ROHM and A-Star’s to develop AI chip for smart factories

To improve asset productivity and lower maintenance costs, the AI chip will collect and interpret data from sensors and will provide prediction on machine failures.

ROHM Semiconductor and A-STAR’s (IME) Institute of Microelectronics a research institute under the Agency for Science, Technology and Research have announced the joint development of an artificial intelligence (AI) chip to boost efficiency in predictive maintenance for smart factories.

The concept of predictive maintenance has become widespread in the manufacturing industry as manufacturers begin to digitalise their production lines for increased productivity and competitiveness. Predictive maintenance forecasts machine failures and identifying potential problems based on data received through device logs and sensors, and eventually taking counter-measures such as repairing or replacing the affected machine.

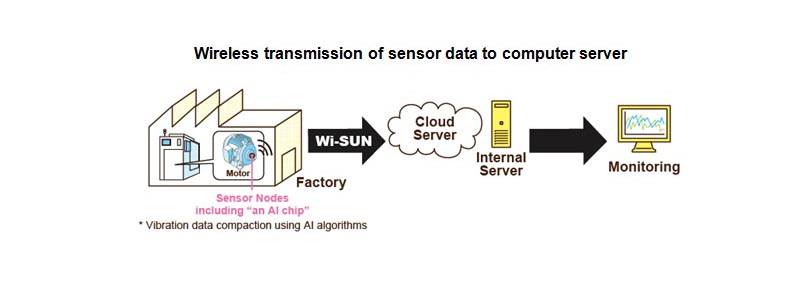

In order for any machine abnormality to be detected throughout a production line, diverse amounts of data gathered from multiple sensors are first transmitted over a wireless network to a central computer server for processing and analysis. However, as the number of sensors increases in the future, the wireless communication technology for wireless sensor networks would face bandwidth constraints, and be unable to expeditiously transmit the increasingly large sensor data to the computer server.

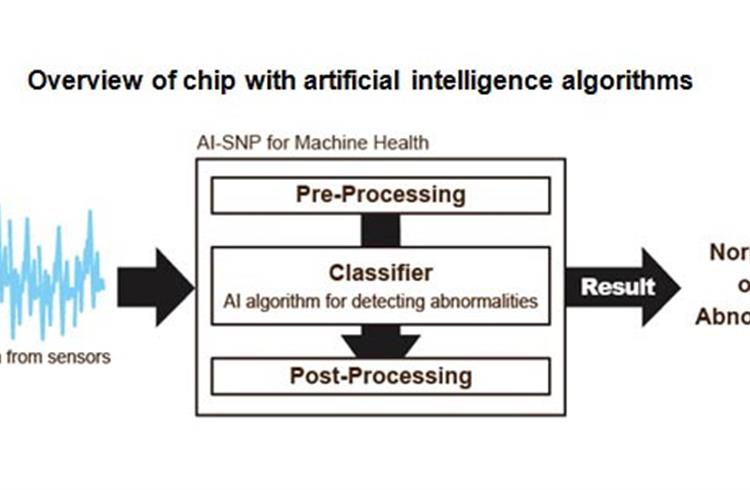

ROHM and IME will develop an AI chip that is capable of processing and analysing data as soon as they are received by a sensor node. This drastically reduces the amount of sensor data to be transmitted wirelessly to a central computer server for them to be further processed and analyzed.

“Through the fusion of ROHM’s sensor technology, analog low-power technology and AI architecture with IME’s capabilities in low-power integrated circuit technology, we want to provide the optimum solutions for edge nodes,” said Koji Taniuchi, fundamental research and development division, GM, ROHM.

“The factories of tomorrow will demand highly intelligent solutions for greater integration of their operations in a seamless network across the value chain,” said Dr Tan Yong Tsong, executive director, IME.

RELATED ARTICLES

Kia displays EV5 and Sonet SUVs for Chinese market

Kia has unveiled a number of key models and new technologies for Chinese customers at the 2024 Beijing International Aut...

Nissan targets growth in China, unveils four NEV concepts at Beijing Motor Show

The two EVs and two plug-in hybrids are a joint effort with Nissan’s local partner Dong Feng and aimed to better address...

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

22 Jun 2017

22 Jun 2017

3418 Views

3418 Views

Autocar Pro News Desk

Autocar Pro News Desk