Maruti Suzuki saves over 8.3 lakh tonnes of CO2 over a decade

Apart from benefiting from improved efficiencies in its petrol and diesel vehicles as also with use of the Heartect platform, the carmaker has sharply cut down on water usage at its plants and workshops.

Making an announcement on World Environment Day, Maruti Suzuki India says that, over the past decade, its innovations across products and manufacturing processes that contain emission and lower water use, as also CNG, LPG and smart hybrid vehicles, have saved an estimated over 8.3 lakh tonnes of CO2 emissions.

The country’s leading carmaker says it has been consistently achieving improvements in fuel efficiency in its conventional petrol engine and diesel engine vehicles. These efforts, through focused innovations such as new-generation platforms, friction reduction in drive train and improvement in drive-line losses, have led to nearly 20 percent fuel efficiency improvement in both petrol- and diesel-engined compact cars.

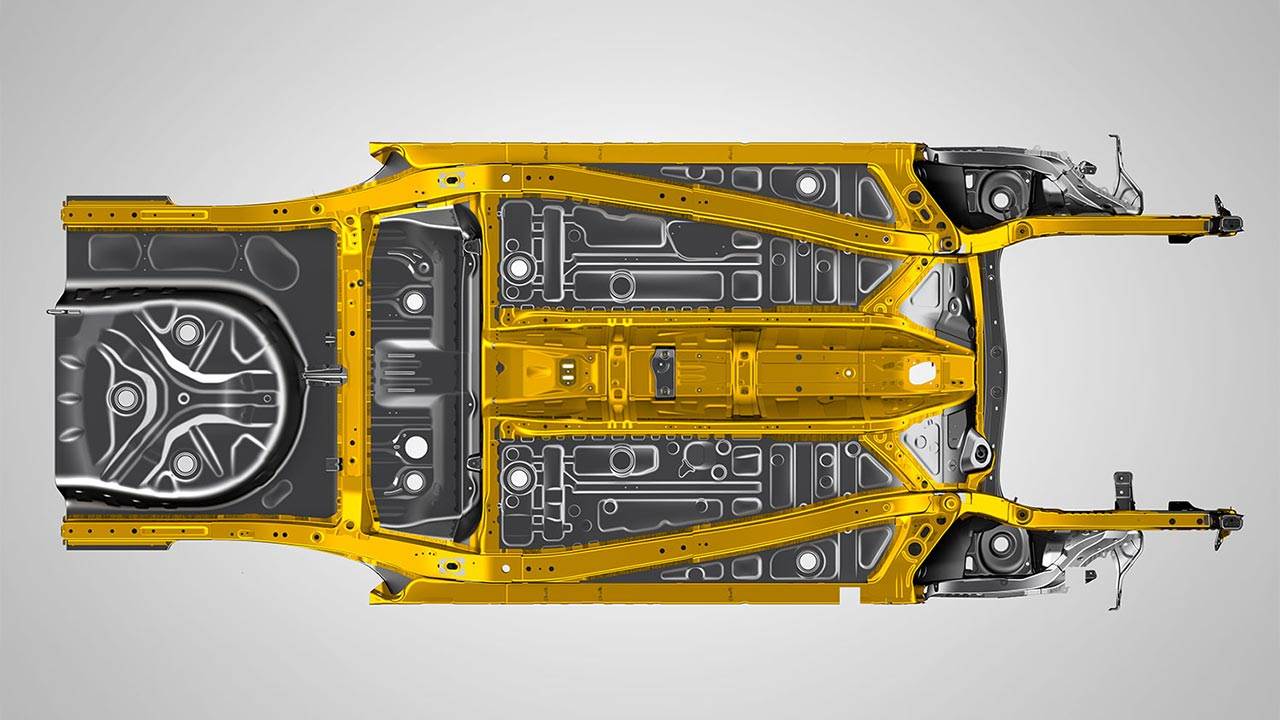

The next-generation Heartect platform (pictured above), used in the Baleno, Ignis, Swift and Dzire, lowers CO2 emission by 6-8 percent while also offering superior performance and safety.

Reducing water usage to the max

At its manufacturing facilities, Maruti Suzuki has reduced water consumption per vehicle manufactured by 6 percent in 2017-18, compared to the previous year. At the same time, there is a 1 percent reduction in CO2 emission while manufacturing every vehicle over the past year.

By using its Dry Wash system at its service workshops to clean nearly 3 million vehicles, Maruti Suzuki says it has saved a whopping 285 million litres water in FY2018. The environment-friendly Dry Wash system helps conserve water, shortens wash time and improves final wash quality. At present, 588 Maruti Suzuki workshops across 186 cities use the Dry Wash system.

Commenting on Maruti Suzuki’s commitment to the environment, Kenichi Ayukawa, managing director and CEO, Maruti Suzuki, said, “Maruti Suzuki is working systematically to reduce vehicle emissions and the impact of manufacturing on the environment. Our innovative vehicle platform, Heartect helps us to lower CO2emissions between 6 to 8 percent even as it enables us to offer a superior drive performance. Going forward, we will continue our focus on investing in new technologies and further bring down CO2 emissions per vehicle.”

He added, “As part of our effort to use renewable source of energy, in this fiscal we plan to install a 5MW solar power plant at our Gurgaon campus. At Manesar, our existing 1MW solar power plant will be complemented by an additional 0.5MW solar plant.”

On the product designing front, Maruti Suzuki has developed full vehicle virtual validation capability, which has helped to induce efficiency in the product development processes. This leads to reduced physical testing of vehicles. Such virtual validation techniques help to reduce carbon footprint.

Riding the green value chain

Maruti Suzuki says it has a stringent Green Procurement Policy in place where all partners are encouraged to align with Green Procurement guidelines. More than 85 percent vendor plants have already acquired ISO -14001 certification and others are on course.

The company says it will soon adopt the International Material Data capturing system to study parameters like ASR (Automotive Shredder Residue), RRR (Reuse, Recycle and Recover) and substances of concern (like Pb, Hg, Cd, Cr) across all models so that prohibited substances can be identified and eliminated. This initiative will strengthen the end-of- life system (ELV) for vehicles.

For exports, Maruti Suzuki plans to align with the European Union system of classification, labelling and packaging of chemical substances adopt VCI Packaging (Volatile Corrosion Inhibitors) guidelines for packaging materials. By aligning with EU norms, the disclosures on components will be comprehensive.

RELATED ARTICLES

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

Maruti Suzuki expands capacity at Manesar plant by additional 100,000 units

New assembly line at Plant A expands total manufacturing capacity at the Manesar plants to 900,000 units per annum. Alon...

By Autocar Pro News Desk

By Autocar Pro News Desk

05 Jun 2018

05 Jun 2018

5239 Views

5239 Views