Acey gears up for plants in Chakan, Uttaranchal

The new facilities will meet the needs of Tata Motors, M&M and Bajaj.

Acey, which is based in Bilimora (Gujarat), will kick off trial production next month. Regular supplies will begin in April, said Mayank A Choksi, managing director in an exclusive interview. “Entering Uttaranchal will also help us access northern markets,” he added.

The company has earmarked Rs 5 crore across three phases for the Uttaranchal project. The first phase will involve Rs 3 crore and targeted solely at the Tata Ace. The balance will be spent equally for M&M and Bajaj. Acey is a single source supplier for almost the entire commercial vehicle range of Tata Motors. About 55 people will be working in the first phase which will see daily production of about 10,000 light and 2,400 heavy control cables.

By the end of the third phase, the Uttaranchal facility will churn out 24,000 heavy and 12,000 light cables daily. Choksi said the number of people working here would be up to least 180 by that time. As for Chakan, the company leased a shed as an interim arrangement so that production could begin last December and supplies assured to Bajaj Auto’s Discover and Pulsar bikes. The new plant will involve an investment of Rs 1.5 crore and will cater to Bajaj’s two and three-wheelers.

For the record, Acey is already a single source supplier for all the cables of 112cc Discover and three-wheelers and for two cables in the case of the Pulsar and 125cc Discover DTS-i. Both the Uttaranchal and Chakan plants will have two shifts each and follow the single piece flow concept in contrast to batch production done at Billimora. Once they are up and running, the company hopes to more than double its turnover to Rs 80 crore by the end of next fiscal.

Acey has working hard on continuous improvement and this has seen rejection levels drop sharply from about 250 ppm four years ago to 80 ppm. In the case of Bajaj, it has maintained zero ppm for a large part of this fiscal. Apart from the domestic market (where its other customers include Force Motors, Greaves and Kinetic), the 26-year-old company has also been exporting its products to Iran, Sri Lanka and parts of South America and Africa. Merchant exporters help out in the case of exports to the European Union and US.

Recently it exported a pilot batch of a particular tachometer cable comprising 1,500 pieces to a company in the Netherlands that makes agriculture machinery. It also kicked off exports to a farm equipment maker in the same country. The share of global business could improve with the commissioning of the two new plants. Choksi said that Acey would also focus more aggressively on the domestic aftermarket where its share is little to write home about right now. As part of this endeavour, it will soon appoint distributors in a phased manner.

There are two associate companies – Acey Engineering India and MAC Engineers - .which individually make cables for bicycles and speedometer cables for Bajaj Auto. They also help out Acey with wire ropes, strands and turned parts. The company manufactures almost all its parts inhouse. Of the 230 plus required in making cables, it makes more than 180 components and this helps reduce lead time in new product development. Choksi says that Acey develops new products in less than two weeks as against the industry average of 4-5 weeks.

Despite the fact that its Gujarat plant is located in a remote area, the company does not maintain any inventory of finished products. Whatever produced during the day is despatched to its arehouses in Chakan and Waluj the same evening. It maintains two days of stock at its warehouses and supplies to customers on a JIT basis. Apart from efforts to reduce cost and eliminate waste, Acey is also working on reducing raw material inventory to seven days from the present level of 10. About a year ago, this was 28 days!

RELATED ARTICLES

Royal Enfield offers Rentals and Tours service in 25 countries

The RE Rentals and Tours service covers everything from motorcycle rentals and professionally guided tours to assistance...

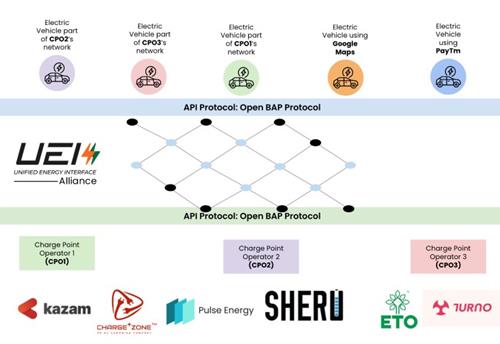

Charging network operators, energy companies partner to create UPI-like network for EV charging

The Alliance includes member companies like ChargeZone, Pulse Energy, Kazam, Sheru, Trinity, Turbo, etc.

InnerCircle: 'Consumers are willing to wait for innovative EV products; tech suppliers must lower entry barriers', says Nilesh Bajaj, CEO at Vayve Mobility

The company says the waitlist for its maiden two-seater electric car, Vayve Eva, clearly determines its potential demand...

By Autocar Pro News Desk

By Autocar Pro News Desk

23 Feb 2007

23 Feb 2007

5415 Views

5415 Views