Mahindra open to making EV batteries in India with a global partner

Mahindra & Mahindra, which has the largest electric product portfolio in India, now eyes battery manufacturing in India with a global player.

With the Union Budget 2019 showing a marked preference for electric mobility in the automotive scheme of things, one of the prime beneficiaries of this form of green motoring will be Mahindra & Mahindra.

Having acquired the pioneering EV manufacturer Reva Electric Car Company in 2010, the company has since then expanded into manufacture of the entire electric powertrain at its state-of-the-art plant in Bangalore.

In a post-Budget interaction, Dr Pawan Goenka, managing director, Mahindra & Mahindra, expressed his optimism on the government's stand to drive localised manufacture and sale of EVs in the country. "I am happy that the government has come out with announcements to help drive EV sales in the country."

Responding to the additional tax deduction of Rs 150,000 on the interest paid on loans for EVs, Dr Goenka, said he "wasn't sure if this would apply for fleet buyers or personal buyers."

Dr Goenka: "We have been counting on EVs becoming popular in India. The onus is on the Indian automotive industry to now make the EV programme a reality.”

Dr Pawan Goenka, who has been a driving force for electric mobility in the country, said: “We have been counting on EVs becoming popular in India. EVs are a one-time opportunity for India and thus far we (the government) are doing everything right. As an industry, I cannot ask for more. In all fairness, the onus is on the Indian automotive industry to now make the EV programme a reality.”

Pointing out that electric three-wheelers have real potential to lead the charge in the Indian market, Dr Goenka said that probably at present an e-three-wheeler fleet operator could offer considerably more savings per month than one using conventional-fueled three-wheelers. “Viability is the best way of spurring the EV market,” said Dr Goenka.

However, he remarked that the industry will take some time to meet demand for e-three-wheelers. At present, a total of half-a-million conventional three-wheelers are produced each year and 50,000 of them sold every month. Mahindra Electric has a manufacturing capacity of 1,000 e-three-wheelers a month, so it will take the company and the industry some time to ramp up.

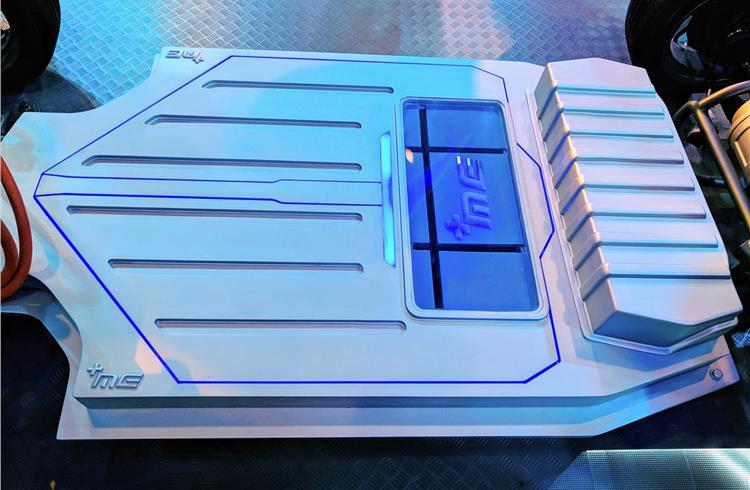

EV affordability through making li-ion batteries in India

The FAME II norms which came into effect from April 1, 2019 puts sharp focus on localisation, so much so that at present only 7 OEMs have a product that qualifies for receiving incentives/subsidy under the scheme. In fact, Mahindra is one of the OEMs whose electric four- and three-wheeler products qualify for the same.

What’s more Dr Goenka, says at present Mahindra Electric has a localisation level of around 60 percent; lithium ion cells, which are not manufactured in India, constitute the maximum value in terms of import. Localisation of lithium ion cells would bring down EV costs and reduce the country's reliance on expensive imports.

Interestingly, early in June 2019, plans for Europe’s first homegrown gigafactories for lithium-ion batteries were announced. The first one will be set up by Northvolt, a European supplier of sustainable, high-quality battery cells and systems, in Skellefteå, Sweden. Building construction work will commence in August with large-scale production estimated to begin in 2021. Northvolt Ett will serve as Northvolt’s primary production site, hosting active material preparation, cell assembly, recycling and auxiliaries. The gigafactory will be expanded to at least 32 GWh.

A second gigafactory with an intended location in Lower Saxony, Germany is also planned. A JV between the Volkswagen Group and Northvolt will be set up to establish a 16 GWh battery cell gigafactory in Germany. Volkswagen is investing around $1 billion (€900 million) in joint battery activities with Northvolt.

The Tesla Gigafactory. In mid-2018, battery production at Gigafactory 1 reached an annualised rate of roughly 20 GWh, making it the highest-volume battery plant in the world. Tesla currently produces more batteries in terms of kWh than all other carmakers combined.

M&M "open to partnership" with li-ion battery cell maker

Responding to a query whether Mahindra would be willing to set up its own lithium ion cell/battery plant, Dr Goenka said that this part of the EV eco-system is not one where Mahindra has expertise, but is “open to partnership with a global player keen on setting up a lithium-ion cell manufacturing operation in India.”

Typically, setting up a lithium-ion cell plant takes 2-3 years to set up. For India, only a mega factory or a Tesla-like Gigafactory would make sense to be future-fit.

This is an area similar to what the Finance Minister announced today, that India would benefit from setting up mega plants for semi-conductor fabrication (FAB), solar photovoltaic cells, lithium storage batteries and solar electric charging infrastructure. What’s more, in the light of the ongoing trade tension between the USA and China, Dr Goenka is bullish that India can play a bigger role to gain from large-scale manufacturing for the domestic as well as export markets.

The Top 10 lithium-ion battery manufacturers in the world are Samsung SDI, Panasonic, Toshiba, LG Chem, Tesla, A123 Systems, eCobalt Solutions, BYD, Contemporary Amperex Technology and Johnson Controls. Would any of them be interested in partnering Mahindra Electric in setting up a giga factory in India?

E3W registration hiccups, but Mahindra remains bullish

The government has been mulling a proposal to mandate sales of only electric three-wheelers and two-wheelers (under 150cc) starting from 2023. According to analysts, the cost of a three-wheeler in the BS VI era will make it more expensive compared to its electric counterpart (including subsidies), an opportunity that Mahindra can look to drive sales of the Treo, its electric three-wheeler launched in December last year. Dr Goenka agrees, that with the technology upgrade, the cost differentiation between a BS VI-IC-engined three-wheeler and electric three-wheeler will tip the scales in the favour of the latter.

But what seems to be a temporary pain-point, he revealed that despite the central government and state government's push for EVs, the local transport authorities were finding it difficult to issue permits for the green vehicles. As a result, despite a strong demand the sales of Mahindra Treo has not reached its potential.

Responding to a query on the government's space programme agency ISRO devloped lithium-ion battery potential, Dr Goenka, said: "We do not have the details of the composition and usage of the battery in electric vehicles, but if in case it meets the needs and is cost competitive we would definetly explore the idea."

Also read: Union Budget 2019 makes EVs cheaper, petrol and diesel see Rs 2 hike

Tough FAME II norms see only 7 OEMs qualify for incentives

Mahindra breaks ground on new EV powertrain plant in Chakan

Mahindra bets big on e-mobility, opens new EV tech plant, launches Treo 3W at Rs 136,000

RELATED ARTICLES

Tata Elxsi-Renesas MCU for EVs enables cost optimisation, speedier time to market

Modular, scalable design of Motor Control Unit enables integration across diverse EV applications. Claimed to be reduce ...

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

05 Jul 2019

05 Jul 2019

56878 Views

56878 Views

Autocar Pro News Desk

Autocar Pro News Desk