Ion Energy, Europe’s Wamtechnik to enable development of electric excavator

Under the partnership Ion Energy has utilised a 48V, 456Ah battery pack to power the primary model of the excavator.

Mumbai-based advanced battery management and intelligence systems provider Ion Energy, has entered into a strategic partnership with European battery manufacturer Wamtechnik to facilitate the deployment of its prototype – an electric excavator for a leading European construction equipment maker.

Wamtechnik is 28-year old European leader in power supply systems, which undertakes the design and production of dedicated rechargeable and non-rechargeable battery packs for industrial applications. The company’s customer is a leading construction equipment and worksite technology builder that is said to have operations worldwide for over a century with high-end applications and innovations. They deliver a wide range of construction equipment that includes wheel-loaders, excavators and ground compacting equipment among others.

The partnership aims to address the dearth of sustainable, zero-emission construction machines that could replace the diesel engine to absolution. With Wamtechnik envisaging the design and deployment of a range of compact electric construction equipment that would operate in subzero temperatures (below -20°C), Ion Energy says it emerged as the project’s key enabler. The partnership enables Wamtechnik to license Ion’s BMS technology platform.

Under the partnership Ion Energy has utilised a 48V, 456Ah battery pack to power the primary model of the excavator. The battery pack is constructed using 10 parallel modules of a 14S16P cell configuration, to achieve the rated energy capacity. Ion Energy says it deployed its cutting-edge tech platform to overcome the foremost project hurdle, identifying a smart battery management system provider who would enable a highly scalable and reliable Master - Slave architecture for batteries manufactured by Wamtechnik. The battery giants configured a battery pack with variants of different energy capacity that would work on all of them without depending on hardware and software customisation.

To solve the gaping problem of accelerated battery life degradation caused by the extremely cold temperatures as low as -20°C that lead to lithium plating, Ion developed and implemented the control of a unique Wamtechnik thermal management system that manages safe operation of a lithium-ion battery at temperatures as low as -40 degree C, where an excavator is expected to function. The system verily powers up the heaters using onboard chargers and brings up the battery to an optimum temperature before its activation.

The Mumbai-headquartered company says it enabled Wamtechnik to electrify their customer’s first excavator and continue to design platform solutions for the customer. Ion has ensured a minimum business of $1 million (Rs 7 crore) for the partner in 2020 that would increase to $15 million (Rs 111 crore) in the upcoming years.

Wamtechnik says it leveraged Ion’s AI-powered battery intelligence platform - Edison Analytics to visualise, predict and interpret battery data to improve battery life and manage their fleet.

Commenting on the collaboration, Filip Gabryelewicz, product manager, Wamtechnik said, “Ion has massively assisted our customer to overcome their critical challenge of operating the battery under extreme temperatures. The support and guidance that Ion’s team offered to us and our customers throughout the project was invaluable. We have been able to significantly boost our business profitability and are confident about working with more customers to solve pressing battery management problems!"

Akhil Aryan, co-founder and CEO, Ion Energy said, “This collaboration with Wamtechnik has been instrumental in realising Ion’s long-term growth and expansion targets and also in ushering emission-free and sustainable electrified automation. The strategic alliance will go a long way in transforming the power supply and construction equipment ecosystem. It will revolutionise and redefine hitherto smoke-producing, manual, and inefficient processes. This convergence of ideal business innovators and pioneering technologies is vital for achieving a global sustainable industrial model that utilises scientific advancement and knowhow to sublimate the impending disasters posed by the deadly climate change and the continual distress primarily induced by ICEs.”

RELATED ARTICLES

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

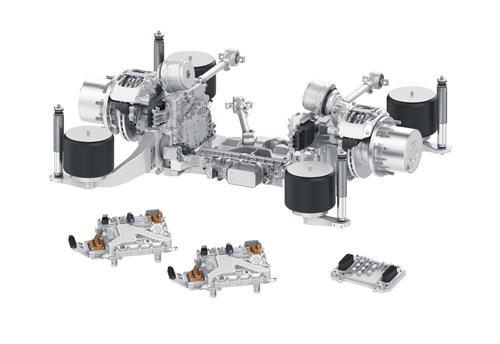

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

By Autocar Pro News Desk

By Autocar Pro News Desk

24 Mar 2020

24 Mar 2020

4752 Views

4752 Views