Toyota incorporates a robot to test durability in new Avalon

Toyota incorporates a new robot for testing Avalon for its rough road durability.

Toyota has replaced the human test driver with a robot that would endure all the harshness of the tough durability test. It is being tried out for the testing of the new Toyota Avalon.

The rough road durability testing for Toyota’s North American vehicles is conducted on a course in Michigan that the company has specifically engineered with potholes, dips and other defects precisely placed along the track surface. These conditions inflict all the road-induced punishment that the average vehicle encounters during its lifetime into a single, bone-jarring evaluation.

This spares engineers and technicians from conducting the evaluations through this very uncomfortable ride which involves continuously circling around the pothole-filled track. As they are required to drive the vehicle at specific speeds till the necessary mileage were accumulated in the vehicle, Toyota decided to let a robot perform the test.

Toyota stresses that this is not an automated vehicle, but a simpler robotic solution using a combination of computers, actuators, levers, other mechanicals and a lot of engineering know-how. In fact, the system doesn’t utilise any of Avalon’s many advanced driver assistance or navigation features, nor any of the advanced LIDAR, sensors, and cameras used by the autonomous vehicles being developed by Toyota Research Institute (TRI).

According to Avalon chief engineer Randy Stephens, “This not only saved the engineers and technicians from having to endure the gruelling ride, it also provided a more accurate test cycle. The system was proven during Avalon development, and we plan to use it during all future North American vehicle development cycles.”

The robot is a set of components that could remotely start, shift, steer and stop the Toyota flagship vehicle. Traditional in-car global positioning systems are accurate to about four-metres, but Toyota’s VPD team developed the path control software with an accuracy of within two centimetres.

The complete navigation infrastructure allows the engineers and technicians to monitor the test from a nearby control room without the need for humans to physically occupy the vehicle through harsh testing conditions. Another benefit of the robot behind the wheel is that the test cycles were now limited by fuel capacity, instead of stopping every 30-40 minutes for swapping drivers.

Toyota's robot undergoes the harsh durability test in new Avalon.

The robot is exclusively in use by Toyota’s North American R&D headquarters in Michigan. However, the company intends to explore possible applications of the system at other Toyota R&D facilities in the future.

RELATED ARTICLES

Nissan shows in-construction all-solid-state battery pilot line in Japan

Under the Nissan Ambition 2030 long-term vision, Nissan aims to launch EVs equipped with the batteries by fiscal year 20...

BMW Group sells 82,700 BEVs in Q1 2024, sees growth across all key markets

The company has delivered a total of 82,700 fully-electric BMW, Mini and Rolls-Royce vehicles to customers worldwide, up...

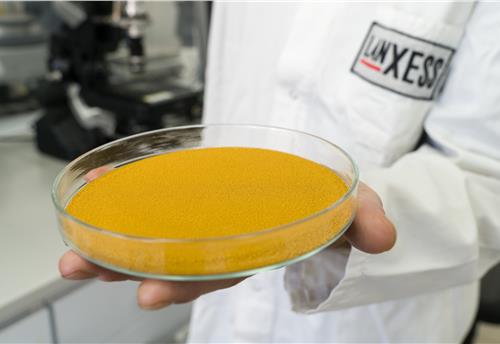

Lanxess and IBU-tec to develop iron oxides for LFP EV batteries

Collaboration aims to improve performance of LFP cathode material; reduced carbon footprint of batteries through use of ...

By Autocar Pro News Desk

By Autocar Pro News Desk

15 Mar 2018

15 Mar 2018

9058 Views

9058 Views