Lanxess helps develop polyamide oil pans for trucks

Specialty chemicals company Lanxess has contributed towards development of the oil pans fitted in the 12.8-litre Euro 6 engines for the Mercedes Actros from Daimler.

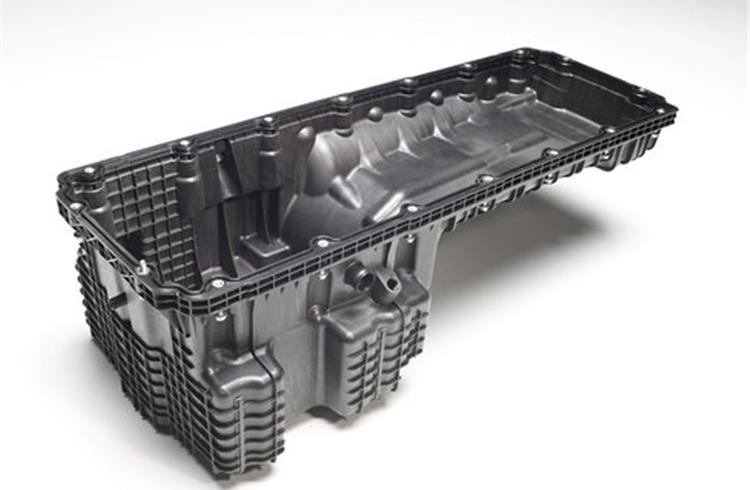

Specialty chemicals company Lanxess has contributed towards development of the oil pans fitted in the 12.8-litre Euro 6 engines for the Mercedes Actros from Daimler. At up to 120cm long, 40cm wide and 35cm deep, they are the largest engine oil pans for trucks to be made of polyamide 6 and 66. They are manufactured by Marbach-based BBP Kunststoffwerk Marbach Baier GmbH using Durethan from Lanxess.

“We used a series of calculations and simulations to confirm the feasibility of the oil pans in advance, thus helping to ensure that the pans could be designed on the computer properly and cost-effectively over a relatively short development period,” said Frank Krause, a Lanxess expert for oil-carrying engine parts made of plastic.

In this particular application, polyamide offers an alternative to aluminium, sheet steel and sheet molding compounds (SMC). It produces far lighter components than die-cast aluminium, for example. What's more, polyamide components made using injection molding processes are ready for use straight away. In contrast, die-cast and SMC parts often have to undergo laborious and costly additional processing in order to remove burring, for example.

One variant of the oil pan for the 12.8-litre engine is made of the heat-stabilised polyamide 66 Durethan AKV 35 H2.0 filled with 35 percent glass fibres, while the other is manufactured using the corresponding polyamide 6 grade Durethan BKV 35 EF H2.0. “In the course of the joint development work, it transpired that polyamide 6, too, is able to cope with the high demands made on these large components that are exposed to a range of temperatures and pressures,” said Krause. Durethan BKV 35 EF H2.0 offers an additional advantage, as its glass fibres are less prominent on the surface. This ensures a high degree of tightness in the groove areas and improved removal from the mold.

During the development of the oil pans, Lanxess provided its partners with comprehensive support in the form of calculations and simulations. This included structural optimisation to improve the acoustic behavior of the pans, and a simulation exercise to examine resistance to stone chippings and deformation on exposure to sealing force. Simulations were also carried out for the filling of the injection molds and the distortion behavior of the oil pans. “These calculations helped us to ensure the molds were filled evenly, particularly in the flange area, thus minimising distortion,” explained Krause.

Other investigations examined how the oil pans would behave if the entire engine block, including the transmission, was removed and set down for maintenance work or repairs. In this instance, the pans would have to bear a weight of around 1.6 metric tons. Integral simulation was used to provide detailed analysis of the directionality of the thermal expansion around the flanges resulting from the varying fiber orientation in the component. “We used this to derive measures to ensure the tightness of the flange under all the potential temperatures and pressures,” said Krause.

As regards the Indian prospective, Sushmita Datta - Business Unit Head (India), High Performance Materials, said, “The commercial vehicle market is changing rapidly in India and there is a visible difference in the technology used in the past to those being used in the present. Commercial vehicles have evolved to be more advanced in terms of technology, enhanced quality and performance. Understanding the growth potential of the commercial vehicle industry, many multinational companies like Volvo, Daimler, Scania and MAN are very active and taking the opportunity to tap the potential and establish their market position in India. Such demand will certainly result in an increase in demand for high performance materials and their applications for the commercial vehicle sector."

Photograph: The oil pan for the 12.8-litre engine holds 36 litres of oil and is made of the polyamide 66 Durethan AKV 35 H2.0.

RELATED ARTICLES

Nissan shows in-construction all-solid-state battery pilot line in Japan

Under the Nissan Ambition 2030 long-term vision, Nissan aims to launch EVs equipped with the batteries by fiscal year 20...

BMW Group sells 82,700 BEVs in Q1 2024, sees growth across all key markets

The company has delivered a total of 82,700 fully-electric BMW, Mini and Rolls-Royce vehicles to customers worldwide, up...

Lanxess and IBU-tec to develop iron oxides for LFP EV batteries

Collaboration aims to improve performance of LFP cathode material; reduced carbon footprint of batteries through use of ...

28 Apr 2014

28 Apr 2014

3453 Views

3453 Views

Autocar Pro News Desk

Autocar Pro News Desk