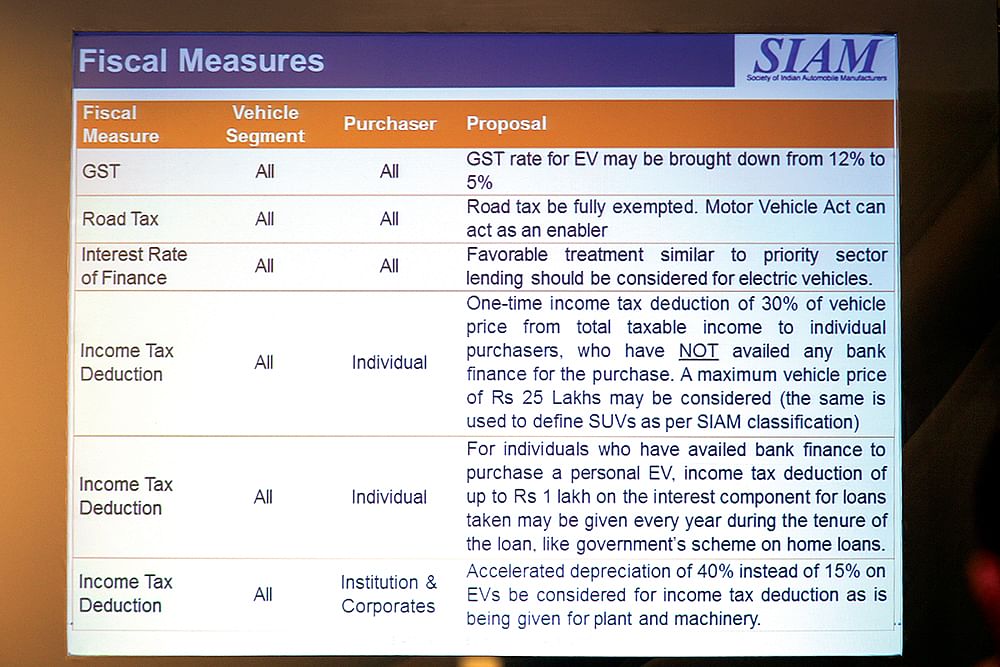

SIAM has made pointed recommendations to the government to drive EV sales in the country.

While government support will be key in setting the momentum for moving in a new direction, according to Dr Tapan Sahoo, chairman, SIAM Group on e-mobility and SVP - Engineering, Research, Design and Development – Maruti Suzuki India, “The state must look at giving clear incentives to push the electric vehicle segment by offering certain benefits like discounted road taxes, income tax rebates, and lowering of the GST slab for EVs from the current set 12 percent to 5 percent. Also, providing support to the local vendors for developing, manufacturing and supplying EV components should also evolve the entire EV ecosystem in the country.”

Infrastructure development again plays a big role and according to Sivam Sabesan, managing director, CharIN India, “Setting up of charging infrastructure, both AC and DC chargers, will also help in driving e-mobility. Apart from the government, corporations could also be motivated to come forward and aid putting up such chargers as part of their CSR initiatives, getting company tax incentives in return.”

With Europe and the US following the combined charging system (CCS) standard, China with its GB/T, Japan with the CHAdeMo and Tesla being on its own proprietary standard, the present day does not see a common consensus among nations as regards charging standards for EVs. While the standards define the current, phase and voltage specifications coming out of this equipment, they also set guidelines for use of AC or DC current or both.

While CCS – I is valid in single phase countries like the USA, Canada and Korea, Europe and the rest of the world are likely to adopt CCS-II. CCS-I is also a bit more flexible in the sense that it allows AC and DC charging on the same socket, thus, helping companies to optimise costs by using the existing fuel lid slot in a vehicle’s design to perform the role of concealing the charging slot, thus, optimising tooling costs.

EVs are going to become a reality, the question being how soon that happens. Vehicle to grid communication, electronic payments, automated load management and reverse power flow from car to grid for grid stabilisation are also some of the operational benefits of electro-mobility and vehicle charging, which will see a complete transformation of how we drive, plan our commutes, refuel our cars, and last but not the least, breathe cleaner and healthier air.

(This article was originally featured in 1 February 2018 issue of Autocar Professional)

RELATED ARTICLES

RSB Group Prepares for Hyper-Growth: New Markets, Tech and Mission ₹10,000 Cr

From a small workshop in Jamshedpur to an engineering group with global reach, RSB Transmissions is preparing for its mo...

Beyond Helmets: NeoKavach Wants to Make Rider Airbags India’s Next Safety Habit

As premium motorcycles proliferate and riding culture evolves, an Indo-French venture is betting that wearable airbags, ...

Inside Mahindra Last Mile Mobility’s Rs 500 Crore Modular Platform Strategy

Mahindra Last Mile Mobility has launched the UDO, an electric three-wheeler built on a new Rs 500-crore modular platform...

03 Apr 2018

03 Apr 2018

16141 Views

16141 Views

Darshan Nakhwa

Darshan Nakhwa

Shahkar Abidi

Shahkar Abidi