Covestro and Leister introduce laser welding solutions for electric vehicle battery enclosures

Laser welding technique can include opaque flame-retardent blend for flame retardant plastic-based battery enclosures.

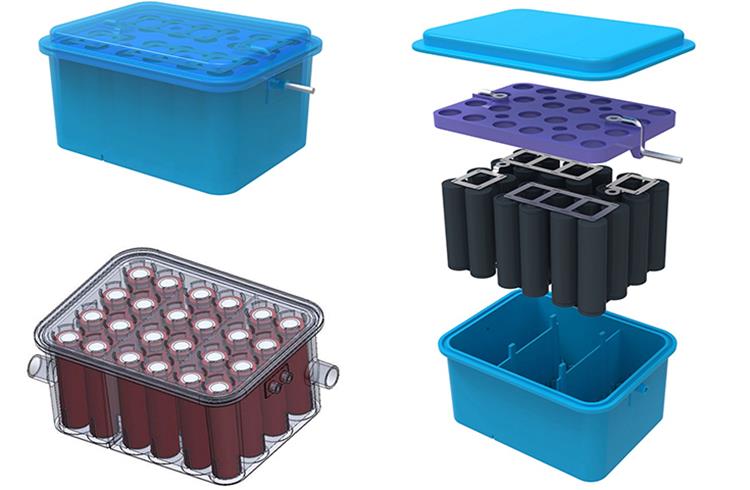

Germany-based Covestro and Leister Technologies have developed a process and material solutions for laser welding fluid-cooled battery modules used in electric vehicles such as new passenger vehicles, electric buses, trucks and other utility vehicles.

Batteries used in electric vehicles must be actively cooled to function properly and retain their lifespan. This process, known as fluid cooling, requires airtight seals to keep fluids contained and avoid spills. While several joining methods can be used to weld plastic battery packaging components, those that do not require external agents are less complex and more cost-efficient. Of these techniques, manufacturers often turn to laser welding as it allows for larger parts, does not require a pre-treatment and offers high-precision, repeatability and control.

Fernando Santillana, senior project manager – Midwest, East Coast, Caribbean and Latin America, Leister Technologies said, “This joining technique provides the accuracy needed for welding in tight locations and around other components in fluid-cooled systems.”

Laser welding is traditionally only used with translucent or optically clear plastics. Now, however, Covestro and Leister Technologies have extended use of this joining technique to include opaque flame-retardant Bayblend PC+ABS blend from Covestro, while achieving the same level of weld strength. Flame-retardant plastics are preferred and often required for battery enclosures as they can help prevent or delay the spread of fires.

Terry Davis, principal engineer, Covestro said, “Using Bayblend FR3010 PC+ABS blend, we developed effective and reliable laser welding solutions for production-ready battery modules that can withstand battery abuse testing, including UN38.3. With this material, battery manufacturers can create reliable and leak-free battery enclosures.”

According to Covestro, naturally opaque Bayblend FR3010 PC+ABS blend features a variety of benefits, including high-impact strength, chemical and hydrolysis resistance, thermal stability, and a good balance of high-heat distortion and physical performance.

RELATED ARTICLES

Marelli Talbros Chassis Systems wins Rs 1,000 crore business from European OEM

The order, to be executed over an eight-year period, is for the supply suspension arms tailored for both conventional in...

Kia launches customised NBA display themes for North American market

Display Themes is a customised service that supports a personalised vehicle experience, allowing users to customise the ...

Antolin and VIA Optronics unveil versatile vehicle cockpit concept

The Sunrise vehicle concept cockpit, which is engineered for seamless transitions between manual and autonomous driving ...

By Autocar Pro News Desk

By Autocar Pro News Desk

12 Sep 2018

12 Sep 2018

4752 Views

4752 Views