Altigreen sends a hybrid message in a retrofit kit

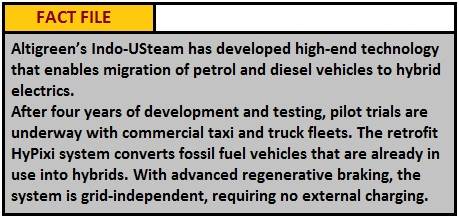

Bangalore-based start-up Altigreen Propulsion Labs has developed HyPixi, a hybrid electric retrofit kit targeted at taxi and light commercial vehicle fleets.

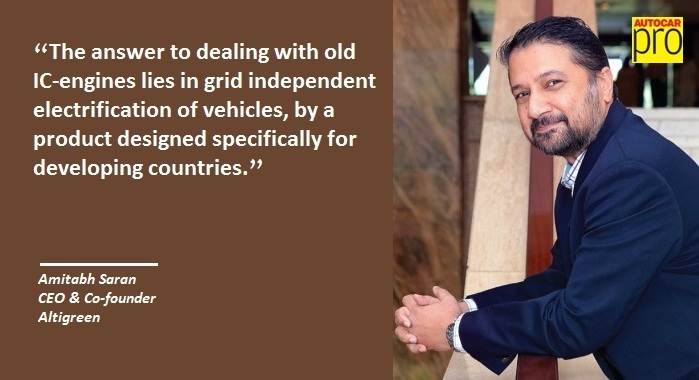

Electric cars may not be the complete answer for curbing environmental pollution in developing countries. That’s what Amitabh Saran, co-founder of Bangalore-based, start-up company Altigreen Propulsion Labs, seems to think.

So the company is gunning for a commercial push to its low-cost retrofit system – HyPixi – that converts fossil-fuel based vehicles into hybrid electrics. The company claims HyPixi also improves mileage by over 20 percent while cutting tailpipe emissions by 20 percent in both petrol and diesel-engined vehicles.

Interestingly, the idea for the kit germinated in 2010 when the hybrid Toyota Prius was launched in India at Rs 32 lakh. The green car was a trigger for developing a low-cost hybrid solution for the mass market segment. Passionate about cars and the environment, Amitabh Saran, CEO and one of the four co-founders of Altigreen, feels that countries like India where 81 percent of the electricity is generated from coal or heat may not make electric cars green as they lead to higher emissions from EVs compared to petrol or diesel cars.

“We also need to deal with a large ageing population of existing vehicles with old internal combustion engine technology. The answer lies in grid-independent electrification of in-use vehicles, by a product designed specifically for the needs of the developing countries,” he told Autocar Professional in an exclusive interaction.

Developed in India, for developing countries, the retrofit system is priced between Rs 60,000-Rs 100,000 and is aimed at driving fuel savings for taxi and light commercial vehicle fleets. Altigreen has tied up with financing institutions to offer easy finance. According to Saran, taxis that run 200-300km daily will recover the cost in a year.

Hassle-free retro fitment

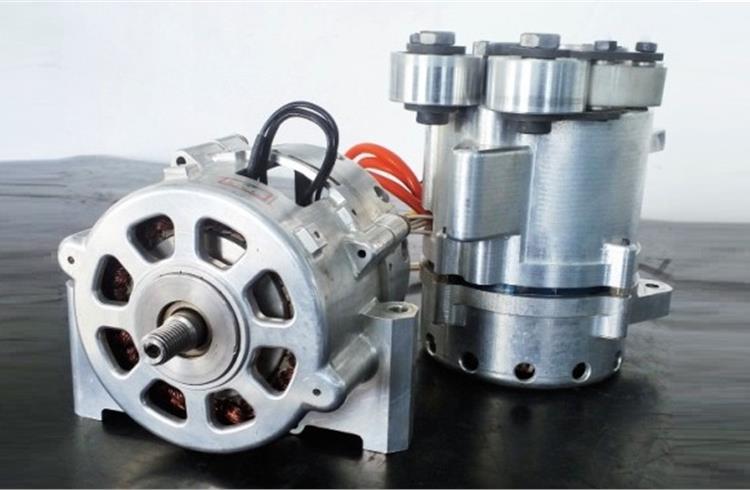

HyPixi can be installed in four hours by a couple of technicians at specific multi-brand outlets that Altigreen is tying up with. Initially four outlets will be set up in Bangalore and a similar number in Delhi. HyPixi works on a torque-assist regeneration electric system. The motor-generator is equipped with a small form factor that enables easy retro-fitment. No changes are needed to be made in the existing ECU or combustion engine for fitting the HyPixi.

So how did it all start? Saran, a PhD in computer science, has been working in the software domain for the past 15 years after which he decided to strike out on his own. He partnered with others such as Lasse Moklegaard in the US, who had 17 years’ experience in engine control on Ford, Mack Trucks, John Deere and Cessna, Lear jets as well as US army vehicles. Lasse worked on the driving data of various Indian cities and created mobile apps. While working on the software models, he arrived at the conclusion that this data was conducive to hybrid applications, which led to the four-member team exploring that angle.

The other co-founders include Shalendra Gupta, who has 27 years’ finance, business development and manufacturing experience, and John Bangura, who has spent two decades working with high-performance motors and electronics for aerospace, military and hybrid vehicles.

Together, they were able to create a machine that was small yet powerful enough to run a car. “We created a proof of concept car in the US in 2012 and ran it for three months in the suburbs of Iowa. It had a big motor, a typical 8 KW machine, 2 feet in length and weighing 60kg. That gave us the confidence that we were getting into something that made a lot of sense and we should use it as a retrofit instead of trying to create our own vehicle,” elaborates Saran.

In January 2013, the start-up company was founded with a seed capital of Rs 20 crore and the team moved forward to create IP patents in India, filing them in India and in the US. It helped to have Chetan Maini, the former CTO of Reva Electric, as investor and board member to guide them technically.

The founders were keen to develop an ecosystem of people who would be interested in building prototypes for them in India. IP was a key to ensure it was not replicated easily. Thus the kit was divided into a number of sub-components, not just at the machine level like a motor or generator but even in terms of sub-components. Thereafter, the co-founders began approaching manufacturers who were experts in various electric component domains.

The kit, which comprises eight parts, is assembled at Altigreen's Bangalore facility-cum-laboratory. Importantly, the retrofit kit does not require any external charging and uses a low-cost, lead acid battery pack. The kit does not impinge on the engine’s effectiveness and can be adapted for use in buses and trucks as well.

Successfully tested

Incidentally, HyPixi has been successfully tested on around 12 petrol and diesel cars as well as small trucks. Also, it has received regulatory clearances and certification. Some customer pilots are underway with Carzonrent, online hypermarkets UrDoorstep and BigBasket and the ePorter.

The start-up foresees large commercial potential for HyPixi which it plans to launch this month. It hopes to cash in on a target market of 50 million vehicles in India over the next 10 years. In the first phase of its launch, fleets of taxis, pick-ups and small trucks, pegged at two million units, will be addressed. Phase II of the rollout will see about 10 million personal cars being the key target. Later, larger multi-axle vehicles will also be considered.

ASEAN, South American and African markets also throw up a market potential of another 200 million vehicles.

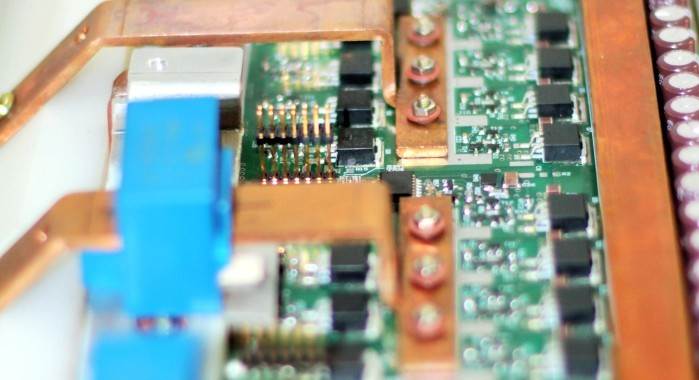

Proprietary power electronics and hybrid controller.

The HyPixi can be adapted to various engine types and emission norms. Altigreen has worked closely with the Automotive Research Association of India (ARAI) and the government of India to put in place standards to drive hybridisation. The standards have been notified as part of the Central Motor Vehicles Rules and have been communicated to the RTOs in 2015 to act as a guideline to manufacturers. The standards also specify the list of tests to be taken up by various agencies post which a certificate will be awarded to the kit manufacturer. While each of the components have to pass through 70-80 rigorous tests matching international standards, the kitted vehicle has to pass tests on various parameters conducted by ARAI.

In January 2015, Altigreen underwent the first development test at ARAI on a small truck. The following year, the company received type approval and certification from ARAI. The challenge now being addressed, along with the government, relates to kitting various models of vehicles. Current standards stipulate that each model of every vehicle be certified.

This is a daunting and time-consuming exercise which takes 8-10 weeks, apart from being expensive. “If you add model years and emission norms, you are talking about a huge spectrum of cars. So we are working with the government on ways to simplify certification if the engine technology is not changed,” says Saran.

A silver lining in the cloud is that Altigreen has successfully completed the certification at ARAI, ICAT and at VRDE. The trial runs in Bangalore have been able to achieve 9km per hour through regenerative braking.

The first commercial launch is planned using Maruti Dzire sedans with fleet operators. The most used vehicles for delivery models have been identified as the Toyota Etios petrol, Tata Indigo diesel as well as smaller diesel trucks such as the Tata Ace.

Thus far, certification has been received for the Maruti Dzire diesel, while the petrol-engined Toyota Etios has been certified but documents are awaited. The start-up’s focus is on diesel as it is considered more polluting than petrol.

Altigreen is bullish that once HyPixi hits volumes, the cost of the kits will commensurately reduce. It is mulling production of 3,000-5,000 kits per month with electrical parts to be manufactured by various suppliers across India. Also in the pipeline is a more cost-effective kit which is touted to be more efficient and meant for casual city driving for a 30-40km stretch daily. This kit is currently under development in Bangalore.

After consolidating in the domestic market, Altigreen plans to explore partners to market HyPixi globally over the next five years.

This feature was first published in Autocar Professional's 12th Anniversary issue. Subscribe to our magazine to get exclusive news, features and analysis.

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Shobha Mathur

By Shobha Mathur

06 Jan 2017

06 Jan 2017

29899 Views

29899 Views