Refinery at Ma’aden-Alcoa JV produces first alumina from Saudi bauxite

The Saudi Arabian Mining Company (Ma’aden) and lightweight metals leader Alcoa today announced that the alumina refinery

The Saudi Arabian Mining Company (Ma’aden) and lightweight metals leader Alcoa today announced that the alumina refinery at their joint venture aluminum complex in Saudi Arabia has successfully produced its first alumina from Saudi Arabian bauxite. The alumina refinery at Ras Al Khair is the first ever refinery to be constructed and operated in the region.

The milestone marks the commencement of the final link in the supply chain of this fully integrated aluminum facility. The alumina refinery will refine Saudi Arabian bauxite, supplied from Ma’aden Aluminium’s mine at Al Ba’itha and transported by 600km rail to Ras Al Khair. The alumina from this refinery will feed into the Ma’aden Aluminium Smelter which produces the aluminum needed for the Ma’aden Aluminium Rolling Mill. This fully integrated chain delivers operational efficiency and creates the most competitive aluminum complex in the world.

Once fully operational the refinery will produce 1.8 million mtpy of alumina. The alumina will be transported by conveyor to the adjacent smelter to produce 740,000 mtpy of high quality aluminum products for customers in the Gulf region and in international markets.

“We are building a minerals and metals industry in Saudi Arabia that maximizes the value of the nation’s mineral resources; contributes to sustainable economic diversification and shareholder value; provides high value job opportunities for Saudis and a reliable supply of quality products to our global customers. This milestone marks a significant moment for our industry in Saudi Arabia and the broader GCC region,” said Khalid Mudaifer, President and CEO of Ma’aden.

“As the lowest cost aluminum complex in the world, the Ma’aden Alcoa joint venture is an important plank of Alcoa’s strategy to create a globally competitive commodity business,” said Klaus Kleinfeld, Alcoa Chairman and Chief Executive Officer. “The first alumina milestone is another demonstration of our disciplined execution as we transform Alcoa to create sustainable shareholder value.”

In its initial phases, the joint venture will develop a fully integrated industrial complex which will become the world's preeminent primary aluminum, alumina and aluminum products, with access and proximity to growing world markets. The complex comprises a bauxite mine with an initial capacity of 4,000,000 metric tonnes per year; an alumina refinery with an initial capacity of 1,800,000 metric tonnes per year; an aluminium smelter with an initial capacity of 740,000 metric tonnes per year; the rolling mill, with initial capacity of 380,000 metric tonnes per year.

Jaguar Land Rover to benefit

In end-2012 Jaguar Land Rover (JLR) had signalled its intention to eventually build a production plant in Saudi Arabia. With emissions reduction and improved fuel economy top-of-mind, carmakers are increasingly turning to aluminium to make their cars lighter and, therefore, more fuel-efficient.

In December 2012, a letter of intent had been signed between JLR and the National Industrial Clusters Development Program (NICDP) with the backing of the Saudi government and Prince Faisal Bin Turki bin Abdul Azi Al Saud.

Having a production base in Saudi Arabia will make sound business sense as JLR will be able to secure a steady supply of aluminium as global demand for the light metal starts to rise.

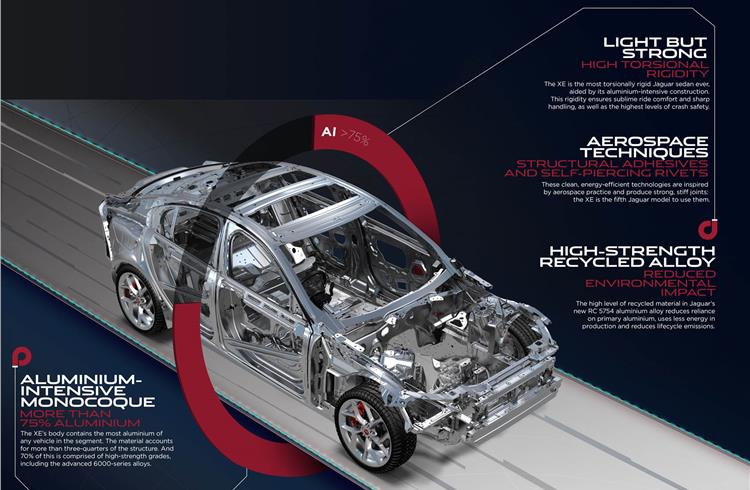

Lightweight construction is a core element of Jaguar's DNA and Jaguar is at the cutting-edge of aluminium technology in the automotive industry. The Jaguar XJ, XK and F-Type have all been developed using exceptionally stiff bonded and riveted aluminium structures. More recently, the XE becomes the latest model to use this aerospace-inspired technology and brings new levels of aluminium-intensive lightweight construction expertise to the segment.

RELATED ARTICLES

Kia displays EV5 and Sonet SUVs for Chinese market

Kia has unveiled a number of key models and new technologies for Chinese customers at the 2024 Beijing International Aut...

Nissan targets growth in China, unveils four NEV concepts at Beijing Motor Show

The two EVs and two plug-in hybrids are a joint effort with Nissan’s local partner Dong Feng and aimed to better address...

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

By Autocar Pro News Desk

By Autocar Pro News Desk

22 Dec 2014

22 Dec 2014

2719 Views

2719 Views