RapidSR: Ricardo’s next-gen EV motor

Ricardo has designed and built in prototype form a new electric vehicle (EV) motor as part of a collaborative R&D project, RapidSR

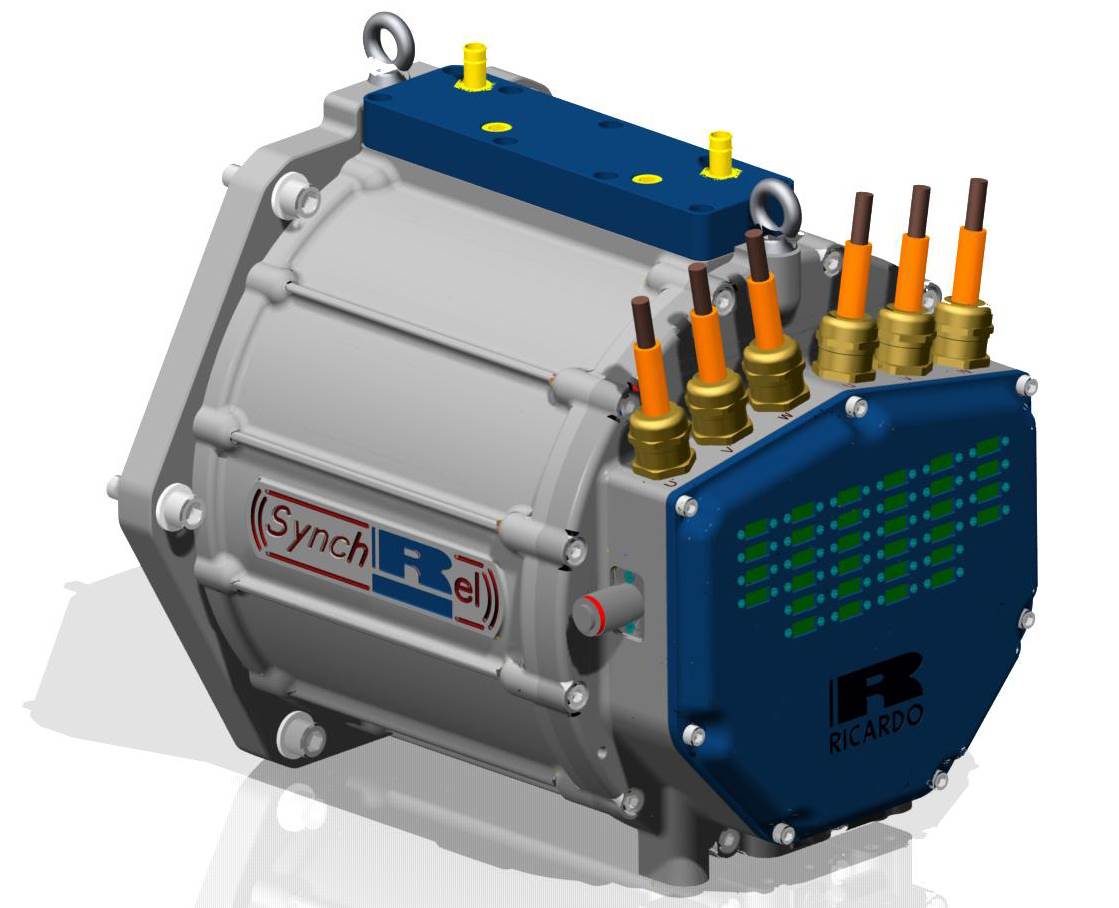

Ricardo has designed and built in prototype form a new electric vehicle (EV) motor as part of a collaborative R&D project, RapidSR (Rapid Design and Development of a Switched Reluctance Traction Motor).

Using a conventional distributed stator winding, the Ricardo synchronous reluctance electric machine is a highly innovative design that makes use of low-cost materials, simple manufacturing processes and uncomplicated construction. It has a rotor made from cut steel laminations, which are used to direct and focus the flux across the air gap. By maximising this flux linkage between the stator and rotor, performance can be optimized within a tightly packaged, low weight and rare earth element free design.

“As the market for electric vehicles grows globally, there is an imperative to explore alternatives to permanent magnet traction motors which require the use of expensive and increasingly difficult to source rare earth elements,” said Paul Rivera, MD of the Ricardo hybrid and electric vehicle systems business. “The Ricardo prototype that we have announced today demonstrates what can be achieved by using the latest electric machine design processes in the creation of a high performing, compact, lightweight, and rare earth element free concept.”

Since its launch in 2012, the RapidSR project has been researching the design of next-generation economic electric motors that avoid expensive and potentially difficult to source rare earth elements typically used in permanent magnets. By developing effective CAE-led design processes as well as prototype designs, the team has created a framework for the future design and manufacture of electric vehicle motors that offer the performance, compact packaging and light weight required for EV applications, but at a significantly reduced cost compared to permanent magnet machines. Ricardo’s partners in this research include project leader Cobham Technical Services – which is developing its multi-physics CAE design software, Opera, as a part of the project – and Jaguar Land Rover. The research is being co-funded by the UK’s innovation agency, Innovate UK.

“By bringing together state-of-the-art simulation technology with advanced electric machine design we have created a highly credible next generation EV motor concept that shows considerable promise,” added Dr Will Drury, Ricardo team leader for electric machines and power electronics. “The Ricardo prototype is now built and will be rigorously tested over the coming weeks in order to validate the extremely positive results that it has shown in simulation, as a concept that provides an exceptional balance of performance, compact package, light weight and low cost.”

RELATED ARTICLES

Hyundai and carbon fibre specialist Toray to develop lightweight, high-strength materials

Partnership aims to secure capabilities to develop lightweight and high-strength materials for environmentally friendly ...

Yamaha wins Red Dot product design awards for MT-09 and XMAX 300

The latest awards mark the 13th year in a row – every year since 2012 – that a Yamaha Motor product has received a Red D...

Honda reveals new Ye series of EVs for China

A second set of Ye EVs will be revealed in the coming months, completing the six-car line-up for China.

By Autocar Pro News Desk

By Autocar Pro News Desk

27 Feb 2015

27 Feb 2015

5101 Views

5101 Views