Bosch reaffirms India commitment

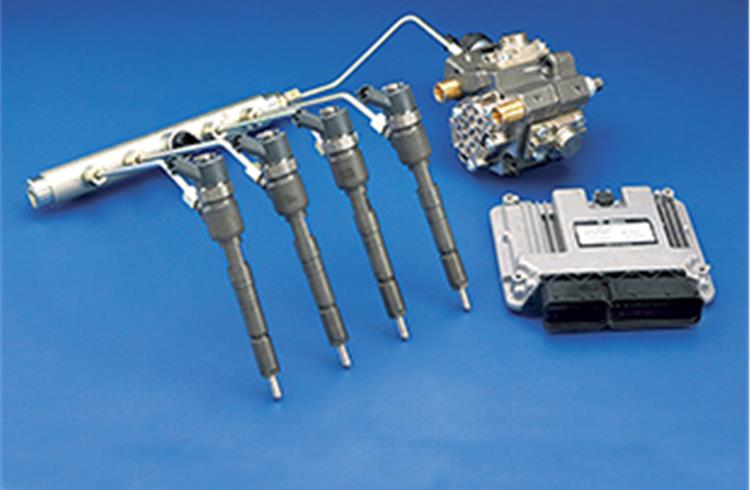

Bosch announced the launch of its common rail (CR) high pressure pump manufacturing facility in Bangalore.

On this important occasion, Bohr, Member, Board of Management, Robert Bosch GmbH reiterated his company’s commitment to the country. “We have been at the heart of developments in India for many years. Nowhere is this more apparent than in Bangalore which produces high pressure pumps for common rails and most advanced fuel injection systems. In addition, injector components have been leaving the assembly lines at Nashik since early this year and the manufacture of complete injectors will follow by 2007. All in all, we are investing Rs 550 crore in the production of common rail systems in India,” he said.

According to Bohr, the new manufacturing facility in Bangalore had been designed to meet the needs of local automakers which put a lot of emphasis on quality and quick development. “This not only involves investments but know-how of the product and it is for this reason that we are promoting intensive knowledge transfer among our plants around the world,” he said.

##### For instance, Bosch has assigned over 200 projects from Bangalore and Nashik to locations in Germany, Italy and Turkey. It has also been “grooming” Indian engineers to the extent that in 2005, 80 were stationed in Germany to share their experience of common rail development. This will be repeated this calendar with the same number of people. “We not only intend increasing production of common rail systems in India but also their development and application. Our Indian activities are an integral part of our international network,” he said.

Robert Bosch India, another arm based in Bangalore, had 2,900 associates on its rolls end-2005 and Bohr believed that this would be up to 3,600 associates by the end of this calendar of which 3000 would in software development. He added that software specialists from Bangalore and Coimbatore (the new development centre that starts work very soon) would play an important role in the company’s global development work.

Albert Hieronimus, managing director, MICO, said that the CR line in Bangalore would have a capacity of 1,000 CR pumps a day to meet the needs of the Indian market. It has been built on the principles of the Bosch production systems which aims at making the production process lean, productive and flexible. He said that the first phase of the Rs 550 crore investment by Bosch in India for CR technology had just been completed. This included setting up of the CR pump manufacturing facility in Bangalore and production of CR injector components at the Nashik plant.

“The Nashik plant is used only for export commitments but by the end of 2007, we will start manufacture of complete CR injectors for the local market. This investment will go a long way in making the CR technology easily available and more affordable to the Indian customer,” Hieronimus said.

The Nashik plant, incidentally, started export of CR injector components from January this year to Bosch Korea. He reiterated that the company was not merely investing in setting up a manufacturing facility but also in product development, applications and testing competencies. All this would cut short development time as was the case of the Mahindra Scorpio CRDe which was launched in record time. Bosch is looking at a staggering sales target of six lakh CR systems in 2010, which is a huge jump from the figure of 40,000 units sold in 2005. Bohr did not think this was particularly unrealistic to achieve.

##### As he explained, “India is becoming a country for diesels. There is also the issue of clean air and emission standards. Bharat Stage 3 has been imposed in 11 metros since 2005 and will become mandatory nationwide in 2010. Legislation in larger cities is expected to become a lot more stringent with BS 4.

“Clean air can be achieved with good direct injection engines fitted with common rail systems. In Europe, every second car is a diesel thanks to the benefits better fuel efficiency and clean air. Diesel is also gradually gaining some ground in China and the US. Between now and 2010, diesel’s share in Indian car and UV segments is expected to cross 40 percent.”

Bohr also drove his point home saying that last year alone, India’s crude oil consumption grew by ten percent with indications that it will increase even further. This makes economical engines even more relevant. “On an average, the diesel engine consumes 30 percent less fuel than a petrol engines. This means that Indian buyers can save considerably in the process given that they also pay less for diesel,” he said.

India, Bohr said, had everything going in its favour at present. “For Bosch, what is of special importance is the ambitious road construction programme. In India, freeways still make up only two percent of the road network that are used by 40 percent of traffic. “This year, we will see the completion of the golden quadrilateral (6,000 km of freeways linking the main cities). However, there is still a lot to do and almost 50,000 km of roads need to be widened. There is also a need to regulate supplies of power and water. All this will give a boost to India’s economic development,” he said.

Bohr also observed that India was Asia’s fourth largest car market with sales growing by 20 percent annually. Given this growth, it could be among the world’s five largest industrial markets. “At present, only seven out of 1,000 people in India is a car buyer,” he said. Bohr saw interesting prospects in the fact that India was the world’s second largest bike market where one-fourths of buyers were planning to graduate to a car. “This translates into additional sales of one million cars a year. In this connection, cars costing less than Rs 4 lakh will be in demand,” he noted.

RELATED ARTICLES

Bosch hydrogen engine tech-powered truck to be on Indian roads this year

The global supplier of technology and services is betting big on both electromobility and hydrogen. While announcing the...

IIT Bombay inaugurates Arun Firodia Research Floor

IIT Bombay, one of India’s top technical and research institutions, honours Kinetic Group chairman Dr Arun Firodia, one ...

Maruti Suzuki expands capacity at Manesar plant by additional 100,000 units

New assembly line at Plant A expands total manufacturing capacity at the Manesar plants to 900,000 units per annum. Alon...

By Autocar Pro News Desk

By Autocar Pro News Desk

14 Aug 2006

14 Aug 2006

3826 Views

3826 Views