Lanxess and Hella develop new PBT compound for battery components in EVs

The new compound christened Pocan AF4130 offers extremely low warpage and in particular high flame retardance.

German specialty chemicals company Lanxess has developed a new compound called Pocan AF4130 in collaboration with Hella KGaA Hueck & Co., based in Lippstadt, Germany. The new compound serves as a housing material for a battery management unit (BMU) and two-cell monitoring units (CMU).

The blend of polybutylene terephthalate (PBT) and acrylic ester-styrene-acrylonitrile (ASA) contains 30 percent by weight glass fibers and a halogen-based flame retardance package. “The particular advantages of the material are its extremely low warpage and shrinkage, combined with its high flame retardance. We see great potential for application in precision components for vehicle battery systems,” said Marc Marbach, head of Sales Segments E&E in the LANXESS High Performance Materials (HPM) business unit.

Lanxess states it took just two-and-a-half years to develop the compound, from the initial idea to extensive testing and finally to use in full-scale production.

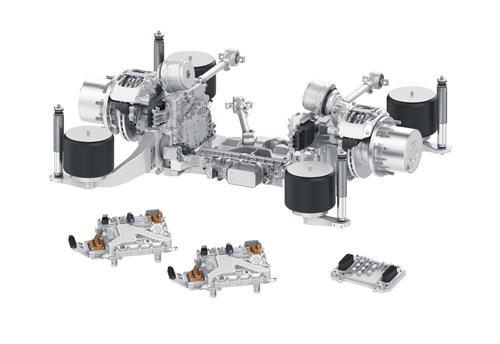

Hella fabricates the BMU and CMUs for a German manufacturer of battery systems for motor vehicles. The flat devices are currently used in the lithium-ion battery system of a German compact car.

Low tolerances

The housings of the BMU and CMUs have large, flat surfaces as well as complex geometries along the edges and on the inside. Because of its innovative design it can be injection-molded cost-effectively as single components. The contact pins for the connectors must not bend when the housings are mounted on the printed circuit boards. The tolerances for the spacing between the connector mounts and the cut-outs for the pins are therefore extremely close. “This is precisely where the outstanding dimensional stability of our blend Pocan AF4130 pays off,” explained Marbach.

UL 94 5VA- and UL f1-listed

As required for the application, the company claims that the material achieves the best classification of V-0 (0.75 millimeters) in UL 94 fire testing by the US testing organisation Underwriters Laboratories. It further is listed on the UL Yellow Card with a good classification of UL 94 5VA (1.5 millimeters). The material is aimed for injection molding of flame-retardant housing components. It additionally has been given a UL f1 listing for use in outdoor applications involving exposure to UV light and water. “Our compound thus has a good chance of also being used for electrical components such as photovoltaic plugs and sockets,” said Marbach.

The company states that the blend offers high resistance to typical media used in motor vehicles, such as fuels, oils, cleansers and car care products. And has been proven in extensive media storage tests conducted by Lanxess for Hella, in accordance with the supply specification LV 124 used by automotive manufacturers.

RELATED ARTICLES

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

Netradyne expands UK operations via partnership with Intelex

The collaboration between Netradyne and Intelex marks a substantial leap forward in advancing road safety and fleet mana...

By Autocar Pro News Desk

By Autocar Pro News Desk

14 Jun 2018

14 Jun 2018

8213 Views

8213 Views