'India's auto electronic systems market is set to grow at a CAGR of 11-14% till 2022.'

Rajesh Kulkarni, VP – sales and marketing – Hella India Automotive, on the growing demand for auto electronics and the growing scale of the Pune-based R&D centre's contribution to Hella’s global network.

In a recent conversation with Autocar Professional, Rajesh Kulkarni, VP – sales and marketing – Hella India Automotive, revealed his company’s outlook on the growing demand for auto electronics. He also highlights the relevance of HIA’s Pune-based R&D centre and its contribution to Hella’s global network. Gearing up to meet requirements around electric mobility in the future, the centre is working to build competencies around energy management products. Excerpts:

Can you tell us how the Pune R&D centre has grown over the past nine years. In terms of R&D support, where does this centre stand within Hella’s electronics division?

When Hella India Automotive Electronics Development Centre (HIA-ED) started its operations, it was only providing design and development support for global projects.

The strategy was to build competence in domains where Indian talent could be utilised for providing support on global projects, which could be further utilised for executing local projects. Over the period, HIA-ED developed expertise and became capable of handling independent development for body electronics (independent designing of body control modules and remote key less entry system with business award from Tata Motors).

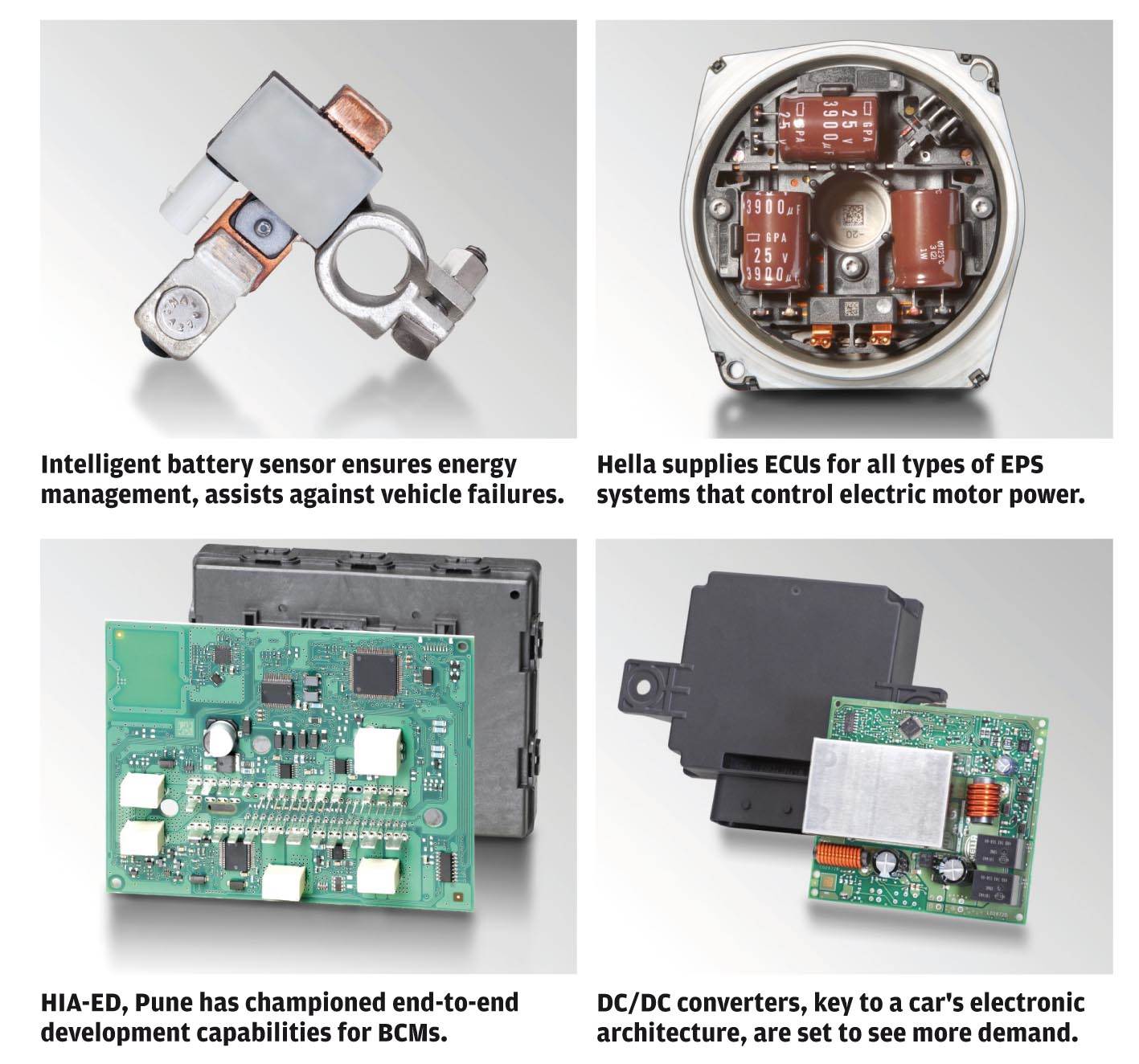

HIA-ED has a major contribution to establish Hella India Automotive (HIA) as an important electronics supplier for Indian automotive industry. As of today, this centre’s major achievements and technical competencies include:

- Complete product development capability of complex electronics.

- Complex BCM development in AUTOSAR and MATLAB environment.

- Acquisition of local programs for BCM, RKE, DC/DC converter, electrical power steering (EPS), smart mood lighting (SML) and their execution.

- Centre of competency for two-wheeler/three-wheeler products.

- Power electronics, D&D capability for DC/DC converter, battery charger, motor controller and EPS.

- Platform development for BCM/CCM (comfort control modules).

- Highly automated hardware in loop test system.

- Advance engineering in the areas of e-mobility and connectivity.

HIA-ED is one of the key design and development centres in the global Hella network. Similar competency is being developed for energy management products also.

What are the new technologies and products that the Pune-based R&D centre is working upon?

Today’s need is to address global and local industry trends by rolling out cost-efficient electronic systems that will increase personalisation, digitisation and boost fuel efficiency. New products which are being developed at HIA-ED are perfectly tuned to cater to these requirements.

Currently, HIA-ED is working on some interesting technologies and products, which are – smart mood lighting (SML), steering control module (SCM), commercial vehicle body control modules (CV BCMs), current sensor, DC/DC converter, tyre pressure monitoring system (TPMS) and Reverse Park Assist System (RPAS).

Smart Mood Lighting (SML): Hella’s SML is an innovative way of controlling vehicle ambient lighting through a smartphone. SML gives a personalised look to the car interior by changing the lighting colour based on the occupant’s mood and speed zone. The Tata Hexa features this unique product from HIA.

Electric Power Steering: Hella offers modular EPS solutions with steering control module and torque and angle sensor based on Hella’s proprietary CIPOS technology. The motor is only powered when assistance is required. This saves energy and results in fuel mileage improvement. Production of EPS is expected to start soon for an off-highway vehicle.

Current sensor: Hella’s battery current and temperature sensor offers a low-cost alternative to the intelligent battery sensor (IBS) by providing battery current and temperature to external ECUs such as body controller or engine management system to implement required algorithms like SOC, SOH and SOF.

DC/DC converter: Micro and mild-hybrid vehicles fitted with start-stop and coasting functions require regulating the power flow of the generator, the electric loads and the energy storage system. The use of DC/DC converter in vehicle electric power systems enables such applications. High-power 48V to 12V DC/DC converters support features like boosting and creeping. Last year, HIA won a business for DC/DC from a major CV maker. The product will be exported as well after being supplied in the local market.

Tyre pressure monitoring system (TPMS): Hella’s unique TPMS provides live display of air pressure of tyres and temperature on a smartphone. It maintains tyre pressure within prescribed limits, and thus reduces fuel consumption. It eliminates the need of receiver ECU and complex learning mechanism.

At HIA-ED all the products are designed and developed following rigorous advanced product quality planning (APQP) process, which is fully compliant with ISO/TS16949, VDA Band 6, ISO 26262, Automotive SPICE.

Reverse Park Assist System (RPAS): The function of RPAS is to alert the driver of obstacles at the rear of the vehicle. This system is activated in reverse gear and the driver gets an audible warning or visual display. The system is comprised of either sensors and control units only, or with cameras also.

How big is the automotive electronics market in India? How do you see the market for electronics within the automotive industry going forward?

The automotive electronics market in India has huge growth potential due to its low penetration currently. However, the Indian automotive market is witnessing three major trends i.e., regulatory norms, comfort and personalisation. The electronic content will see a major boost under these trends.

Going a little forward, the industry will see demand driven by trends i.e., regulatory norms, e-mobility and connectivity. Hella’s automotive electronics products are in consonance with these current trends and will keep evolving over the time.

As of 2017, as per the market trends, the OEMs are embracing TPMS, current sensor and DC/DC converters under new regulatory requirements. They also opted for BCM, CCM, RKE and CAPE under passenger comfort requirements and for SML under personalisation.

As of 2025, we believe that OEMs will continue to embrace technologies such as TPMS, current sensor, DC/DC converters besides opting for connectivity ECUs under vehicle connectivity requirements and IBS and DC/DC converters under electric mobility.

HIA-ED design and development activities are perfectly tuned to cater to the potential in these areas with the right tailored products and technologies.

What kind of growth rate in the demand for electronics and electric components is expected in India? How has the electronics division grown over the last few years, and what are your expectations from FY2017-18?

Since 2014, HIA’s electronic division has grown at a mid-double digit CAGR. The India market for automotive electronic systems is expected to grow at a CAGR of 11-14 percent till 2022. In general, HIA’s electronics sales are expected to grow in line with the market growth rate.

Current penetration of automotive electronics is limited in India. With the government norms on safety and efficiency coming into force, the automotive electronics will see a spike in demand. Thus, during FY 2017-18, HIA’s electronics business is expected to grow significantly above the market growth.

How do you assess the rise in demand for electrical parts such as sensors on the back of the incoming BS VI emission norms and mandatory safety norms?

India’s auto component makers are ready for a shift to BS VI emission norms, and so is Hella. Our core fuel efficient technology sensors like IBS, TPMS and steering sensors will help to a great extent for emission reduction.

- IBS allows precise battery monitoring and intelligent alternator control, which ensures engine cranking ability at all times, leads to fuel saving and CO2 reduction.

- Steering sensors will help to improve fuel mileage.

- TPMS ensures safety by providing alerts with respect to temperature and pressure of the inflated tyre. Also, it helps in reducing fuel consumption.

Other sensors in Hella’s global portfolio, which could help in emission and safety requirements, are:

Throttle position sensor (TPS): It helps in maintaining optimal fuel economy as it provides signals to fuel injection system about power demands made by engine. The sensor is installed in the throttle valve of the drive-by-wire system. With high temperature resistance, it provides precise position control.

Exhaust gas recirculation sensor: The exhaust gas recirculation sensor (EGR sensor) is used to measure the position of the exhaust gas valve, which regulates the flow of exhaust gas.

Oil pressure and temperature sensor: The sensor is used to measure the absolute oil pressure and temperature directly in the main oil channel behind the oil filter. The sensor enables oil pump control to reduce fuel consumption and CO2 emissions.

HIA will bring these products to India depending on the demand and business considerations.

What are the first customer requirements, as seen by HIA, under different incoming trends in the auto industry in the near future?

Hella products catering to the below mentioned trends are expected to see high demand from customers in near future:

Efficiency and Electrification: DC/DC Converters, Intelligent Battery Systems (IBS), motor controller and battery charger.

Connectivity and Digitalisation: Body Control Modules (BCMs), Car Access Passive Entry (CAPE), Remote Key Entry (RKE), Temperature sensors and Reverse Park Assist System.

Individualisation: Smart Mood Lighting (SML).

Autonomous Driving: Electric steering, steering sensors.

Which is the largest selling product within HIA’s current portfolio? Do you see this changing in the next few years?Currently within HIA’s electronics unit, the body control module (BCM) has the highest amount of sales and we expect the growth momentum to continue in the coming years also.

At the same time, we see that electronics sales will be highly contributed by new products like EPS, SML, CV BCM due to major order intake received for these products.

How big is the current manpower in Pune? Is the company planning to expand the same in future?

Current manpower in Pune is about 260 currently. The projected growth for HIA in terms of headcount in about 20 percent year-on-year.

Is the team working from Pune-based R&D centre developing or supporting global programs?

Yes, currently 70 percent of the work done in HIA-ED (Pune) is for supporting global programmes. The programmes supported include:

- Body products like body control modules, remote keyless entry, memory seat module.

- Energy management products like DC/DC converters.

- Electric power steering.

What are the other development capabilities of HIA-ED, Pune?

Some of the critical development capabilities of HIA-ED include:

- SW Development

- HW Development

- Mechanical Development

- System Test and Validation

- Instrumentation

- Calibration

- Test Equipment Build Up

RELATED ARTICLES

BRANDED CONTENT: 'We aspire to be among the leading sensors and electro-mechanical products manufacturer'

P. Parthasarathy, Founder & Managing Director, Rotary Electronics Pvt Ltd shares the company's commitment and vision to ...

‘Big opportunity for startups lies in products in India’: Detlev Reicheneder

As electrification levels the playing field, the focus on tech and R&D to bring innovative products is the mantra for st...

'I hope my journey makes people say — I can do this too'

Ranjita Ravi, Co-founder of Orxa Energies — the maker of Mantis e-bikes — shares the challenges of building a startup an...

By Amit Panday

By Amit Panday

05 Jan 2018

05 Jan 2018

29308 Views

29308 Views