Bosch suggestions scheme turns 90, saves over Rs 3,000 crore over 10 years

German component major Bosch, for 90 years now, has systematically benefited from its associates' creativity and innovative spirit.

German component major Bosch, for 90 years now, has systematically benefited from its associates' creativity and innovative spirit. In the past 10 years in Germany alone, the company has saved some 395 million euros (Rs 3,027 crore) thanks to suggestions for improvement made by its associates.

Last year, the global supplier of technology and services paid out 7.7 million euros (Rs 59 crore) to associates at locations across Germany in reward for their ideas, which had saved Bosch some 33 million euros (Rs 253 crore). In total, a good 21,900 associates submitted their suggestions, an increase of 2.4 percent over the previous year.

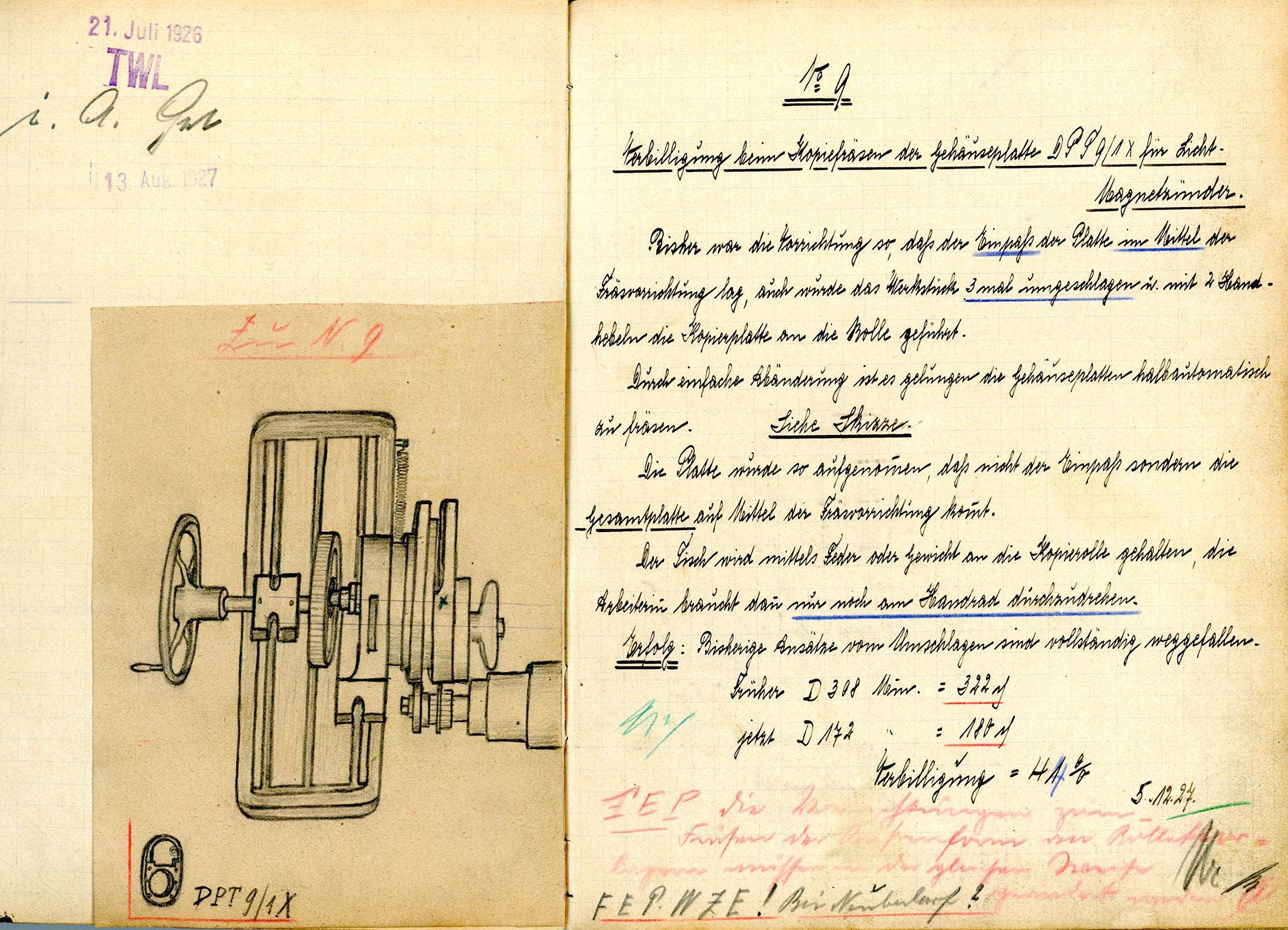

In 1924, company founder Robert Bosch announced the launch of a company suggestions book (depicted below).

In so doing, he laid the foundation stone for what has since become a global ideas management program. His aim was to “perfect work processes and improve products, or reduce the cost of producing and managing them.” Bosch recently received the 2014 DeutschenIdeenPreis (German idea prize) for the best ideas management program in the automotive supplier category.

“The creativity of our associates continues to fuel our innovative strength,” said Christoph Kübel, member of the board of management and director of industrial relations at Robert Bosch GmbH, on the occasion of the anniversary. “The experience, creativity, and proactive thinking of each associate makes us more competitive and leads to better products. Often, small ideas that are beyond the scope of everyday tasks can make a big difference,” Kübel said. According to Kübel, such ideas are also the product of a working culture that values cultural diversity and promotes creativity.

Ideas management: more than making suggestions

At Bosch, associates at every location are encouraged to submit suggestions for improvement. Ideas can include, for instance, ways of optimizing operations, improving product quality, avoiding waste, or promoting environmental protection. Associates are also encouraged to submit ideas that may even go beyond their direct areas of responsibility. If an improvement is implemented and results in cost savings, the associates concerned are given a cash reward of up to 150,000 euros (Rs 1.5 crore). In addition to this company suggestion scheme, Bosch also relies on systematic ideas generation. “We don't just submit suggestions, but also generate ideas,” said Peter Schmid, who is charge of the Bosch Group's ideas management program. “For example, coordinators attend workshops to learn how they can use creativity techniques to actively support associates at their locations. Knowledge platforms, advisory services, networks, workshops, and further training can contribute to continuous improvement.” Associates can even train to become ‘Bosch Innovation Agents’.

Clever ideas – making clogged pipes a thing of the past

Two associates at the Bosch site in Lohr, Germany, received the highest possible cash prize of 150,000 euros. Ferdinand Schneider and Xhafer Istrefi, who work at a foundry of the Bosch Drive and Control Technology division, came up with an inexpensive way to clean pipes through which molten steel flows: they use oxygen. “In the past, clogged pipes resulted in frequent down-time, and there were often delays before the next processing steps could take place,” Schneider says. The two associates went ahead and improved the process, without thinking of a potential cash reward. “We didn't submit our idea as a suggestion for improvement until we noticed while testing it out that production numbers had improved,” Istrefi says.

U.S. plant in Charleston: leading the field in ideas management

The suggestions scheme that the company founder Robert Bosch introduced in Germany is now part of a comprehensive ideas management program. Designing and implementing customized idea generation shapes the basis of innovation. Today, Bosch ideas management is successful around the world. The program comprises a network of more than 60 coordinators, who support Bosch locations in systematically coming up with ideas for improvements. This is in addition to the ideas that associates come up with by chance. The Charleston location in the United States has been especially successful of late. HR boss Kübel described the plant as having by far the best ideas management. In Germany, the Ansbach plant leads the field.

Standardised ideas management around the world

In the future, ideas management around the world will be even simpler. Many associates can already submit ideas electronically, and now the different IT systems used at Bosch locations in Germany and beyond are set to be standardized. At the Jaipur site in India, for instance, an online system has already been introduced. At easily accessible terminals, each associate can see whether or not their supervisor has already looked at their idea, and whether it has already been put into practice. At Bosch, today's ideas management program reflects the words of Robert Bosch, which continue to inspire associates around the world: “We should all strive to improve on the status quo: none of us should ever be satisfied with what they have achieved, but should always endeavor to get better.”

Photograph: The idea that Bosch associates Xhafer Istrefi and Ferdinand Schneider came up with ensures the cleaner, more even flow of molten iron in the foundry. In the past, workflows had to be interrupted on a regular basis in order to remove residue from the opening through which the molten metal flowed. Since 1924, Bosch has systematically encouraged its associates to suggest improvements to work processes. The photo shows Istrefi and Schneider at their furnace workstation.

RELATED ARTICLES

Kia displays EV5 and Sonet SUVs for Chinese market

Kia has unveiled a number of key models and new technologies for Chinese customers at the 2024 Beijing International Aut...

Nissan targets growth in China, unveils four NEV concepts at Beijing Motor Show

The two EVs and two plug-in hybrids are a joint effort with Nissan’s local partner Dong Feng and aimed to better address...

Lamborghini unveils Urus SE ahead of Auto China 2024

Electric-only range of 60km helps reduce emissions by 80%.

By Autocar Pro News Desk

By Autocar Pro News Desk

25 Nov 2014

25 Nov 2014

5225 Views

5225 Views