Tata Motors brings JLR’s best practices with Zest

Though the Tata Motors and Jaguar Land Rover brands belong to two different worlds, Tata has adopted several processes to change the overall product development approach, says Sumantra B Barooah.

The just-launched Zest sedan marks a fresh innings for Tata Motors in the passenger vehicle market. Its efforts to introduce a good product proposition can be seen in various areas, be it on the design front or in the way the car drives. At the root of it all is an overhaul of the passenger vehicle business unit (PVBU).

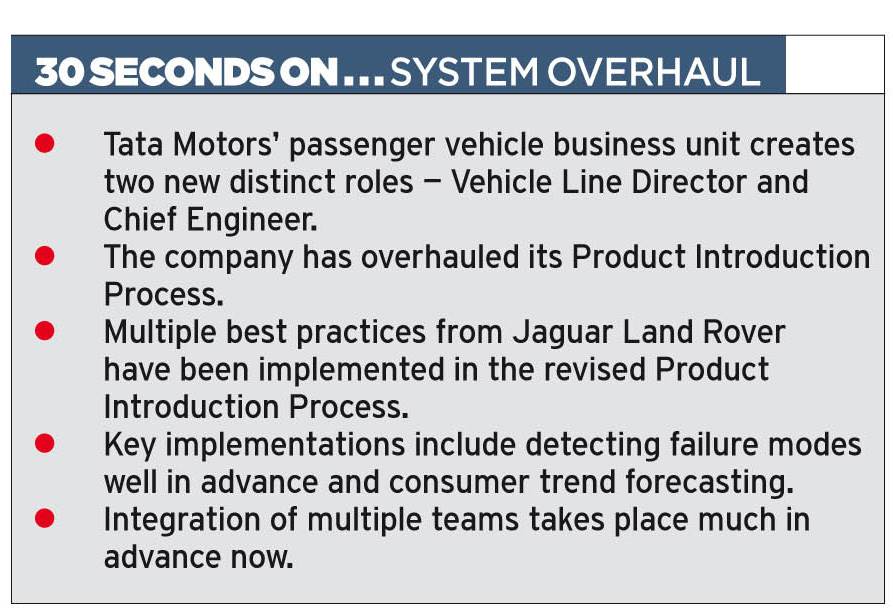

For starters, there has been a modification in organisational structure. Two positions – vehicle line director and chief engineer – have been created in the PVBU to ensure that cars being developed, and which is growing increasingly complex, and the collaboration with suppliers, is being done in a manner to give better results than before. “Both these positions have a very strong leadership role as well as integration role to be played in the entire programme,” explains Girish Wagh, head – Program Planning & Project Management (PVBU), Tata Motors, in an interview to Autocar Professional.

Under the Horizonext strategy, Tata Motors wants to be among the top three players in every market it is present in. That has required a lot of focus on processes in the entire cycle of conception to launch of a product, sales and aftermarket. On the processes front, it has picked up more than a leaf from Jaguar Land Rover’s (JLR) book. “We had a process in place but realised this process needs an overhaul,” says Wagh.

The internal product introduction process is the first where Tata Motors has implemented some best practices taken from JLR. For example, Tata Motors has one called market offers selection. Here, it creates multiple offers from a market positioning perspective and then compares them with what the company intends to do. Based on that comparison, it selects one particular marketing offer.

After that, the Tata team has introduced what it calls ‘product concept selection gateway’, which selects the best of the various proposed product concepts that meet the target audience’s requirements as well as the company’s business requirement. “Based on that, we select the right product concept. We have strengthened our processes upfront which ensures that by the time we kind of give clearance to this product concept for further development, we have a lot more confidence in what this product concept is going to do and the targets is it going to meet,” explains Wagh.

With this tweaking in the product development stage, the company can increase the chances of a product succeeding. What Tata Motors has also introduced is a ‘forward model quality’. This is also a learning taken from JLR, since British marques are “very strong” in this. It is learnt that JLR does continuous annual processes – attribute futuring, consumer trend forecasting, what is likely to happen, therefore what does a brand need to do in the segment, what should be its product and so on. Tata Motors has picked up many of these and aims to institutionalise it.

Another interesting process Tata Motors has taken is the forward model quality process. It essentially means detecting various failure modes well in advance and devising ways to pre-empt such problems. Suppose there is a failure mode of, say, deterioration in clutch life or deterioration in pedal effort is one failure mode. The team picks up the failure mode from some of Tata’s current products or the engineers also sit together and brainstorm on possible new failure modes. They identify all those failure modes and even before a product concept is finalised, the failure is pre-empted. This failure mode avoidance is something that Tata Motors has institutionalised as part of forward model quality. This, therefore, improves product reliability and reduces the dependence on physical validation.

In addition to that, Tata Motors has institutionalised a launch process. This initiative has a dedicated launch team headed by a manager from the plant who reports to the plant head and the vehicle line director. This person has a dedicated cross-functional team. They are nominated quite early on in the programme, even before validation is completed. “They pick up the product from there and start looking at it from a productionisation and quality maturation point of view. They begin giving inputs and in a way pull the product into the plant. These, among other interventions, ensure that we improve on our delivery capability,” says Wagh.

The process overhaul is done not only for better internal efficiency but also with suppliers. With significant interventions in the overall product planning, development and production process, Tata Motors is bullish about its future in the passenger vehicle market, not only in India but in multiple markets across the world. The Zest represents the first step in this new journey.

Also read: Interview with Tata Motors’s Girish Wagh http://t.co/Gc3Z5nZwcB

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

14 Aug 2014

14 Aug 2014

7753 Views

7753 Views

Autocar Pro News Desk

Autocar Pro News Desk