Honda begins production at new plant in Mexico

Honda has started manufacturing the 2015 Honda Fit (Jazz) at a new, technologically-advanced automobile plant of Honda de Mexico, S.A. de C.V. (HDM).

Honda has started manufacturing the 2015 Honda Fit (Jazz) at a new, technologically-advanced automobile plant of Honda de Mexico, S.A. de C.V. (HDM). The new plant will increase Honda’s ability to meet customer demand for fuel-efficient subcompact models from within the North American region.

The start-up of the Celaya plant increases the carmaker’s annual automobile production capacity in North America to approximately 1.92 million units. In 2013, more than 90 per cent of the Honda and Acura automobiles sold in the U.S. were produced in North America; this is expected to exceed 95 per cent when the Celaya plant reaches full capacity.

Located in Celaya, Guanajuato, the US 800 million (Rs 4,966 crore) plant began production less than two years after construction started in early 2012, and will employ 3,200 associates with an annual capacity of 200,000 vehicles and engines when it reaches full production later this year.

In addition to the 2015 Honda Fit, the plant will begin production of an all-new compact SUV, later this year.

“Our new plant in Mexico is based on the Honda Company Principle of maintaining a global viewpoint to supply products of the highest quality, yet at a reasonable price, for worldwide customer satisfaction,” said Honda’s president and CEO, Takanobu Ito.

The Celaya plant, designed exclusively for the production of subcompact vehicles, features a number of Honda’s most advanced manufacturing technologies in the world, including several that were first introduced last year at Honda’s new Yorii Plant in Japan, to increase quality and efficiency and reduce the plant’s environmental footprint.

Key technologies include:

- A high-speed servo stamping press and adoption of a high-speed die change process that increases the efficiency of the stamping process by approximately 40 percent.

- An all-new, highly efficient general welder system, which joins the vehicle body panels together, achieves a major reduction in the number of welding robots, while increasing the number of weld points for higher quality and efficiency.

- A new 3-coat/2-bake, water-based painting process (replacing the traditional 4-coat/3-bake process) to reduce energy consumption during the painting process by approximately 40 per cent, while enhancing paint finish quality.

- A highly efficient production line intended to reduce the time and space for assembly processes, that includes a reduction in heavy-lifting processes for improved associate ergonomics, an increase of in-plant sub-assembly processes and new strategies that ensure both more efficient and more precise vehicle assembly.

- LED lighting was installed throughout the plant to reduce energy usage.

In addition, a new US 470 million (Rs 2,917 crore) transmission plant in Celaya is expected to begin production of continuously variable transmissions (CVT) in the second half of 2015, with employment of approximately 1,500 associates.

RELATED ARTICLES

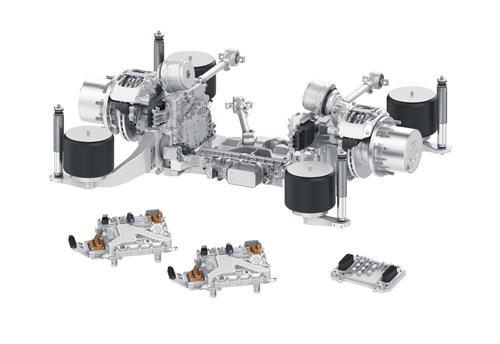

ZF to display next-gen e-axle for low-floor city buses at Busworld Turkiye 2024

The AxTrax 2 LF is available with a continuous output of up to 360 kW and a peak torque of up to 37,300 Nm.

Daimler Buses and BMZ Poland to develop next-gen NMC4 electric bus batteries

The new battery generation NMC4 – succeeding the current NMC3 technology – will combine high energy density, resulting i...

Netradyne expands UK operations via partnership with Intelex

The collaboration between Netradyne and Intelex marks a substantial leap forward in advancing road safety and fleet mana...

01 Mar 2014

01 Mar 2014

3094 Views

3094 Views

Autocar Pro News Desk

Autocar Pro News Desk