Yamaha Motor to utilise Siemens' software solution for product development

Yamaha Motor, plans to deploy NX and Teamcenter across all motorcycle development processes globally that will create a fully integrated 3D product development process and an efficient integrated management environment for 3D master data.

Yamaha Motor has selected Siemens to provide product lifecycle management (PLM) software to support its digitalisation initiative. The Japanese bikemaker will deploy Siemens’ Teamcenter that provides digital lifecycle management software, across all development divisions of its key business and motorcycle products. Yamaha will also adopt Siemens’ NX software for integrated computer-aided design, manufacturing and engineering (CAD/CAM/CAE) for its design development system.

By adopting NX and the Teamcenter platform, Yamaha will further enhance the digital design process, facilitating efficient and direct collaboration between product development designers and engineers.

"Improving the development process for our motorcycles, which constitute our main product, holds great meaning for our company," said Makoto Shimamoto, senior executive officer and chief GM, PF Model Unit at Yamaha Motor. "Utilising software from Siemens can help us achieve quality improvements that will lead to shorter development times, reduce workload, and enable the designers to spend more time on creating innovation. We expect that working with Siemens PLM Software will help us achieve the business goals of higher business efficiency and product competitiveness."

Yamaha Motor, plans to deploy NX and Teamcenter across all motorcycle development processes globally that will create a fully integrated 3D product development process and an efficient integrated management environment for 3D master data. NX, used for digital design and engineering analysis, will enable designers to work more efficiently and collaboratively, enabling shorter time to market and faster innovation cycles. Using Teamcenter as the digital thread across the product development process will allow global teams to work with a single source of the latest product data.

In the future, Yamaha Motor will be able to build on this foundation to establish digital processes which link design with manufacturing technology, to realise the digital enterprise throughout the entire process, from design to production.

"With the environment surrounding the manufacturing industry significantly changing in recent years, we believe that digitalization enables continuous business transformation and innovation," said Kunihiko Horita, country manager, Siemens PLM Software, Japan.

RELATED ARTICLES

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

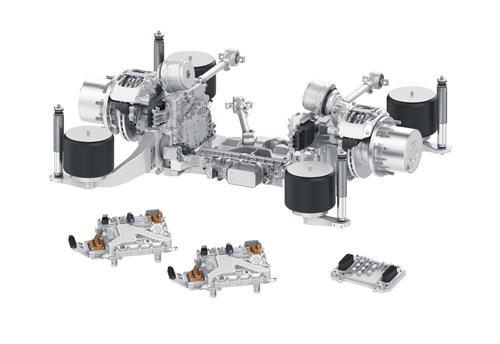

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

07 Sep 2017

07 Sep 2017

11807 Views

11807 Views

Autocar Pro News Desk

Autocar Pro News Desk