NEWS FOCUS: Honeywell develops micro-turbocharger for 800cc diesels as OEMs come calling

If you thought turbocharging was meant only for big-engined vehicles, you couldn’t be more wrong. With fuel prices on the rise consistently, car buyers are increasingly opting for more fuel-efficient models and automakers are doing all they can to deliver additional kilometres for every litre.

If you thought turbocharging was meant only for big-engined vehicles, you couldn’t be more wrong. With fuel prices on the rise consistently, car buyers are increasingly opting for more fuel-efficient models and automakers are doing all they can to deliver additional kilometres for every litre. Until recently, the easy way to obtain higher mileage was to buy a smaller-engined car but with customers seeking both performance and economy, OEMs are turning to turbocharging as a simple, bolt-on way to meet both these needs. Turbocharging becomes important for boosting power as companies downsize engines as it is a cost-effective way to do so. But as space under the hood gets smaller, turbochargers are also reducing in size, which means that they have to be more efficient.

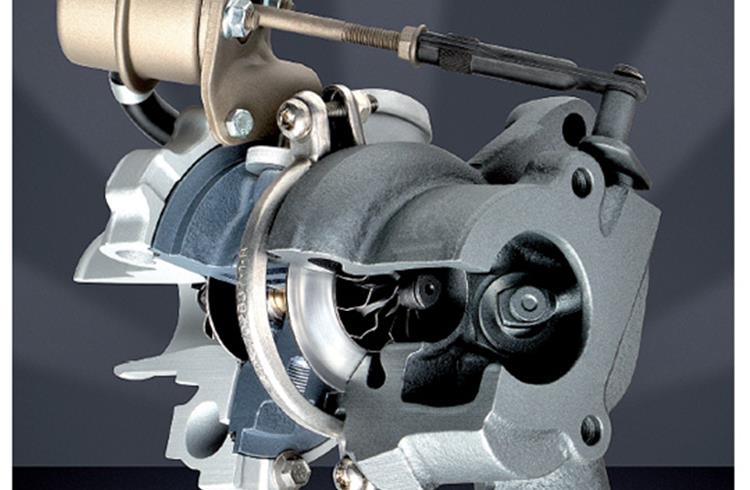

Honeywell Turbo Technologies India (P) Ltd, a business arm of US-based Honeywell, has developed a micro-turbocharger in India. The unit is likely to be fitted in a new two- or three-cylinder 800cc diesel-engined small car slated for launch later this year. Work on the micro-turbocharger involved developing new aerodynamics and bearing systems, and ensuring that oil sealing requirements were met, says David Paja, vice-president and general manager China and India, Honeywell Transportation Systems, in an exclusive interview with Autocar Professional.

|

Given the customer preference for diesel in India as a result of lower operating costs, OEMs are keen to dieselise products in the sub-1000cc engine segment where diesel vehicles are not available. In India’s predominantly small car market which accounts for 80 percent of the total market, the micro-turbocharger business has massive potential. A couple of OEMs in India are believed to be in the planning stages for the development of small, lightweight and compact 800cc diesel engines for their next-generation small cars which will require a small and compact turbo.

Maruti Suzuki plans to roll out a small car powered by an 800cc diesel engine later this year. Another 800cc diesel engine, currently under development, will be fitted on its first LCV (codename Y-9T) which will be among the first products from its new Gujarat plant that will become operational by early 2016. Meanwhile, Tata Motors is working on an 800cc diesel-powered Nano due to debut later this year. Given that Honeywell is a supplier to Tata Motors, it is quite likely that the Nano could well be a candidate for the micro-turbocharger. Honeywell officials, however, would not confirm this.

|

The turbocharging of such engines will become a common feature here as emissions regulations get increasingly stringent. While the Indian market is currently skewed towards diesel, petrol engines will also progressively have to be turbocharged as manufacturers downsize their engines to make them more efficient, say company officials. For Honeywell, the potential for turbocharging passenger cars, LCVs and off-highway vehicles in India is enormous. The company's technologies are expected to find wider application in the future for petrol engines as well as for diesel in terms of the next-generation variable nozzle turbocharger (VNT) diesel technology. VNT tech for diesel is still in a nascent stage in India.

Turbocharging to gain traction in India

At present, the application of turbos in petrol engines in India is miniscule but is expected to gain momentum in the future. Historically, turbocharging has been a predominantly European feature as a result of the number of diesel cars that operate there. But two game-changers for Honeywell are trends in the US and Chinese markets, which are petrol-driven, says Nitin S Kulkarni, vice-president, customer management, Honeywell Turbo Technologies.

In China, regulations in force that mandate OEMs to increase their fuel efficiency by 40 percent by 2020 are the catalyst for engine downsizing and turbocharging. Global trends have indicated movement towards petrol turbocharging and the next-generation VNT technology in diesel.

Here Honeywell’s latest-generation VNT delivers transient response, low-speed efficiency, reliability, weight savings and packaging flexibility. VNT technology, in a mono-turbo set-up, is suited for diesel engines ranging from 0.9 litre to 3.0 litres. While the majority of VNT applications are in the 1.4- to 2-litre range, the architecture is also heavily specified in the premium 3.0-litre V6 diesel segment.

The key aspects in a VNT turbo are the exhaust flow through the turbine wheel that is controlled by a row of vanes that move to match the exact boost requirements of the engine. At low engine speeds, the variable nozzle turbine vanes close to restrict the exhaust air flow through the turbine, thus increasing turbine power and boosting pressure. At higher engine speeds, the moveable vanes open to maximise the exhaust gas flow, thereby avoiding turbo over-speed and maintaining the boost pressure required by the engine. The current Honeywell VNT turbos are upgraded versions of the third-generation VNT launched in 2004.

The key advance is the way variable mechanisms were attached onto the bearing housing through an elastic shroud. This new platform has delivered many innovations – a new cartridge design, new cambered vanes, a new generation turbine wheel, improved aerodynamics and better controllability.

Honeywell’s third-generation VNT Turbo contributes to higher torque levels, particularly at low-engine speeds and helps deliver more power across a wider range, better acceleration through improved transient response and cleaner combustion. Lower emissions are made possible by exhaust gas recirculation (EGR) facilitated by the turbo. VNT technology is also a key enabler of engine-downsizing, an industry-wide trend towards the creation of smaller, more fuel-efficient and lower-emission powertrains. Honeywell makes turbos compliant with Euro 5 and 6 emission norms for US and European applications. “This technology will come to India as emissions regulations go to BS V and VI. We already have the VNT on one application in India but future applications in diesel will have more VNT technology. We already make VNT turbos at our Pune plant which is equipped for VNT technology,’ says MilindGodbole, managing director, Honeywell Turbo Technologies India. He adds that the company’s Pune plant exports VNT turbos to Europe to meet Euro 6 applications. “When VNT tech comes to India, we have the capability already developed,” says Godbole. Honeywell provides VNT turbos for the Safari Storme.

More power to the Honda Amaze

Honeywell is also a key supplier of turbochargers for the Honda Amaze saloon launched earlier this year. Turbo development is now looked upon by OEMs as a key part of their overall engine strategy with the turbo considered an integrated part of the development process. “Typically, turbo application work lasts anywhere between 12-24 months, depending on the complexity of the project. The Amaze programme fell within this range,” says Paja. But Honeywell officials say that supplies for the Amaze will depend on demand. The development of the Amaze was unique in that it involved innovating a best-in-class fuel-efficient vehicle for India. Honeywell worked closely with Honda and one innovative solution leveraged by the carmaker involved the use of low-viscosity oil. Honeywell facilitated its usage by providing matching solutions at the turbocharger level that enabled Honda to set a new benchmark in the Indian market. “We believe the launch of a diesel engine by Honda has set a trend in terms of what is coming into the market in the next few years as OEs launch new models of turbocharged vehicles. About 45 percent of vehicles sold in India have turbochargers as compared to Europe where 75 percent are turbocharged,” says Paja.

India as a CoE

For Honeywell, India is a global centre of excellence (CoE) for development of these technologies. Engineering work for the Amaze's turbo was the result of collaboration between Honeywell’s engineering teams at its engineering centres in Bangalore and Pune along with the engineering teams in Japan and Europe. One of the development areas for the Bangalore CoE is developing small diesel turbos for the world market. Over 6,000 engineers work at Honeywell's centres for technology development at Hyderabad, Madurai and Bangalore. The company plans to turbocharge 10 new vehicles each year.

Godbole feels that if a certain level of performance has to be achieved in a vehicle, a turbo can be used on a much smaller engine – typically 30 percent smaller – for enabling fuel economies. “If you want to achieve the same level of performance of the 98.6bhp 1.5-litre diesel Amaze without a turbo, one needs a two-litre engine. In reality, turbo increases fuel economy by reducing engine size." On the Amaze, the turbo has matched the engine's performance requirements resulting in minimal turbo lag that enables seamless driving. Honeywell is already a supplier to many OEMs for both BS III and BS IV applications in the country including GM India, Honda Cars India, Volkswagen India besides Maruti Suzuki and John Deere (for their export programmes) as well as Ashok Leyland.

Honeywell has also collaborated with General Motors for its recently launched Chevrolet Enjoy MPV with the turbo based on the same platform as the one for the Amaze, although the engine size is smaller in the 102.5bhp 1.4-litre Enjoy. In India, within the light vehicle category, turbo penetration has grown from 27 percent in 2010 to over 45 percent in 2012. With close collaboration with Honeywell Aerospace, Honeywell Turbo Technologies plans to continue to pursue technologies and innovations that improve both turbo and engine efficiency in the areas of aerodynamics, material composition, bearing systems and packaging.

In India, Honeywell harnesses wastegate turbo technology that can be be used for both diesel and petrol applications. Its DualBoost technology – a new concept for petrol turbocharging that significantly improves ‘time-to-torque’ while delivering impressive steady-state performance is expected to be a key contributor to future improvements. DualBoost employs an axial turbine more commonly found in aerospace applications, and couples it with a dual-sided compressor. Overall, going forward Honeywell's turbochargers have a long and important innings to play in India as manufacturers pare down engine sizes and also cater to customer demand for both higher power and improved fuel efficiency.

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

By Autocar Pro News Desk

By Autocar Pro News Desk

19 Jun 2013

19 Jun 2013

18062 Views

18062 Views