Mercedes-Benz opens new crash test centre

The new Vehicle Safety Technology Centre (TFS) will allow vehicle-vehicle tests, designing assistance systems and Pre‑Safe and for the validation of vehicle concepts involving alternative drive systems.

Mercedes-Benz has crash tested an E-Class Saloon to mark the opening of what the company describes as the world's ultimate state-of-the-art crash test centre, built at its site in Sindelfingen, in Stuttgart, Germany.

The new Vehicle Safety Technology Centre (or TFS, the German for its name), was inaugurated in the presence of the Minister President of the German state of Baden-Württemberg, Winfried Kretschmann. The test centre opens up new opportunities for vehicle-vehicle tests, designing assistance systems and Pre‑Safe and for the validation of vehicle concepts involving alternative drive systems. The investment amounts to a three-digit million euro sum.

In his welcoming address, Minister President Kretschmann said, “The automotive industry is currently experiencing the most radical upheaval in its history. The companies are working to invent the automobile all over again. The car of the future will form part of a digitally networked mobility system and, as such, will drive autonomously and with zero emissions. But for all this, one thing will remain the same: the need of customers for safety. Daimler AG's new Vehicle Safety Technology Centre underscores the tremendous importance that the company gives to the issue of vehicle safety.”

“The state government here in Baden-Württemberg will continue to extend its efforts to promote automated and autonomous driving. The issue of safety will of course also play an important part in this. Our vision has to be: no more traffic fatalities,” he added.

L-R: Prof. Dr. Thomas Weber; Winfried Kretschmann; Dr. Dieter Zetsche

Also commenting on the occasion, Dr Dieter Zetsche, chairman of the board of management of Daimler AG and head of Mercedes-Benz Cars said, “In recent years we have extensively expanded the Mercedes-Benz Technology Centre in Sindelfingen: following the driving simulator, wind tunnels and Powertrain Integration Centre, the Vehicle Safety Technology Centre has now been taken into operation. This once again demonstrates that the heart of the automotive industry beats in Sindelfingen. To make sure that this remains so, Mercedes-Benz has reinforced Germany's status as a high-tech location with this investment in the future, while safeguarding the company's technology and innovation leadership in the premium segment.”

New test possibilities for Mercedes-Benz

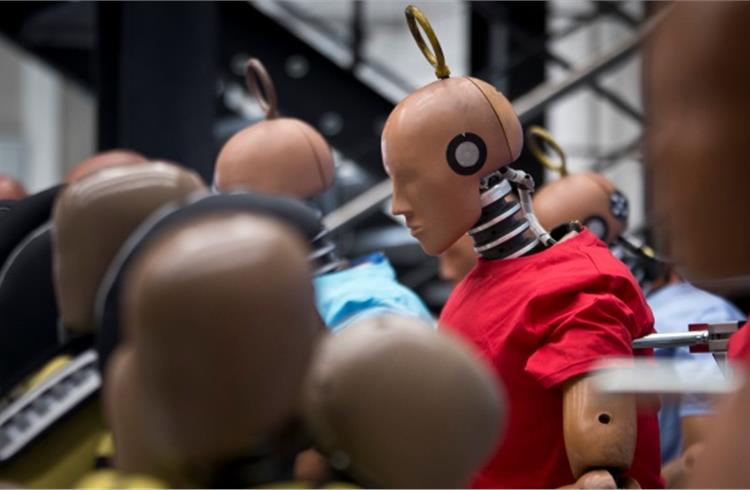

The numerous test facilities in the new TFS will assist Mercedes-Benz in its role as a pacemaker. Around 900 crash tests can be carried out each year, thanks to the new operating concept and the flexible system layout. There is also capacity for around 1,700 sled tests per year.

As Prof. Dr Thomas Weber, member of the board of management of Daimler AG, Group Research & Mercedes-Benz Cars Development, explained: "With its new technology centre for vehicle safety, Mercedes-Benz is once again asserting its commitment to the core brand value of 'safety', and to Germany as a location for innovation. The close integration of research, development, planning and production at the Sindelfingen site will ensure improvements in both efficiency and the speed of innovation. The generously proportioned building and extensive testing facilities we have here will ensure that Mercedes-Benz can in future continue to set the pace for the global automotive industry."

Crash hall larger than a football field

Construction of the new Vehicle Safety Technology Centre (TFS) has involved the investment of a triple-digit million euro sum. Initial planning began more than 10 years ago, with building work starting in the autumn of 2013. The topping-out ceremony was on May 12, 2015, while the first productive crash test was conducted on September 30, 2016.

At 90 metres by 90 metres, the column-free area of the crash hall is significantly larger than that of an international-standard football pitch. The longest crash-test run is over 200 m in length. More than 7,000 tonnes of steel were used, while the 36,000 cubic metres of concrete used may be visualised as an approximately 40km long queue of concrete mixer trucks. The structural features also include temperature control using the waste heat from the adjacent climatic wind tunnels.

RELATED ARTICLES

Kia displays EV5 and Sonet SUVs for Chinese market

Kia has unveiled a number of key models and new technologies for Chinese customers at the 2024 Beijing International Aut...

Nissan targets growth in China, unveils four NEV concepts at Beijing Motor Show

The two EVs and two plug-in hybrids are a joint effort with Nissan’s local partner Dong Feng and aimed to better address...

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

By Autocar Pro News Desk

By Autocar Pro News Desk

02 Dec 2016

02 Dec 2016

6069 Views

6069 Views