Playing in the bigger league

With efficient management and accountability becoming even stronger parameters for a listed company, Endurance Technologies will have to ensure that every move it makes is well thought out.

After an impressive debut at the bourses, Aurangabad-based two- and three-wheeler component supplier Endurance Technologies charts its future growth strategy around technology, acquisitions and new products.

October 19, 2016 will remain etched in the memory of Anurang Jain (52), managing director of Endurance Technologies. That's the day the bourses welcomed the Rs 1,161 crore IPO of his company. Jain is also fortunate because not too long after, demonetisation struck the Indian economy, and also because he had planned to tap the markets in 2008 but shelved it due to the global economic meltdown. The company IPO, subscribed over 43 times on its final day, has been one of the most successful in recent times. Business activity goes on as usual, but some changes have happened at the top management.

"One of the things we learnt was the importance of ROCE (Return on Capital Employed) or ROE (Return on Equity). We were focusing but not with that much of seriousness, but today when we make our budget or play they are big factors. This kind of focus is coming in," says Jain, in his first comprehensive interview after the stock exchange listing. "I really enjoy the meetings (with investors and analysts) because there's always learning in it," he adds later.

With efficient management and accountability becoming even stronger parameters for a listed company, Endurance Technologies will have to ensure that every move it makes is well thought out. Jain has the broad growth strategy planned. The three key pillars of growth are: collaboration, acquisition and entry into new product segments.

A technical assistance agreement in April with USA's BWI North America for joint development of ABS products for two- and three-wheelers is the first move in the company's strategy of collaboration, after it became a listed entity. This move comes a year before the safety norm of anti-lock brakes for twowheelers (125cc and above) is set to kick in. But Jain is not looking at a 'copy-andpaste' approach in this alliance.

"Our philosophy, from the beginning is, to have technical collaborations but also have our in-house R&D because the roads and driving habits are different in India. Our intention has been to give customers in India based on the conditions which prevail here. If you ask me, that’s a much bigger challenge because ultimately what you talk about is warranties," says Jain.

Adler of Italy and WP of Austria are existing technology partners of Endurance in the areas of transmission and suspension respectively. In a fast-changing, dynamic automotive industry, it won't be surprising to see Endurance Technologies make some moves under the other two pillars of growth. "We are looking for companies which are smaller," says Jain. Endurance Technologies started off its overseas journey with the acquisition of two diecasting facilities in Europe starting in 2006.

The acquisition strategy will continue to play mainly overseas. "Our strategy has been to go for smaller companies (30-40 million euro sales) and then put up greenfield projects to grow these businesses because we have very good relationships now with top OEMs in Europe," says Jain. Fiat and Daimler are among its group of big customers in Europe. Fiat is the second largest, and Daimler the fifth largest customer of Endurance Technologies.

Bajaj Auto, considered the ‘godfather’ of the company, is still the largest customer contributing to 38 percent of overall revenue. Royal Enfield and Honda Motorcycle & Scooter India complete the list of Endurance's top five customers which add up to 75 percent of the company's total business.

With regard to the third growth route of new product segments, Endurance Technologies is looking at opportunities where there are hightechnology futuristic products. "We do not want to do a product which is similar to something which we are doing, or nonautomotive," says Jain.

With the stringent Bharat Stage VI emission norms set to be implemented from April 2020, could emission control systems be a good business segment to venture into? Jain won't say anything beyond, "All that is in our mind."

STRENGTHENING TIES AND BUILDING NEW ONES

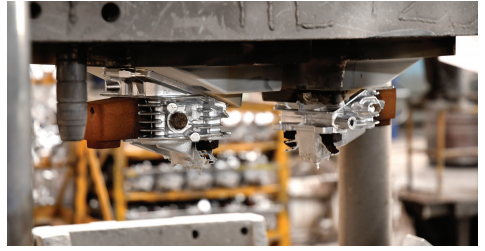

Endurance Technologies is India's largest two- and three-wheeler component supplier. Its target now is to supply products from each of its four divisions (casting, suspension, transmission and brakes) to every customer. Bajaj Auto and Royal Enfield are two customers which source products from all its divisions. As it adds more customers, the scope gets even better. Hero MotoCorp is one such customer.

Endurance became a supplier to Hero for the first time, last year. Jain says the journey with the world's largest two-wheeler maker is progressing well as Endurance has bagged the mandate to be the exclusive supplier of front forks and shock absorbers to Hero's new plant at Halol, Gujarat. Jain says, "They came to us for technology and we are doing our best for them. We are rewarded with this huge business at Halol."

Business from Hero stood at around Rs 75 crore during the last fiscal. Endurance Technologies has recently acquired a 7.4-acre plot at Halol to set up a new plant which will start commercial production during the January-March 2018.

In the highly competitive auto industry, technology is increasingly becoming a key differentiator. Jain and his team have taken note of it. While it holds five patents currently, 46 more have been applied for. A separate 'intellectual property cell' has been formed within the company to track patents in the areas of its business and develop new ones. There is also an elastomer cell and an electronic cell to help strengthen the company's engineering prowess in their respective areas. There's also a dedicated team to do failure analyses of products.

Focus is also on enhancing process efficiency to ensure better quality delivery and reduce warranty costs. Endurance Technologies started its TPM journey in the year 2000, and is continuing. "Customer complaints, early warranty failures and warranty failures, these three can be controlled with a strong process," says Jain.

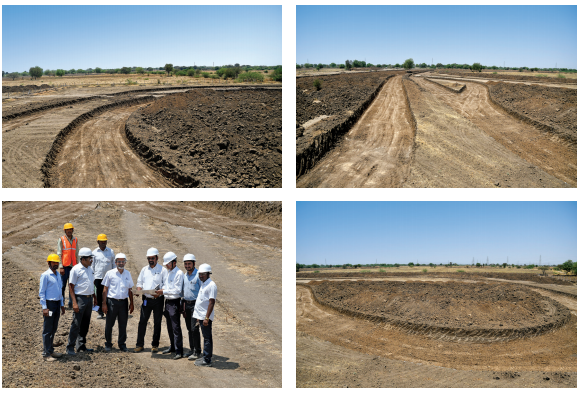

BULDING A TEST TRACK

The biggest bet that Endurance Technologies is making to strengthen its engineering capabilities is by building a test track spread over a 29-acre plot on the outskirts of Aurangabad. The 7-8- kilometre-long test facility with a high-speed stretch of a little over 1km will see an investment of Rs 35-40 crore. This track will serve as a test facility for brakes, suspension and transmission for two- and three-wheelers, and possibly quadricycles too. Its key highlight will be a full-fledged ABS testing track.

Automotive engineering and development services firm Horiba MIRA has been commissioned to design the track, which the company wants to inaugurate in January 2018. "This is our effort towards testing our products on the vehicle and not only on the test rig, towards this first-time-right endeavour." It will also be a key enabler for the Tier I component supplier to transform into a complete solutions provider.

Technology has been identified as a cornerstone for progress at Endurance Technologies. A team of 167 people in R&D has to deliver that. The focus for them is to find the most fitting answer to the question: 'What does a customer want?' Performance improvement, durability, quality, lower cost by way to value engineering, plus, first-time-right products are some key deliverables. Jain is also investing in building a team of right people because only acquiring technology is not enough. As he says, "To be able to absorb the technology, you got to have the people".

The focus on technology seems to be yielding results in the form of a couple of awards that would be the most coveted among all recognitions that the company has received so far. Last month, Endurance Technologies bagged Yamaha Motor Corporation's Global Theoretical Value Production.

The company is one of five awardees globally; 220 suppliers from 14 countries participated in the annual conference. This award was preceded by the 'Grand Award for Quality, Cost, Delivery, Development & Management (QCDDM) Performance 2016-17’ by Honda Motorcycle & Scooter India in February. Jain sees a close link between recognition and business, because an award means that his company is "doing something right".

RATIONALISING PRODUCTION

During our interaction, Jain stressed multiple times on his company's focus on earning "profits with scale". The announcement of a 'voluntary separation scheme' at four of its plants in Chakan, Pune, is a reflection of that approach.

Earlier, the company had shut down one of its two die-cast plants in Pune to lower the breakeven point of operations. On another occasion, a shock absorber, front fork and clutch assembly plant in Chakan was shifted to Aurangabad to rationalise operations. Unlike earlier times, clear projections are difficult to be made by OEMs, because of which suppliers have to design flexible manufacturing operations. "I believe the uncertainties are the new norms in business, so you’ve got to be prepared for that. You’ve got to make yourself financially strong to be able to take these shocks as much as you can. When we say profit with scale, this is one of our strategies in operations," says Jain. Are there more consolidations in the pipeline? "Of course, there are lots of ideas, but we are going step by step," he says.

Leaner production being a key goal, the focus is also on refining the ratio of outsourcing and in-house production. "Doing more business with less plants and with more outsourcing is the model," explains Jain. "We are very careful about whatever affects quality. But things which are, I would say, less important are outsourced. We focus on investments on critical operations, and our suppliers get business. It's a win-win situation.

Especially after the downturn in 2008, we said we must outsource rather than do everything inside," he adds. However, he also adds that there are some components for which the production plan has been reversed. While components and processes like pistons for shock absorbers, casting machining and welding of tubes have been outsourced, production of components like front forks, and brake hoses for disc brake assembly have been shifted to in-house.

Taking a cue from its biggest customer Bajaj Auto, Endurance has also set up a 'vendors association' eight years ago. “We have a very strong vendor association which is there for the last eight years. Like Bajaj Auto, Endurance Technologies is also increasing the number of 'lifetime suppliers'. Highlighting the critical role of a supplier, Jain says, "Today most of the investments are done by suppliers. Without suppliers, the buyer is nothing. A vendor is your partner, so you got to have a strong association. So whatever is the growth in the share, they go as per that."

GROWING OPPORTUNITIES

The upcoming ABS safety norm is a new growth opportunity for Endurance. But before that, it is set to invest on growing its CVT business which it had started in 2001 but slowed down significantly as the initial customers exited the scooter market. The first product with Endurance's CVT was the Bajaj Krystal.

Following its withdrawal from the market, it was supplying CVTs to Mahindra scooters. With the gearless scooter market growing at a good speed, Endurance is expecting some big orders in its kitty. "We have started investing in R&D. We have a CVT testing machine imported from Austria. CVT will be a good upside for us in the future," says Jain.

The market for CVT scooters in India during April-December 2017 grew almost 16 percent compared to only three percent in motorcycles. Jain is betting on scooters not only for CVTs but also for furthering growth of the suspension business vertical as conventional front shock absorbers are getting replaced by front forks.

Overseas business, both from OEMs and aftermarket, is what Jain is also betting on for "profits with scale". The aftermarket business is growing "much faster" than the OEM business both in the domestic and export markets. During April-December 2017, the growth was 21 percent. "The awareness of penny wise pound foolish is coming," says Jain, referring to the growing consciousness about the importance of using genuine spare parts.

Even as business strategies get drawn with the "profits with scale" goal in mind, Jain also shares the values they are built on. At Endurance Technologies, they are customer centricity, integrity, teamwork, transparency and innovation. "I strongly believe in these and they are very important for us going forward. Sometimes integrity/honesty is a difficult path but you cannot go wrong," signs off Jain. Wise words, and message, from someone who has achieved a reported net worth of $1.1 billion. As for the growth of Endurance Technologies, Jain has planned a consolidated annual growth of 8-10 percent.

(This article was first published in the June 1, 2017 print edition of Autocar Professional)

RELATED ARTICLES

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

Qualcomm devises cost-effective ADAS chip for India

The American technology giant is enabling connectivity in modern cars and aims to tap into the price-conscious Indian ma...

27 Oct 2017

27 Oct 2017

15922 Views

15922 Views

Autocar Pro News Desk

Autocar Pro News Desk