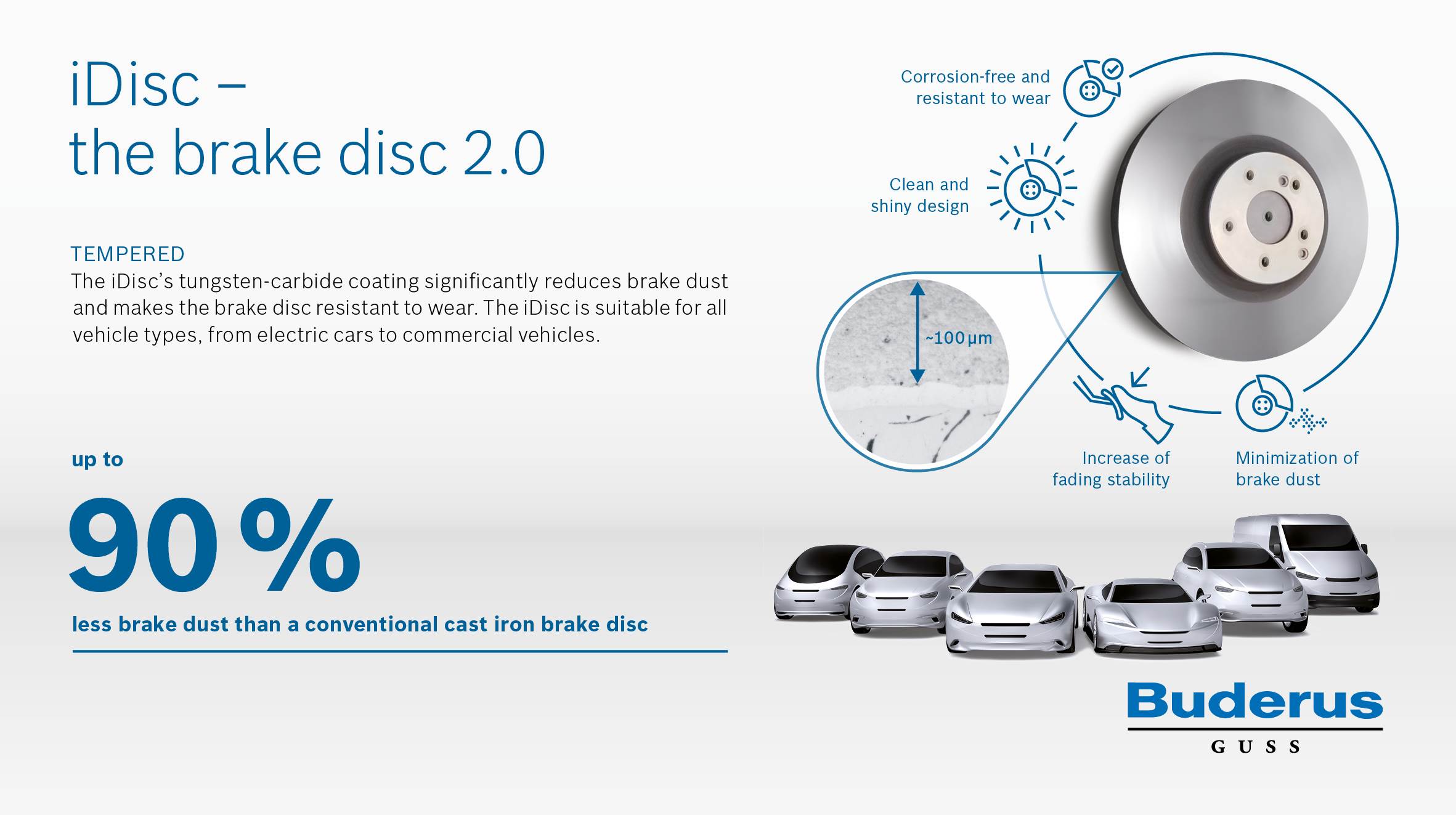

New brake disc tech claims to reduce 90% brake dust

New Buderus Guss brake disc generates up to 90 percent less brake dust. iDisc’s carbide coating reduces brake wear and tear while enhancing operating safety.

Components and technology major Bosch has said its subsidiary Buderus Guss has developed the new ‘iDisc’ brake disc that generates upto 90 percent less brake dust, making it an effective solution to reduce the growing particulate-emission problem in cities.

The company says that brakes and tyres are responsible for around 32 percent of driving-related particulate emissions, and its new iDisc with its carbide coating will reduce brake wear and tear while enhancing operating safety. It is scheduled to go into production for a European manufacturer in November 2017. Bosch estimates that the demand for car brake discs stood at more than 330 million units in 2016.

Bosch states that the brake disc has been at the centre of focus for making driving safer before the introduction of other key safety features — ABS, ESP, airbags, and other features. The brake disc which has made driving safer and significantly shortened stopping distances, thereby helping prevent many traffic accidents, today is at the centre of public attention for another reason: brake dust.

Most particulate pollution from road traffic is caused by road, tyre, and brake wear rather than fuel combustion. According to the Baden-Wurttemberg state environmental agency, brakes and tyres are responsible for 32 percent of driving-related particulate emissions, roughly half of which is brake dust. Significantly reducing brake dust is therefore essential to improving the air, especially in cities.

Bosch says the iDisc, compared to a conventional brake disc, generates up to 90 percent less brake dust. “It’s not just under the hood that Bosch is working to keep the air clean, the iDisc is the brake disc 2.0. Its market potential is tremendous,” says Dr. Dirk Hoheisel, whose areas of responsibility on the Bosch board of management include Buderus Guss.

iDisc

According to the company, the iDisc (the 'i' stands for innovation) is a tungsten-carbide coating that is currently only available from Buderus Guss. The technology is based on a conventional cast iron brake disc. Every year, the subsidiary produces up to 20 million of these discs at its German locations in Breidenbach and Ludwigshutte. To transform a conventional disc into an iDisc, the friction rings are mechanically, thermally, and galvanically treated before being coated. All this is part of a process developed by Buderus Guss and Bosch researchers over a period of many years.

In terms of price, the iDisc is roughly three times more expensive than a normal cast iron brake disc, and three times less expensive than a ceramic brake disc. The price is likely to continue falling as production volume increases.

“The iDisc has everything it takes to replace the conventional cast iron brake disc and become the new standard in the brake disc market,” says Gerhard Pfeifer, managing director of Buderus Guss.

“Given the continued particulate pollution debate in many countries and large cities around the world, there is nothing standing in the way of its breakthrough,” Pfeifer added. He states that brake discs will be needed in cars for decades to come, and production volumes are continuing to rise.

Another argument in favour of the iDisc is its many positive qualities. In addition to a dramatic reduction in brake dust, the carbide coating also ensures greater operating safety. The braking performance is similar to that of a ceramic brake, especially when it comes to fading, as the reduction in stopping power following repeated braking maneuvers is known.

Like a ceramic brake disc, the iDisc is highly stable in this respect and loses little deceleration performance. Wear is also significantly reduced. Depending on the strength of the carbide coating, the iDisc’s service life is twice that of a normal brake disc. Gouging marks on the friction ring? Not a chance, says Bosch.

Corrosion is also not an issue – a major advantage, especially in electric cars. Because they recover braking energy in a process known as recuperation, electric cars put less strain on the brakes and often have to contend with rust formation on friction rings. The temporary slight decline in responsiveness during braking associated with this does not occur with the iDisc.

RELATED ARTICLES

Hyundai and carbon fibre specialist Toray to develop lightweight, high-strength materials

Partnership aims to secure capabilities to develop lightweight and high-strength materials for environmentally friendly ...

Yamaha wins Red Dot product design awards for MT-09 and XMAX 300

The latest awards mark the 13th year in a row – every year since 2012 – that a Yamaha Motor product has received a Red D...

Honda reveals new Ye series of EVs for China

A second set of Ye EVs will be revealed in the coming months, completing the six-car line-up for China.

By Autocar Pro News Desk

By Autocar Pro News Desk

24 Nov 2017

24 Nov 2017

5663 Views

5663 Views