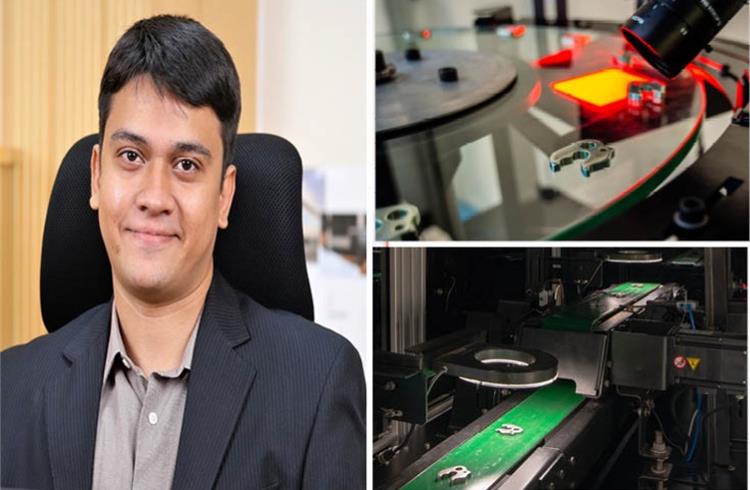

Vinodh Venkatesan: ‘Customers realise upto 50 percent savings by automating visual quality control’

Chennai-based start-up, Jidoka Technologies is offering solutions to automate visual quality checks at high speed by leveraging deep learning.

Today artificial intelligence and machine learning are taking the automotive industry to the next level of efficiency. Deep learning, an AI function, mimics the workings of the human brain in processing data and allows inspection of production components. Chennai-based start-up, Jidoka Technologies is offering solutions to automate visual quality checks at high speed by leveraging deep learning. It has recently received US$ 340,000 seed funding from a leading technology entrepreneur. Vinodh Venkatesan, Co-founder and COO, Jidoka Technologies shares the details.

How will this technology play a role in the automotive industry?

Jidoka QC solutions help to automate the process of visual quality while increasing consistency and accuracy at high speed by leveraging AI (Artificial Intelligence), ML (Machine Learning), deep learning and analytics. In the automotive industry, the solutions are able to detect errors such as dent, damage, line mark, face burr, deburring, colour mismatches, rust and processes that are missed for various types of products. The range of products include assembly and sub-assemblies, casting, ground and machined parts, fine blanking besides hot and cold forging.

Deep learning, a subset of machine learning in AI, is leveraged to teach machines to learn by example. This technology can recognise features that distinguish trends and make intelligent predictions and decisions. It also scales the intelligence of human visual inspection with the reliability, consistency and speed of a computerised system. We use a combination of supervised and unsupervised computer vision AI algorithms. In the low data regime, we use our patented anomaly detection algorithm along with clustering. Jidoka’s automated cognitive QC solutions combine the power of AI with automation and computer vision in defect detection, delivering 98 percent or higher accuracy in the process.

Who are your major customers in the automobile segment?

We are currently working with MudhraFine Blanc (Latch and Pawl – door assembly), Nexteer Automotive (driveline component), Indo Schottle Auto Parts (valve spring retainers), Triton Valves (tyre valves), IP Rings (piston rings) and Rane TRW (clutch cover assembly) in the automotive sector.

What sort of savings (in percentage) and benefits does your software bring? And, what production efficiencies these bring in. Can you share some real time examples?

Jidoka QC solution has both hardware and software components. The hardware platform has three trademarked structural shells – Huron for large-volume complex products, Tigris for flat and lightweight products and Miyake for manual load and unloading with selective checking.

The software platform Kompass marries real-time decision-making AI to create an end-to-end system for visual defect systems. The software provides a turnkey solution that fits seamlessly into the production line of different manufacturers. The system uses a digital twin created by the hardware and maps it to the AI to deliver up to 1,200 decisions per minute, saving costs.

Customers are realising 25-50 percent cost savings year on year by automating the process of visual quality control. Our customers were also able to address the existing challenges by leveraging the solution. To name a few, Mudhra has seen a 33 percent increase in throughput with quality control during the night shift as there has been 24X7 inspection with our solution. IP Rings was able to attain 100 percent accuracy with no customer complaints. Even the end-customer appreciated error-free consignments.

Also other customers had a 5-8 percent increase in accurate detections and decreased their false positives by as much as 30-40 percent. A 20 percent increase in the speed of inspection can be achieved in the product control aspect with inspection as a bottleneck getting eliminated.

How is the technology in India compared to the world?

The Artificial Intelligence we have driven solutions are on par with globally available technologies in the space of computer vision. These cutting edge technologies include deep learning algorithms, advanced image augmentation techniques and leveraging edge computing for high speed decision making on complex problems.

What is the next stage of this technology?

There are two areas we are exploring to further product development.

- Move to a KPI driven triaging of quality, where we manage economic, quality and production constraints and drive incremental change instead of looking at quality in isolation.

- Look at the need for customers to have data to ensure higher levels of accuracy by leveraging the cutting-edge work done in AI/Machine vision such as anomaly detection and 3D image generation among others. To this effect we are productionising some of the concepts while patenting them too.

Were you affected by the pandemic and the lockdowns that followed?

This aspect and the China +1 policy has increased the demand for our solution as customers understand the value it brings to their businesses. We have been leveraging Cloud services since inception and remote working has been a part of our DNA, so the pandemic lockdown has little impact on a day-to-day basis. However, importing of equipment and sourcing from vendors was a challenge due to lockdowns, affecting delivery. To address this concern, we are now planning ahead and procuring inventory in advance while also localising certain critical components.

Are there any expansions to the current facility?

We are planning to double our head count presently and will soon expand our facilities to meet the customer needs. Additionally, we plan to have sales offices in some leading Tier-I cities in India. Also, by 2025 we aim to expand our services across the global markets of the US, the UK, Europe and Southeast Asia in addition to serving the local market.

What were the business sales last year and what numbers do you expect in the coming year?

With the China + 1 policy, we also foresee a significant increase in exports of manufacturing goods. We are on track to achieve a sales turnover that will be 12x of FY21.

Your technology reduces the need for humans on the shopfloor. Is this the way forward?

The goal of Jidoka and manufacturing companies in general, is to improve the quality of products manufactured in India and our solution will help companies achieve that. Our technology is a game changer on the shop floor. It brings about a remarkable transformation in the quality inspection and quality assurance tasks. The quality control personnel are reskilled or upskilled to perform more intellectually stimulating jobs that require critical thinking and decision making to manage and oversee these AI-based solutions and also contribute in refining the defects of the components for inspection. In the long run, this will lead to job-satisfaction and employee retention, thereby benefiting both businesses and manpower.

RELATED ARTICLES

BRANDED CONTENT: 'We aspire to be among the leading sensors and electro-mechanical products manufacturer'

P. Parthasarathy, Founder & Managing Director, Rotary Electronics Pvt Ltd shares the company's commitment and vision to ...

‘Big opportunity for startups lies in products in India’: Detlev Reicheneder

As electrification levels the playing field, the focus on tech and R&D to bring innovative products is the mantra for st...

'I hope my journey makes people say — I can do this too'

Ranjita Ravi, Co-founder of Orxa Energies — the maker of Mantis e-bikes — shares the challenges of building a startup an...

01 Oct 2021

01 Oct 2021

7564 Views

7564 Views

Autocar Pro News Desk

Autocar Pro News Desk