Hyundai India opens global quality and training centre in Faridabad

The India Quality Centre, one of five Hyundai Quality Centres worldwide, will focus on developing zero-defect vehicles.

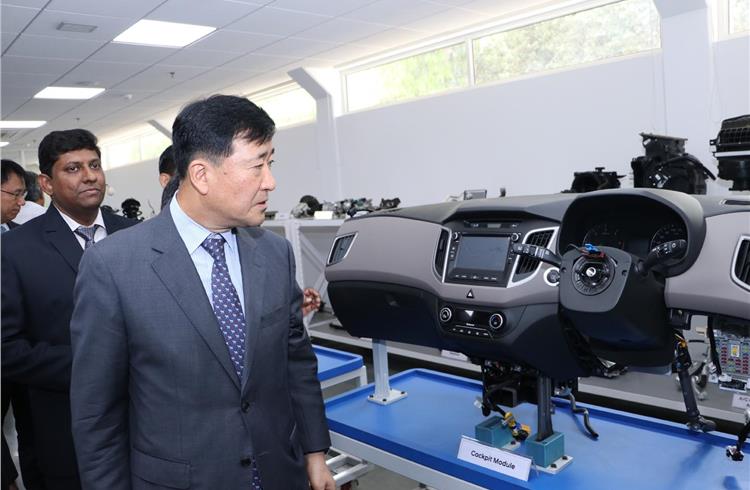

Hyundai Motor India today inaugurated its first centralised integrated quality and training centre in the country, located in Faridabad, in the Delhi-NCR region. It is the fifth such facility in Hyundai Motor Company’s global operations, with the other four locations being North America, Europe, Africa and China.

The new facility, spread over 72,000 square feet, is a state-of-the-art multi-disciplinary unit which incorporates a Quality Centre, Training Centre as well as Parts Quality Centre, under the same roof.

Hyundai’s vision in bringing together the three major cross-functional market quality operations was to also bring the India Quality Centre (INQC) out of the company’s main manufacturing premises in Chennai so as to cater to the geographic challenges offered by the Indian sub-continent, and improve product quality, to achieve its target of building ‘Zero Defect’ products, by understanding varied customer needs in different parts of the country.

Speaking at the inauguration of the INQC facility, Y K Koo, MD and CEO, HMIL said, “With the opening of India Quality Centre, Hyundai Motor further aims to reinforce its commitment to unmatched quality with focus on zero-defect vehicles. We will continue to focus on delivering top level of vehicle safety and bring innovative mobility solutions based on human-centric, eco-friendly technologies and services.”

According to Rakesh Srivastava, director (Marketing and Sales), Hyundai Motor India, “The INQC will take lead in new projects, right from their pilot stage, on ‘Top Level Safety Quality’ through proactive communications and understanding customer feedback to eliminate potential risks. The centre will also significantly monitor aspects including vehicle durability, unexpected safety issues, system and vehicle benchmarking and aid new model development, right until the mass production stage.“

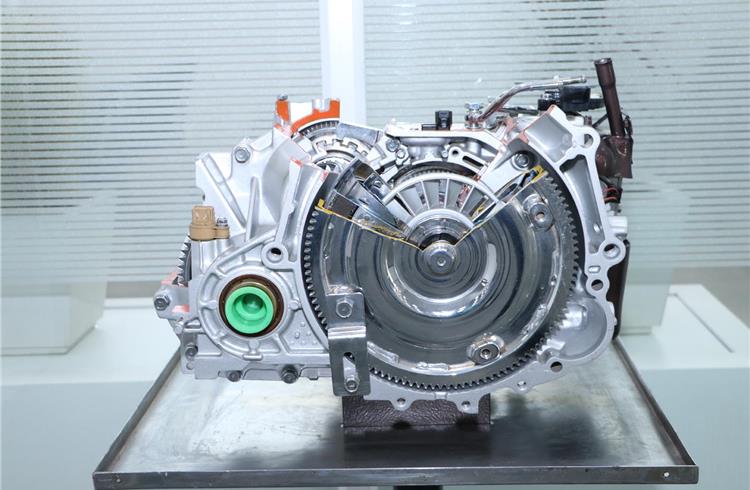

The INQC, along with the part centre, will also be responsible for quality assurance for all the exports being done by the company in the APAC region. To further speed up problem response and countermeasure initiation times, the facility also sees around 10 vendors from Korea, including PSC Valeo, Doowan and Hala Visteon, have their representatives positioned inside the premises itself, to react to consumer complaints quickly.

Training Centre to enhance staffer skills

The integrated INQC, which sees an investment of Rs 30 crore, incorporates a world-class training centre, equipped with an integrated body and paint training shop as well, which is the fifth regional centre to have such a setup, in Hyundai India’s total pool of six at the moment. Two more are slated to become functional by the end of CY2017 and will come up in Guwahati and Ahmedabad.

Its second major division in the Faridabad facility, the training centre will focus on imparting technical, soft skills, as well as managerial training to recruited associates, to then work in different verticals at the dealer and workshop level.

In line with the Skill India initiative, and as part of its CSR activities, the Korean carmaker has already started tying up with ITIs in every state and aims to grow to 48 collaborations by the end of 2017, from the current number of 38. The initiative sees close to 95 percent of the student population being roped in to work in various different entities in the Hyundai India ecosystem itself.

In an effort to move a level up in the skill set of the talent pool it acquires, the company is also associating with polytechnic colleges across India for employment generation, the first one having come up with PUSA in New Delhi.

Hyundai says it views skill enhancement as a continuous process and a very important one for its future plans in the country, as it goes on to introduce 8 new products, along with new technologies like mild-hybrid, AMT and turbocharged petrol engines, in its portfolio, by the year 2021.

The company, which services around 53 lakh vehicles annually, across its 1,253 strong workshop network in the country, aims to grow at 8 percent in FY2017-18, projecting a total sales number of 672,000 units.

It currently employs around 7,300 technicians and 3,300 service advisors and has switched nearly 220 of its service centres, most having service volumes of more than 400 cars a month, to complete digital and paperless customer service and repair job initiation systems, utilising its GDS online interface.

RELATED ARTICLES

Tata Elxsi-Renesas MCU for EVs enables cost optimisation, speedier time to market

Modular, scalable design of Motor Control Unit enables integration across diverse EV applications. Claimed to be reduce ...

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

28 Apr 2017

28 Apr 2017

18735 Views

18735 Views

Autocar Pro News Desk

Autocar Pro News Desk