GKN and Chinese JV partner begin production of AWD Disconnect system for Jeep Renegade

The Disconnect function helps vehicles combine AWD's enhanced traction, dynamics and stability with improved fuel efficiency. It reacts to driver inputs and road conditions to seamlessly switch between 2WD and 4WD.

GKN Driveline’s Chinese joint venture partner SDS has commenced production of its complete all-wheel drive (AWD) Disconnect system for small to medium-sized vehicles in China.

GKN’s Disconnect function enables vehicles to combine the enhanced traction, dynamics and stability of all-wheel drive with improved on-highway fuel efficiency. The system reacts to driver inputs and road conditions to seamlessly switch between two-wheel drive and all-wheel drive.

During steady state cruising, the clutch system disengages the rear section of the driveline, eliminating rotating losses and improves highway fuel economy by up to 4% – compared to standard AWD. If the driver or conditions require more traction, the system reconnects within just 300 milliseconds.

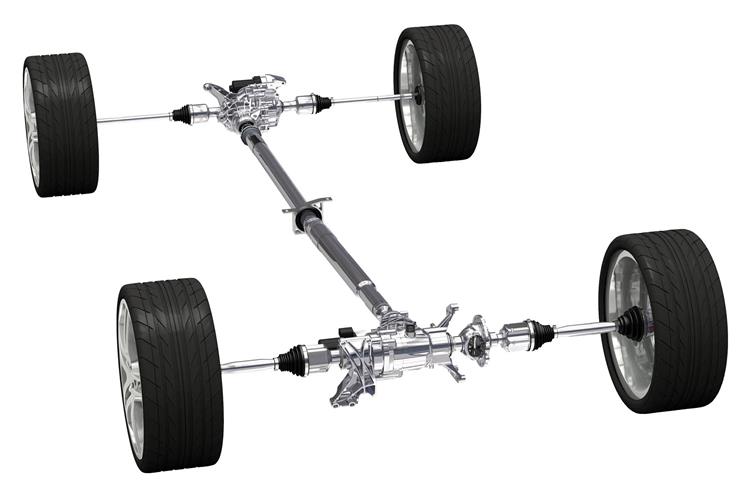

The system will initially feature on the Jeep Renegade built for the Chinese market by GAC Fiat Chrysler Automobiles Co (GAC FCA) in Guangzhou City, southern Guangdong Province. GKN’s Chinese JV, Shanghai GKN HUAYU Driveline Systems (SDS), will supply GAC FCA from its production facility in Shanghai. GKN manufactures the complete all-wheel drive system, including the power transfer unit (PTU), rear drive module (RDM), propshaft and sideshafts, as well as supplying software controls.

The move marks another milestone in the growth of GKN’s AWD business in China. SDS successfully localised production of PTUs and RDMs for Jaguar Land Rover models in 2015, including the Range Rover Evoque and Land Rover Discovery Sport, as well as localising production for two further automakers last year. More localisation programmes are due to start production for a range of manufacturers over the next two years.

SDS added six new AWD assembly lines and a new hypoid gear production line across two of its facilities in Shanghai during the past 18 months, as well as testing and other equipment, to support growing levels of business. The investment significantly expanded the company’s AWD production capacity in China.

Phil Swash, CEO, GKN Driveline, said: “GKN has capabilities to manufacture sophisticated all-wheel drive systems on a global basis and that’s why automakers choose to partner with us on their mega-platforms. The demand for all-wheel drive vehicles is growing at a rapid rate in China and GKN and SDS have a number of localisation and domestic programmes in the pipeline for the coming years.”

GKN’s scalable AWD Disconnect system was first launched on the Jeep Renegade and Fiat 500X subcompact crossover SUVs. As well as China, GKN builds the system at facilities in Europe and North America, and supplies the system in India and South America.

RELATED ARTICLES

Ramkrishna Forgings to supply powertrain parts to USA’s largest electric carmaker

Indian manufacturer of rolled, forged and machined products marks its debut in the US electric vehicle market.

Hyundai and carbon fibre specialist Toray to develop lightweight, high-strength materials

Partnership aims to secure capabilities to develop lightweight and high-strength materials for environmentally friendly ...

Yamaha wins Red Dot product design awards for MT-09 and XMAX 300

The latest awards mark the 13th year in a row – every year since 2012 – that a Yamaha Motor product has received a Red D...

By Autocar Pro News Desk

By Autocar Pro News Desk

16 Feb 2017

16 Feb 2017

6352 Views

6352 Views