Daimler-BASF urban car concept comes a-visiting

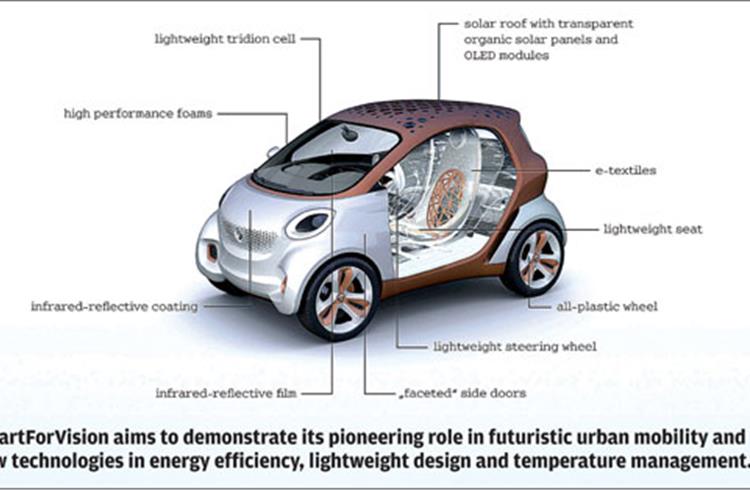

Combining electric drivetrain technology with new materials, the SmartForVision concept is reflective of the urban car of the future.

The Indo-German Urban Mela held last fortnight in New Delhi saw German exhibitors focus on sustainable urbanisation, showcasing futuristic designs of cars that use electric mobility for affordable city travel.

The ‘SmartForVision’ concept car, jointly developed by BASF and Daimler, and revealed at the 2011 Frankfurt motor show, was a huge attraction. While it combines new technologies in the areas of energy efficiency, lightweight design and temperature management, some highlights comprise the use of transparent organic solar cells, transparent organic light emitting diodes (OLEDs), plastic wheels, new lightweight body components and infrared-reflective films and coatings to reduce the vehicle’s energy consumption and increase its range and practicality. Some of the new materials and technologies used could also enable the electric car to generate energy as well.

|

While Daimler has contributed its expertise to the project, chemical products supplier BASF has clubbed together its materials and system competence to provide an eco-friendly solution for the energy-efficient mobility of tomorrow. The SmartForVision concept car uses a mixture of plastic materials and technologies, some still in the laboratory while others have a possibility of being leveraged for series production, says Prasad Chandran, chairman and managing director, BASF India.

The concept vehicle features power-generating solar cells based on organic-chemical dyes on the roof. Combined together with OLEDs, the vehicle’s roof, which is covered with solar cells, leads to lowering of CO2 emissions while creating a novel design.

A challenge to ensure continuing development of electric mobility is sustainably producing and using the power needed to drive cars. Moreover, the lighter an EV, the lesser drive energy it requires and the greater its range. Making vehicles lighter will, therefore, be a key challenge for electric mobility.

Composite materials

Lightweight design in turn means replacing heavy metal parts with composite materials that serve the same function and provide stability, for example, the chassis with fibre-reinforced plastics.

The SmartForVision features the first ever all-plastic wheels suitable for series production made from the high-performance Ultramid structure, developed by BASF. This material that is as strong as metal reduces weight by upto 30 percent. Each wheel saves 3kg in static conditions and in dynamic conditions can save upto 18kg, for all the wheels put together. At present the heating and air-conditioning systems in vehicles are major consumers of energy. The amount of energy required to cool or heat up the vehicle’s interiors can be reduced with the help of a temperature management system that uses polymer films in the windows to reflect thermal radiation and high performance insulating materials. The SmartForVision uses this technology in its concept.

BASF at it again

In February this year, BASF had exhibited its i-flow concept car developed jointly with Hyundai at the PlastIndia exhibition in Delhi. BASF contributed 25 solutions to the i-flow including energy harvesting systems like flexible solar panel roofing and a thermoelectric generator, energy conserving systems like engine encapsulation and weight saving materials for lightweight construction. Clearly, light weight and new tech is the way to go.

|

VW exhibits NILS single-seater electric concept

The Volkswagen Group India Exhibition Pavilion displayed the NILS, a single-seat electric concept vehicle that offers a glimpse of a new form of minimalist mobility. The aim is to work out a technically concrete and economically-feasible vehicle concept for micro-mobility, which restructures individual transportation to make it more efficient and eco-compatible based on electric drive technology.

Weighing just 460kg, NILS with its aluminium spaceframe, gullwing doors and free-standing wheels has been designed for commuters. Its basic structure without add-on parts or glass is produced from extruded aluminium parts, cast aluminium and sheet aluminium. The roof frame, together with the wing door mounts, a sturdy roll bar behind the driver, the bootspace and the front bulkhead consist of high-strength sheet aluminium. All add-on body parts are made of plastic and aluminium. The front and rear side body parts are made of aluminium. Parts made of high-strength plastic include the bumpers and trim panels on the side sills.

Prof Dr Jürgen Leohold, director, Volkswagen Group Research, says the influence of electric mobility and vehicle concepts like NILS are growing and these new vehicle concepts together with the electrification of existing models will help to advance electric mobility to a breakthrough.

To develop NILS, VW Group Research analysed all facets of commuter transportation with the aim of making it sustainable for the future. Some inputs for NILS were also provided by the Volkswagen Design Centre at Potsdam and despite its compact dimensions, NILS complies with all safety requirements for contemporary vehicles, explains Dr Ulrich Hackenberg, board member, Volkswagen AG.

With a range of 65km, the 130kph NILS can be a potential vehicle for German commuters. According to the German Federal Statistical Office, 73.9 percent of all commuters residing between Berlin and Munich cover less than 25km on their way to work. So, NILS is designed to be a reflection of a new era. NILS has also been designed to occupy less space in traffic and is 3.04 metres long, making it about 50cm shorter than the new VW Up. For the car’s electric drive system, engineers used VW’s experience in developing other concept cars such as the L1 and XL1 as well as future production vehicles like the Golf Blue-e-Motion or Up! Blue-e-Motion. The centrepiece of the drive unit is the lightweight 19kg electric motor together with its transmission and battery. Another important electronic assistance in NILS is City Emergency Braking, a software extension of the automatic distance control system.

RELATED ARTICLES

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

Maruti Suzuki expands capacity at Manesar plant by additional 100,000 units

New assembly line at Plant A expands total manufacturing capacity at the Manesar plants to 900,000 units per annum. Alon...

By Autocar Pro News Desk

By Autocar Pro News Desk

15 Nov 2012

15 Nov 2012

4143 Views

4143 Views