Altigreen Propulsion Labs eyes potential boom in India’s EV market

Bangalore-based start-up, with over 17 global patents to its credit, is bullish on supply of complete electric drivetrains for two-, three-, and four-wheelers to EV makers.

Start-ups in India are an ongoing growth story, each with a mission of its own. Bangalore-based Altigreen Propulsion Labs, set up in 2011 by four entrepreneurs – Dr Amitabh Saran, Shalendra Gupta, Dr Lasse Mocklegaard and John Bangura – with an initial goal to develop retrofit solutions for petrol and diesel-powered vehicles to convert them into hybrids.

While Dr Amitabh Saran, co-founder and CEO, focuses on R&D, engineering and customer engagement, Shalendra Gupta, co-founder and CFO, spends time in production, finance and corporate affairs. The other two founders — US-based Dr Lasse Moklegaard and Dr John Bangura — assist with research on cutting-edge technologies and advise on design of new drivetrain systems.

The start-up, which initially began life by improving fuel efficiency of conventional engines by up to 20 percent, by implementing hybrid-drive regenerative braking. At the time, a pure hybrid like the Toyota Prius used to cost Rs 30-odd lakh wih few takers for a hybrid solution. Thus began the shift to developing full-electric drivetrain solutions for future EVs, a path the Indian government was also seen driving at aggressively.

Speaking exclusively to Autocar Professional, Dr Saran says: “We decided to continue and have a plethora of drivetrains for different applications. What we soon realised is that the way to success in India is to focus on the lower end of the pyramid.”

The company now designs and fabricates EV components at its research lab and also manufactures motors in a nearby factory. In 2015-16, Altigreen was approached by OEMs from across vehicle segments to build drivetrains for their future products but the start-up was clear that it would do everything in-house, and keep the IP its own. The brief three-year stint at designing hybrid solutions helped it master system intelligence by logging onto the data accumulated, which it was later able to leverage in its electric drivetrain solutions.

“While there is a need for making the shift to electrics, start-ups and the non-traditional guys are the ones who are going to make that happen,” says Dr Saran. “We are non-conformists and don’t go by pure physics or chemistry,” he adds. The company is building innovative components suitable for e-two-wheelers and e-three-wheelers, which will be the first adopters of e-mobility in the near future. The team feels that it is in an advantageous position of having staffers with the desired competencies but without the prolonged experience of being conditioned in a conventional automotive setup. “All of us have worked in the automotive industry but never at a stretch to become comfortable,” says Dr Saran. The start-up has a total of 45 people with engineers coming in from their earlier roles at L&T, John Deere, Bosch, Qualcomm and Hero, among some big names.

Building the EV powertrain

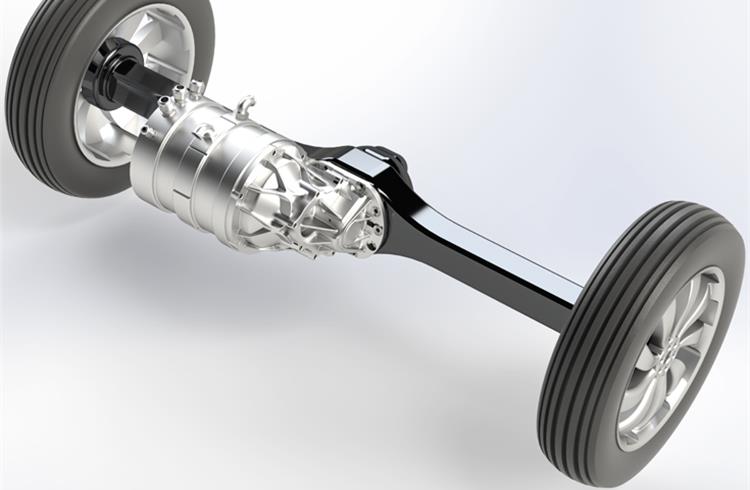

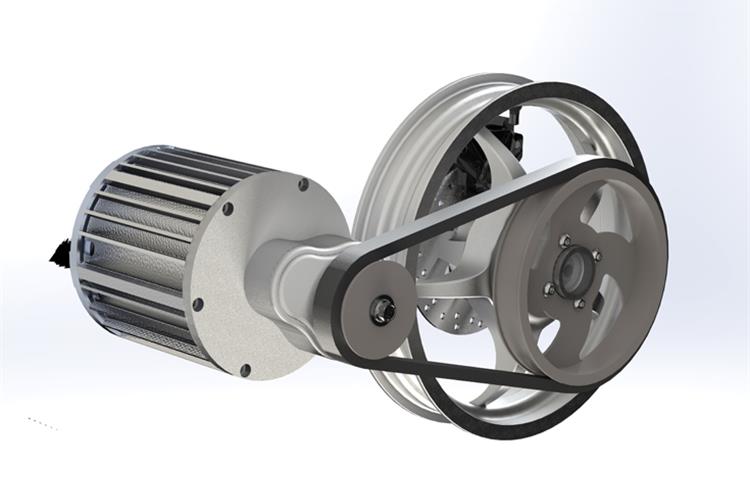

Altigreen is developing and building the motor, controller, ECU, DC-DC converter, full EV gearboxes, battery BMS and telematics along with the sensors and has a number of prototypes with these components installed and tested to prove the concept’s case.

The company says that focal point of all things is the customer who is going to drive or ride the vehicle. "Chinese imports are all 60-72V or higher rated, which means transmission of lower current and hence, being able to run an EV on fairly poor wiring which can only handle low Ampere current. In comparison, we have standardised most of our systems to operate at 48V, which ensures robustness of the electrical architecture, while keeping in line with international standards," explains Dr Saran. The company has has adopted liquid cooling techniques to manage the thermal dissipation for some of its bigger CV drivetrains.

Altigreen has developed its electric solutions for three-wheelers, both cargo- and passenger-carrying, up to payload capacities of 350kg, which Altigreen thinks is the perfectly suited category to make an immediate shift to electric technology. It has developed its cargo-carrying prototypes on multiple OEM platforms and with its e-axles, the same for a passenger-carrying three-wheeler as well, which is in testing phase and taking rounds in Bangalore to gather more usage-based data.

Big manufacturing plans and 17 patents

Altigreen Propulsion Labs plans to manufacture the drivetrain at its adjoining facility. Winding of the motor is the most critical task. While the start-up procures the die-cast housing from a vendor, the winding of the motor and its balancing are done in-house with a total installed capacity of 300 units every month.

With the rotor spinning at 10,000rpm, the air gap between the rotor and the stator is only 0.3 microns and hence, the quality and balancing need to be fool-proof so as to not make the motor a dangerous device. There is a 5kW integrated combo-drive for scooter application; a 9kW e-axle compatible with CV shaft for passenger-carrying three-wheelers and a 17kW e-axle for small CV application, basically a cargo-carrying three-wheeler. With its multitude of innovations bundled in, Altigreen has been granted 17 patents thus far, in various countries including US and Europe.

The limiting factor in its current production capacity is only the winding — Altigreen does 100-120 units a month with only two people working in this manual operation. The unit is contributing to pilot projects coming in from fleet operators and last-mile delivery companies, for instance, those catering to e-commerce players.

Believing strongly that demand will pick up in the near future, Altigreen plans to set up a larger capacity plant in Bangalore which calls for Rs 40-50 crore in capex. "The new facility should be up and about in 12-15 months' time and will cater to OEMs, starting with three-wheeler companies," says Shalendra Gupta. The company will then be able to produce close to 3,000 drivetrains in a single-shift pattern and 6,000 units over two shifts each month.

While the start-up has, till now, raised a few million dollars (in single digits), it believes this is a small amount for the kind of work it has done till now. Altigreen has an electric solution for scooters, motorcycles, auto-rickshaws and mini-trucks from 2kW all the way up to 40kW.

“We were very clear that an EV has to compete in price and performance with conventional-powered vehicles and doesn’t inconvenience the user, either in terms of usage or acquisition. We are doing this completely in India and the technology has been developed, tested and manufactured in India as well. The local content in our solutions is more than 80 percent,” affirms Gupta.

“OEMs are paying us money to develop drivetrains for them. While the IP remains with us, we are not a design house and won't just design a solution for an OEM. Rather, we will supply the final product,” signs off Gupta.

For more interesting EV start-up stories, read Autocar Pro's August 1 South India Special

RELATED ARTICLES

Ford to build more EV software capability at Chennai tech hub

Ford Business Solutions India, which currently employs 12,000 personnel set to add 3,000 more; Ford, which is known to b...

ASK Automotive to set up JV with Aisin to sell aftermarket parts for cars

Ask Automotive will have 51% of the equity of the joint venture to be set up with Aisin Asia (Thailand) Company and Aisi...

Kia Carens gets 3-star Global NCAP rating in fresh tests

The Carens MPV, which was tested twice under the new protocol, scored zero stars for adult occupancy in the first test.

05 Aug 2019

05 Aug 2019

26297 Views

26297 Views

Autocar Pro News Desk

Autocar Pro News Desk