Continental’s new lightweight turbo enters series production

Global automotive supplier Continental’s new turbocharger with water-cooled aluminium turbine housing has entered series production in the three-cylinder petrol engine of the Mini hatchback.

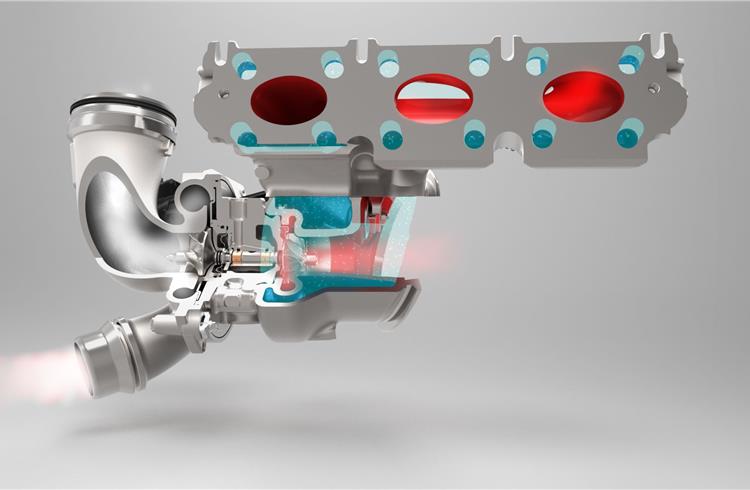

Global automotive supplier Continental’s new turbocharger with water-cooled aluminium turbine housing has entered series production in the three-cylinder petrol engine of the Mini hatchback. This turbocharger is the first of its kind worldwide to be used in a car and enables a significant weight reduction of nearly 30 percent (1.2kg) while also providing cost and system benefits.

As vehicle manufacturers worldwide look for smaller cubic capacity and lower fuel consumption while offering the same, if not better, performance, they are opting for modern turbocharged systems. This has led to the global development trend toward turbocharging for petrol engines. Continental says its first turbocharger went into series production in a highly efficient, multi-award-winning 1.0-litre engine in 2011.

"Aluminium in a turbocharger designed for cars is a real milestone," says Wolfgang Breuer, head of the Engine Systems Business Unit of the Powertrain Division. "With this lightweight material, we are saving nearly 30 percent of weight compared to a conventional turbocharger while simultaneously reducing costs and achieving system benefits."

The innovative turbocharger with aluminium turbine housing is making its debut in a demanding downsizing application: a turbocharged three-cylinder engine with 1.5 litres of cubic capacity and 100kW of power.

"It's not just the aluminium that makes the turbocharger special; it was also developed from being a typical add-on component to an integral part of the engine," explains Udo Schwerdel, head of the Turbocharger Product Line, Engine Systems, Powertrain Division. "In order to meet the requirements placed on the unit and its integration in the cylinder head, we worked closely with the BMW Group starting from the simulation phase – an indication of trust that we greatly appreciate."

There were development challenges though. Full-load operation can be enough to make common turbocharger constructions with a steel housing glow red all over, however, the aluminium turbine housing keeps a cool head.

"The double-walled aluminium housing surrounds the hottest area with a cooling water jacket," says Schwerdel. The coolant flowing through this jacket ensures that the external housing surface does not get hotter than 120deg C (248°F) and the internal temperature does not exceed 350deg C (662°F), which Udo Schwerdel explains has not one, but two benefits: "First, much less effort is required to protect neighboring components from the heat. Second, cooling of the exhaust flow reduces the thermal load on the catalytic converter, meaning it hardly ages at all." At the same time, the dynamic response of the electric actuator at the wastegate ensures that the catalytic converter heats up quickly.

In keeping with the modular principle given by the customer, the turbocharger is tightly integrated in the engine (it is a fixed component of the exhaust manifold), but Continental turbochargers with a steel housing can also be attached to the same base engine using the interface on the cylinder head. The car manufacturer is using this option for high-performance engines as well as vehicles for export to hot countries. The bearing housing is cooled from inside the turbocharger for steel variants, while cooling from outside is sufficient for aluminum turbochargers.

In the Mini, 1.2kg of weight is saved per aluminium turbocharger. Since reduced weight also means reduced fuel consumption, the lightweight material supports the fuel consumption and emission targets of the automotive industry. Despite the additional expenditure for the water cooling, aluminium turbochargers are more affordable for automotive manufacturers.

"High-temperature-resistant materials such as nickel-base alloys drive up prices for turbochargers with steel housings," says Schwerdel, "whereas our aluminum alloy is a cost-effective material."

RELATED ARTICLES

Marelli Talbros Chassis Systems wins Rs 1,000 crore business from European OEM

The order, to be executed over an eight-year period, is for the supply suspension arms tailored for both conventional in...

Kia launches customised NBA display themes for North American market

Display Themes is a customised service that supports a personalised vehicle experience, allowing users to customise the ...

Antolin and VIA Optronics unveil versatile vehicle cockpit concept

The Sunrise vehicle concept cockpit, which is engineered for seamless transitions between manual and autonomous driving ...

15 Jul 2014

15 Jul 2014

4422 Views

4422 Views

Autocar Pro News Desk

Autocar Pro News Desk