Carl Zeiss measuring machines gain momentum in Indian auto industry

As OEMs in India focus more on quality on the back of increasing customer awareness and government regulations, Carl Zeiss has positioned itself in the Indian market as a top-class measuring machine player in recent years.

Design is the basic element that decides the market reach of any product and its importance is felt much higher in the automotive industry. Production managers at vehicle and auto component manufacturing plants always prefer a standardised metrology infrastructure.

With developed and developing markets implementing restrictions on safety and emission control and, more recently in India, an increasing number of vehicle manufacturers are going in for high precision measurement solutions in their production process.

German automotive measuring machine manufacturer Carl Zeiss has just the equipment with which automakers and component producers can carry out quality inspection without any hassle.

Carl Zeiss’ measuring machines have, for long, been used by several OEMs, Tier 1s, Tier 2s and even Tier 3 companies to guarantee optimal quality assurance in production. It helps that the machines can be flexibly adapted to new products and generations, thus enabling considerable savings. At the same time, the measuring machines quickly deliver precise, detailed results.

As OEMs in India focus more on quality on the back of increasing customer awareness and government regulations, Carl Zeiss has positioned itself in the Indian market as a top-class measuring machine player in recent years.

To learn the latest about Carl Zeiss’ plans for India, Autocar Professional spoke with Daniel Sims, managing director, Carl Zeiss India (Bangalore) and Felix Hoben, member of the Management Board and Chief Operating Officer, Industrial Metrology Business Group, Carl Zeiss at Imtex Forging 2016, an international machine tool exhibition held recently in Bangalore.

Daniel Sims is clear that India is a key market for Car Zeiss in the Asian region. The Zeiss Group is a global technology leader operating in the fields of optics and optoelectronics. Any component fitted in a car – a connector, cable, engine parts, car body, seats, axle or even the dashboard – has something to do with metrology. For all parts, quality inspection is needed through measuring machines.

In addition to the automotive industry, Sims says the Zeiss Group provides solutions for biomedical research, medical technology, semiconductor and mechanical engineering industries.

Headquartered in Oberkochen, Germany, Zeiss has representatives in more than 40 countries. In India, the company is headquartered in Bangalore and present in the fields of industrial metrology, microscopy, medical technology, vision care and sports and cine optics.

Zeiss India started as a pure sales unit in 1998 and has developed into a full scale representation which now includes an R&D centre, 3 production facilities, global IT services and 30 sales and service offices in almost all Tier 1 and Tier 2 cities in India.

With nearly 600 employees and continued investments over 14 years in India, Zeiss is optimistic on further driving its growth story in India. According to Felix Hoben, the company has sold around 2,000 units of measuring machines since its inception in India.

Hoben says the Bangalore plant, set up in 2012, currently manufactures more than half of its machines sold in India. This unit is one among its four global production centres across the world, the other three being in Germany, China and the United States.

He adds that the company’s overall global sales stand at 4.5 billion euros (Rs 34,398 crore) including 400 million euros (Rs 3,057 crore) turnover from the automotive and related industries. Carl Zeiss has a presence in 42 countries including India.

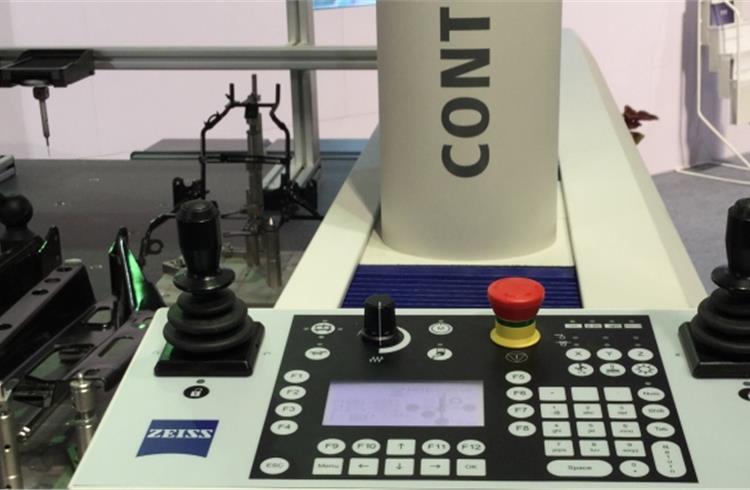

The Bangalore plant manufactures different variants of its measuring machine models like the Spectrum and Contura. Both these machines are fast moving models in India, primarily in the automotive sector. Its other measuring machines that are popular in the Indian automobile industry include Accura, Duramax, Gagemax, Prismo, O-Select and Metrotom.

The company also supplies many other models of measuring machines in India, imported from its overseas manufacturing facilities.

Providing additional details, Sridhar V Pissay, VP (Sales and Marketing), Industrial Metrology Division, Carl Zeiss India, says the company has sold around 280 machines in 2015. Its OEM customers in India include Tata Motors, Fiat, Hyundai Motor India, General Motors India, Maruti Suzuki India, Ashok Leyland, Ford India and Bajaj Auto. It also supplies its products to Tier 1 suppliers like Bosch, Continental and Denso in the country.

Sims says the company has been growing at 20 percent CAGR in the past 15 years in India. “We are introducing more products in the Indian market while expanding our business areas too. We are ambitious to maintain the same percentage of growth in the coming five years, which is possible,” he adds.

Commenting on the ‘Make in India’ concept, Heben says, the campaign encourages industrial metrology sector, where Carl Zeiss is present. “On the lines of this concept, we are making products of a global standard in India,” Heben adds.

Heben reveals that the company recently inaugurated its R&D Centre in Bangalore, which will cater to the research needs of the company’s global markets. Notably, it is third R&D centre for Carl Zeiss in addition to the existing ones in Germany and the United States.

The company has participated in the Imtex Expo regularly and this was the 13th time it was part of South East Asia’s premium machine tools trade fair.

RELATED ARTICLES

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

Maruti Suzuki expands capacity at Manesar plant by additional 100,000 units

New assembly line at Plant A expands total manufacturing capacity at the Manesar plants to 900,000 units per annum. Alon...

Hyundai and Kia partner Exide Energy to produce LFP batteries in India

Partnership with Exide Energy enables Hyundai Motor and Kia to equip future EVs in the Indian market with locally produc...

By Jaishankar Jayaramiah

By Jaishankar Jayaramiah

25 Jan 2016

25 Jan 2016

7747 Views

7747 Views