Meritor holds first roadshow in India

Meritor’s first roadshow in India takes its brand proposition of superior performance directly to end-users. In trucktown Namakkal the company explains to operators the advantages of its most significant new product so far. By Eliot Lobo.

Rather than be held hostage any longer to the OEMs’ whims, the company recently decided the only way it could generate a pull for this potential game-changer would be to have operators demand it in their trucks. For that, it would have to educate them in the benefits of running in “dual mode”, as Meritor HVS India vice-president S Raghunathan describes it.

The company had been looking for opportunities to connect with end-users for some time, and the best place to begin, it was clear, was Namakkal, whose enterprising populace seems to have trucking in its genes. The operators here are extremely savvy about the specifications of their trucks, well organised, and – crucially – far ahead in thinking than the OEMs themselves.

The small Tamil Nadu town is headquarters to three of the most influential trucker associations in South India — the Namakkal Taluk Lorry Owners Association (NTLOA), the Southern Region Bulk LPG Transport Owners Association, and the Namakkal Taluk Trailer Owners Association, which together count more than 9,000 members.

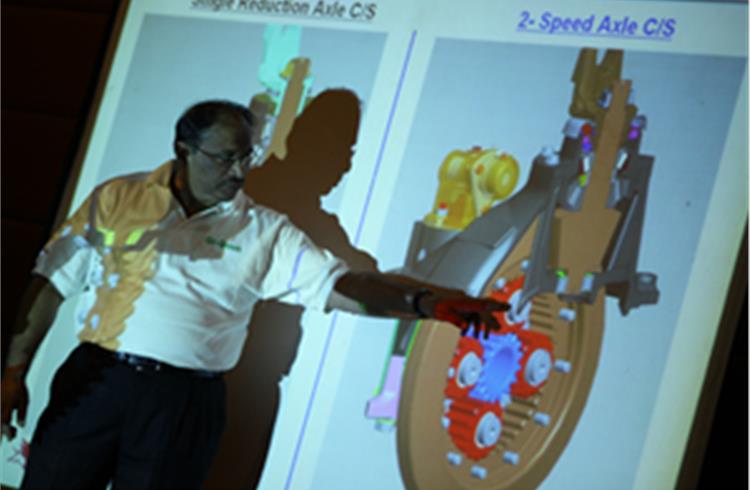

Meritor’s first-ever user event last fortnight followed a week of assiduous planning, and was attended by 920 truckowners in all. Over three sessions, Raghunathan and Ramesh Kulkarni, programme manager for the two-speed axle, made presentations on the MS 13-245 first to the board members of NTLOA and their associates, and then members of each of the other two associations.

Kulkarni explained to the invitees that the single-reduction axle ratios in their trucks were designed for gradeability and not for fuel economy. In a largely commoditised market, the OEMs offer less than a handful of ratios, typically close to 1:6 or deeper, selected for the “worst case”, or the steepest gradient, the truck is likely to encounter.

But because of the wide variety of terrains that characterise the Indian landscape, the truck is revving harder than it should for a given road speed on level stretches, which make up as much as 70 percent of the average route profile in actual operation.

With the MS 13-245, running a faster primary ratio of 4.3 (the company will later offer an even faster 3.23), fuel consumption has been reduced by “at least” 7 percent in Ashok Leyland 6×2 trucks operated by three fleetowners that have had the axle on trial for a couple of years.

The audiences were shown letters of endorsement from VRL, India’s largest fleetowner, and two of Meritor’s own transport providers. Over a run of 9,000 km with the two-speed axle, VRL claims the fuel efficiency of its 2518H improved from 3.86 km/l to 4.07 and the average speed rose from 35 km/h to 40–45 km/h.

Ravindra Transport Service, which runs from Pune to Mysore, said it saved almost 20 litres of diesel on every trip, and Friendly Logistics provided a mileage calculation that showed an improvement of by 7.2 percent. While the infrastructure across the country continues to improve, trucks will encounter a patchwork of road conditions — both very good, smooth roads, and also the roughest surfaces. “The two-speed axle is suitable for both, the worst conditions as well as the best,” Kulkarni told his absorbed audience. “If the driver sees a better road and feels he can go faster, he just needs to activate the faster ratio.”

One of the NTLOA members, S P Ramaswami, who owns a fleet of 15 of Ashok Leyland’s 2214 model that run on the Kumbakonam-to-Gujarat route, claimed he had achieved a fuel efficiency figure of 5.1 km/l on two of his trucks he’d fitted with tubeless tyres, and asked to have his trucks retrofitted with the two-speed axle immediately if they would help him gain an additional 0.3 km/l! As an aside to this correspondent, Automotive Axles director Ashok Rao reckoned that Ramaswami could possibly achieve 6 km/l with the two-speed axle, but reserved any claim till the Meritor team had studied the specification and condition of the trucks and the actual requirements of the application. Kulkarni also presented a journey time and fuel consumption calculation for the 2,200km Bangalore–Delhi trip based on the performance data of a standard 6×2 line-haul truck with single-reduction axle mapped to test results from the VRL trial vehicle and the OEMs themselves. The data were then extrapolated for a vehicle running the Bangalore–Delhi route with the help of VRL’s travel logs.

Depending on the terrain, load, and how skilfully the driver is able to use the faster speed, the axle provided a minimum 7 percent improvement in fuel economy, Kulkarni pointed out. “The calculation was based on the minimum fuel economy improvement achieved on a regular haulage vehicle. Although the highest fuel economy achieved is more than 11 percent, we considered the lowest number for a calculation of the benefits,” he said.

The final result? A saving of 22 hours and Rs 1,700 per trip!

As significant as the fuel efficiency gains, Raghunathan pointed out that the planetary gearset built into the crown wheel improves its rigidity, making it more resistant to abuse than the similarly-dimensioned crown wheel of Meritor’s own 1495 single-reduction axle common in 6×2 and 8×2 applications. A big benefit that would certainly interest the most overload-obsessed of Indian transport operators.

ELIOT LOBO

RELATED ARTICLES

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

Maruti Suzuki expands capacity at Manesar plant by additional 100,000 units

New assembly line at Plant A expands total manufacturing capacity at the Manesar plants to 900,000 units per annum. Alon...

By Autocar Pro News Desk

By Autocar Pro News Desk

29 Feb 2012

29 Feb 2012

4190 Views

4190 Views