BorgWarner launches software tool to optimise supplier performance

BorgWarner has introduced software that constantly monitors its supply chain to significantly improve delivery, reduce risk and simplify processes.

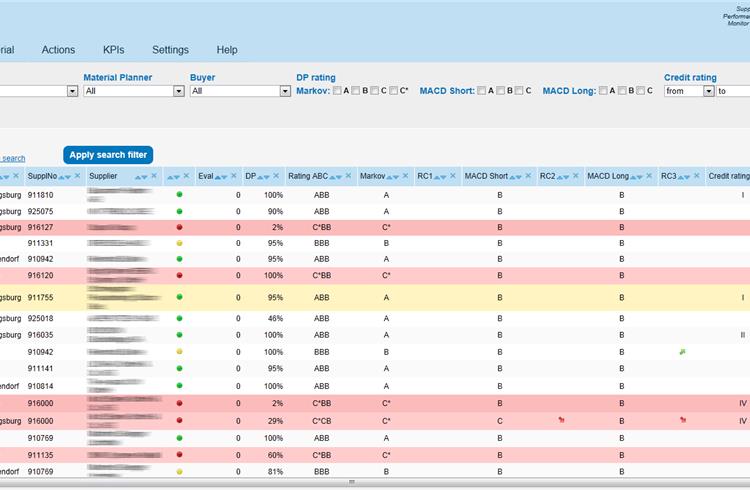

BorgWarner has introduced software that constantly monitors its supply chain to significantly improve delivery, reduce risk and simplify processes. The first to apply artificial intelligence and sophisticated mathematical theories to analyse current supplier performance and forecast future trends, BorgWarner’s Supplier Performance Monitor (SPM) system constantly monitors the supply chain, allowing suppliers and customers to jointly identify and manage problems at an early stage.

The SPM system uses artificial intelligence and sophisticated mathematical theories to analyze current supplier performance and forecast future trends. The easy-to-install software can be transferred to new locations and improves supply chain response times significantly.

Originally launched in Germany and Ireland, BorgWarner intends to implement the user-friendly software in the United States and other parts of Europe beginning in early 2014, followed by India and China later this year. BorgWarner’s SPM system has been awarded several honours such as the Supply Chain Innovation Award 2012 and the VDA (German Automotive Industry Association) Logistics Award 2013.

“BorgWarner’s Supplier Performance Monitor system analyzes actual data on quantity and delivery reliability, and significantly simplifies processes,” said Brady Ericson, president and general manager, BorgWarner BERU Systems. “We have received fantastic feedback from our suppliers on this ground-breaking innovation. The SPM system helps us jointly identify problems and proactively manage situations at an early stage.”

To accommodate the dynamic global economy where suppliers must work in close partnership with their customers throughout the supply chain, BorgWarner developed the SPM system to optimise its supplier network as well as its own performance. Based on the stochastic Hidden Markov Model, the software tool uses artificial intelligence and probability methods to evaluate existing mass data from enterprise resource planning (ERP) systems including data on orders, deliveries and cancellations as well as master, financial and quality data. Users receive information on past, current and future performance as well as the status of specific measures and indicators.

BorgWarner’s SPM system improves collaboration between all supply chain functions by involving all suppliers, revealing potential risks early. More than 90 percent of BorgWarner BERU Systems’ suppliers currently participate in the SPM system, which has optimised delivery performance and reduced delivery times by 60 percent. In addition, BorgWarner BERU Systems achieved a 33 percent drop in parts failure (PPM) from suppliers in 2012 compared with the previous year.

RELATED ARTICLES

Nissan shows in-construction all-solid-state battery pilot line in Japan

Under the Nissan Ambition 2030 long-term vision, Nissan aims to launch EVs equipped with the batteries by fiscal year 20...

BMW Group sells 82,700 BEVs in Q1 2024, sees growth across all key markets

The company has delivered a total of 82,700 fully-electric BMW, Mini and Rolls-Royce vehicles to customers worldwide, up...

Lanxess and IBU-tec to develop iron oxides for LFP EV batteries

Collaboration aims to improve performance of LFP cathode material; reduced carbon footprint of batteries through use of ...

13 Mar 2014

13 Mar 2014

3945 Views

3945 Views

Autocar Pro News Desk

Autocar Pro News Desk