Revolutionary engine valve tech gives petrols the efficiency of diesels

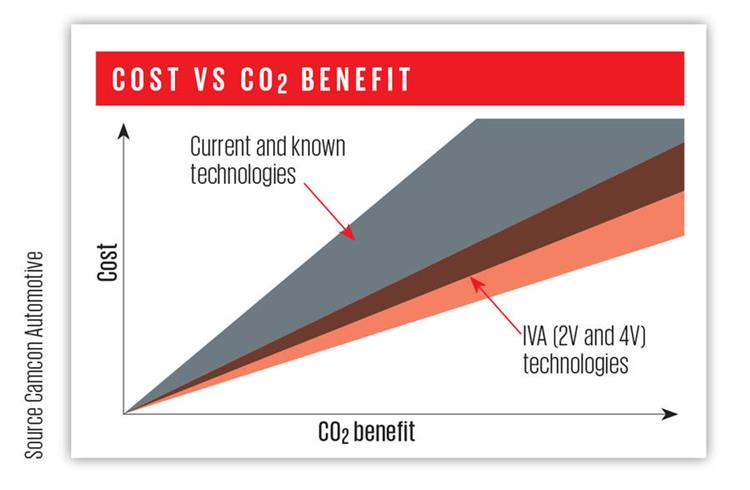

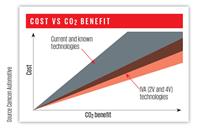

The digitally controlled intelligent valve operation betters the fuel economy and engine flexibility of petrols.

A revolutionary, British-designed digital valvetrain drive system called IVA, claimed to give petrol engines the driveability and economy of diesels but with more benign and manageable emissions, has been revealed by Leamington Spa-based technology firm Camcon Automotive.

IVA, or Intelligent Valve Actuation, has been under development for the past six years, reaching a sufficient stage of maturity in bench tests for road trials to begin. IVA is now being offered to major manfacturers and component suppliers for development as an efficiency boost for use in both normal and hybrid cars.

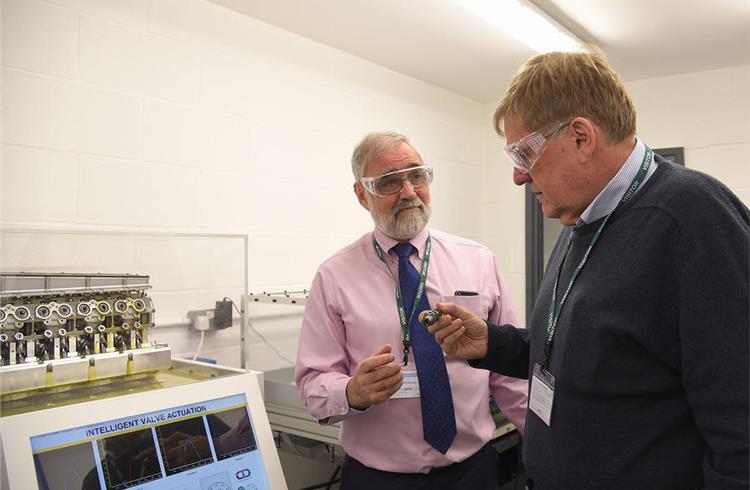

According to Camcon technical director Roger Stone, who has led IVA’s development from the start and describes himself as “a lifelong engine man”, the system allows valve lift, valve timing and duration to be independently and infinitely controllable. This breaks the previously unbreakable mechanical link between valve operation and the rotation of the crankshaft that has been a factor in all piston engine design for well over a century.

IVA’s inventors describe it as a step-change in engine design that removes the last remaining analogue system, saying it is “probably even more important than the switch from points ignition to engine management, or carburettors to fuel injection”.

With completely flexible valve actuation, there’s high potential for an engine to be configured entirely according to a driver’s needs, delivering extreme flexibility in lowspeed, low-load situations, with very high power when needed.

The necessary compromises imposed by conventional camshaft timing — and by existing less advanced variable valve timing systems — are removed. IVA is especially adaptable to sophisticated cylinder deactivation — a likely further boost to efficiency.

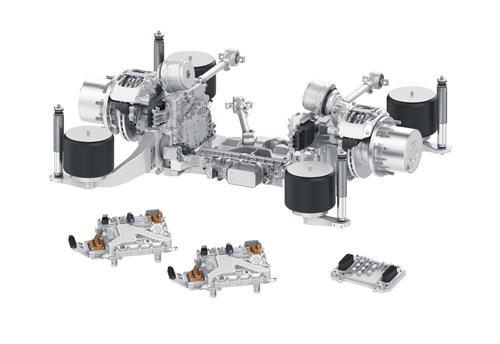

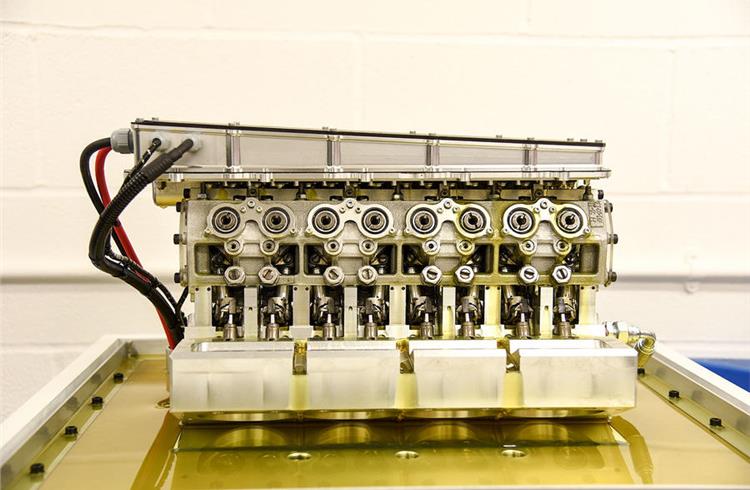

The key to IVA has been the development of a system of electromechanical actuators that sit on top of the engine, each driving a short camshaft that opens a valve or valve pair. In an experimental engine shown to Autocar UK, there are eight of these actuators and camshafts running across the engine, rather than along it. Valve drive is desmodromic (valves are positively closed as well as opened) and the opening/closing regimes are controlled by a management computer. This is currently housed in a large metal box atop the engine, and in production is likely to be linked to existing ECU functions.

“IVA allows incredible control,” says Stone. “We can achieve full lift by rotating the camshaft through 360deg, or achieve any intermediate lift we like by rotating it part of the way and rotating it back again. It’s designed to fit pretty much any engine.”

Camcon has already acknowledged technical help from Jaguar Land Rover, which is based nearby and is understood to be keeping tabs on developments. Camcon plans a programme of both test rig and road trials to test IVA’s durability and record real-world results, but commercial director Mark Gostick believes the system has already gone a long way to proving its durability. If adopted by a supplier in the Bosch or Valeo mould, IVA would take two to three years to reach production, Camcon believes, and has the potential to be developed in productive new directions beyond that.

RELATED ARTICLES

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

26 May 2017

26 May 2017

5648 Views

5648 Views

Autocar Pro News Desk

Autocar Pro News Desk