Innovative engineering takes shape in Mysore

Intent Design develops Rapid Braking System, which can be manufactured at one-fifth the cost of conventional ABS. There's also NERV regenerative vehicle tech engineered for stop-and-go traffic in emerging markets. Jaishankar Jayaramiah reports.

Intent Design develops Rapid Braking System, which can be manufactured at one-fifth the cost of conventional ABS. There's also NERV regenerative vehicle tech engineered for stop-and-go traffic in emerging markets. Jaishankar Jayaramiah reports.

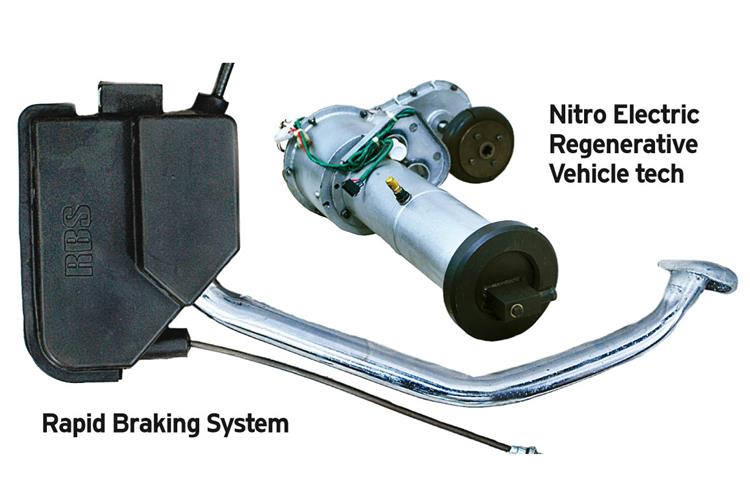

The US-headquartered Intent Design has been inventing several products for the Indian and overseas auto industry at its Mysore Research & Development Centre. It recently launched two new products and expects to sign licensing deals in the two- and three-wheeler segments soon. These are the Rapid Braking System (RBS) and Nitro Electric Regenerative Vehicle (NERV) for the two-wheeler and three-wheeler segments respectively. In addition, the company has to its credit several patents for its automotive products.

Any new automotive product, which offers gains – either technological or economical or both – will always attract OEM attention. Heading in this direction, Intent Design has been driving its products through its Indian R&D centre. The company is the brainchild of Karnataka-based Srinivas Bidare, who has a double masters in engineering and worked for 30 years in North America and Europe (including eight years with Johnson Controls) and was a consultant to several American companies.

In an exclusive interaction with Autocar Professional, Bidare, who is president of Intent Design, says the company was set up in 2006 in Michigan, US, as a product solutions company providing intellectual property development and total systems solutions, to cater to not only to the automotive sector but the aerospace and consumer product sectors too.

He says, “We are developing products for OEMs and Tier 1 players from our US operations for North American companies in various sectors including automotive. Our customers include the Big Three – GM, Ford and Chrysler.”

LICENSE TO GROW

Now by inventing new products through its Indian R&D Centre in Mysore which was set up five years ago, the company intends to identify interested OEMs and Tier 1 companies so that it can license its new products on a royalty basis.

In addition to its local R &D operations, the firm also has a tool design and development centre in Bangalore that primarily develops moulds for plastic auto components. The Bangalore centre has already developed designs for more than 150 tools for Canada-based tool maker Active Burgess, which is also a stakeholder in Intent’s US operations.

With the earnings from Intent’s US and Bangalore operations put together, the company is able to fund its research activities at the Mysore R&D centre, adds Bidare.

HOW RAPID BRAKING SYSTEM WORKS According to Bidare, the Rapid Braking System or RBS has been developed as an alternative to the popular anti-lock braking system or ABS. It is an innovative technology for two-wheelers that enables fast and stable deceleration of vehicle at high speeds, specifically during ‘panic’ braking. This technology has been designed keeping in mind the need for a cost-effective solution that can offer safety to riders, he claims.

Its key features include simultaneous braking of the front and rear wheels, automatic compensation for brake differential wear, a fail-safe mechanism to isolate front brake cable failure, real-time braking force regulation and redistribution between front and rear, and hand lever and footbrake combined with regulation and redistribution. "It is ready for production and can go to market within 90 days," details Bidare.

Intent Design’s RBS has already been fitted onto 50 motorcycles across Karnataka. Over a year, the company claims that riders’ feedback indicates that it is successful. Since no regulatory permission is required for the aftermarket in private vehicles, Intent was able to fit this product onto these bikes.

Now a reputed Swedish component maker has approached Intent Design, showing interest in RBS. Intent has agreed to permit the Swedish Tier 1 company to make trial launches of RBS in four cities in India. "If RBS clicks,"says Bidare, "then Intent plans to license it to the Swedish firm on a royalty basis." Meanwhile, another Indian two-wheeler maker is also evaluating RBS for fitment in its vehicles produced locally.

NERV FOR EMERGING MARKETS

With regard to its other invention – Nitro Electric Regenerative Vehicle (NERV) – Bidare says this is a regenerative vehicle technology specifically engineered for emerging markets such as India, China and other South East Asian countries where stop-and-go scenario is a norm in traffic.

The NERV system recovers the vehicle’s energy that gets wasted during braking and stores it in the form of compressed fluid. It is then used to propel the vehicle, reducing fuel consumption in stop-and-go situations. The company claims that it boosts mileage by 10 to 40 percent. "The NERV uses displacement recovery method whereas all other technologies leverage speed-based recovery methods," says Bidare.

Intent Design has also tried to market NERV locally but could not commercialise it as there is no proper authority that has to be approached for approval. NERV can ideally be used in autorickshaws, which fall under the commercial category. Now a Chinese three-wheeler maker has approached the Mysore-based company for NERV and Intent Design is exploring the opportunity of licensing this product to the Chinese company on a royalty basis.

In India, Intent has developed over 100 products for companies that operate in multiple sectors. Of this, it made eight products for four customers from the automotive sector. As they have signed non-disclosure agreements with Intent Design, Bidare does not reveal their names.

In addition to the automotive segment, the company is also taking up R&D projects in the aerospace, defence, consumer goods, medical, hydro-mechanical design, toys, agriculture and sporting goods sectors.

With the Indian automobile sector eager to enhance efficiency of its products but in an economical manner, Intent Design has a good opportunity to tap this demand for its own growth as well as contribute to

the technology evolution in India.

INTERVIEW WITH SRINIVAS BIDARE, PRESIDENT, INTENT DESIGN

Of the various sectors that Intent is present in, what is the contribution from the automotive segment?

I got my first patent in India at 19 for an ABS. With the company having over 20 patents and 50-plus intellectual property disclosures, our local and global teams are working together to deliver world-class product engineering design consulting services to OEMs and suppliers.

We offer automotive, mechanical engineering design services as well as electrical engineering services for fully-integrated automotive design and manufacturing processes. In addition, we have extensive experience delivering complex technology-driven solutions in worldwide automotive manufacturing systems applications, including instrument panels, seating systems, trim, instrument panel, HVAC systems and consoles.

Is the RBS an alternative to ABS and how does it function?

The RBS is a patented technology that has been invented to meet the specific needs of varying road conditions. It has a unique system that, unlike combo brakes, does not apply fixed braking to both wheels. Instead, it varies the braking force front to rear depending upon the need. Since it has no hydraulics or electronics, it is reliable and maintenance-free. RBS has the ability to change the braking force ratio between the front and the rear wheels. It can be manufactured at one-fifth the cost of ABS.

Has this technology been tested?

The RBS has undergone rigorous testing of over 1.5 million braking events without failure on the test rig as well as in road testing on both urban and rural roads. There are no permanent modifications to the bike and no change in brake shoe, brake drum, hand brake lever or foot pedal location.

What is fitted is a distributor (part of the RBS pedal system) that ensures, regardless of whether the hand lever is actuated or the pedal is pressed, the needed amount of brake ratio split is maintained in real time as the vehicle operates. The whole process can be reversed within 15 minutes to take it back to its original condition if so desired.

Has this system certified by ARAI?

In India currently the aftermarket segment is unregulated. There are no legal requirements for aftermarket products. ARAI can only certify only OEM bikes to existing Indian standards. As such, ARAI is not authorised and will not certify an aftermarket product. Anyone can install this product but we recommend it be installed by an Intent Design-trained professional. This is a product that has implications for safety and hence has to be taken seriously.

What are the salient features of NERV or Nitro Electric Regenerative Vehicle?

The NERV is 100 percent recyclable unlike regular battery technology. It has no life-limiting components that need to be discarded after certain years. This device can last the entire lifetime of a vehicle. There are no precious metals, rare minerals, toxic fumes or gases. It has very high efficiency due to direct drive technology. It reduces the wear-and-tear on brakes, increases starting torque by almost 50 percent and reduces emissions. It is an electro-mechanical device that is controlled via an electronic device. This device is a microprocessor-based unit that regulates the braking and acceleration of the vehicle based on driver demand.

Can NERV be used on any automobile from a two-wheeler to a bus?

This technology is scalable, independent of fuel, front wheel and rear wheel. It is currently fitted into an autorickshaw for three-wheeler demonstrations, a one-tonne commercial truck and an SUV for four-wheeler demonstrations.

Can you tell us about the products you have developed for foreign OEMs?

For US-based companies, Intent Design has developed around 50 products, of which 20 products were for OEMs and Tier 1 companies in the US auto industry. To name a few, the company has developed the Power Fold and Tumble seating system for a US-based OEM as well as a tailgate step for a pickup truck maker in North America.

Do you expect support from the government?

The Indian government should encourage new inventions that are targeted at the automotive segment. It should have a proper regulatory mechanism to approve such products in order that they can be commercialised by OEM and Tier 1s. This kind of encouragement will expand activities in the Indian automotive R&D sector.

RELATED ARTICLES

BRANDED CONTENT: Eliminating the worries of battery charging with smart solutions

The charging infrastructure is the backbone of electric mobility but is also one of the key perceived barriers to EV ado...

The battery-powered disruptor

Greenfuel Energy Solutions is planning to shake up the EV battery market with the launch of a portfolio of specially eng...

SPR Engenious drives diversification at Shriram Pistons & Rings

The engine component maker is now expanding its business with the manufacturing of motors and controllers through its wh...

02 Sep 2014

02 Sep 2014

8849 Views

8849 Views

Autocar Pro News Desk

Autocar Pro News Desk