MagneRide suspension: Design, development and applications

MagneRide is not a name most drivers will be familiar with, but it’s a technology many will use daily.

MagneRide is not a name most drivers will be familiar with, but it’s a technology many will use daily.

It's a semi-active suspension damping system that was first introduced in 2002 on the Cadillac Seville STS. These days it’s fitted to a wide range of cars, from the Lamborghini Huracan to the Audi S3, and the Ferrari F12 to the Vauxhall VXR8 GTS.

Its use is growing in the premium car sector and the system’s manufacturer, BWI Group, says 300,000 cars will be equipped with MagneRide next year.

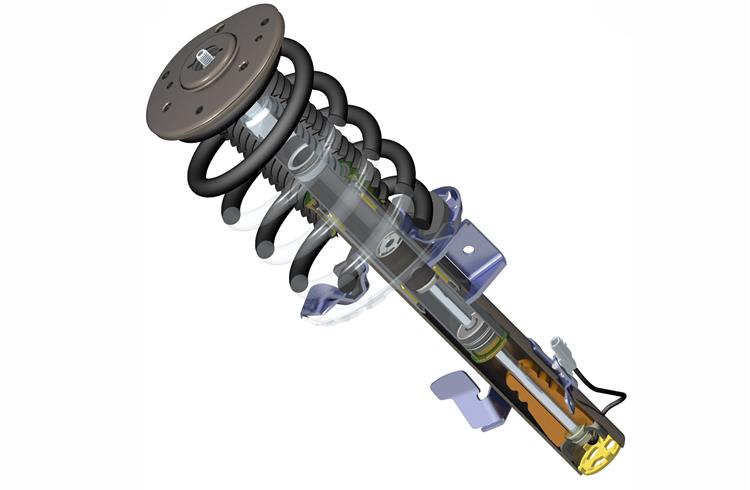

Now in its third generation, MagneRide is fiendishly clever but also simple and reliable, adapting the damping effort in response to signals from a control unit which in turn is given commands from the car’s electronic systems.

In a nutshell, MagneRide technology can alter the damping effort on the fly to suit the conditions and the style of driving. It can make the change in a linear fashion from soft to hard or any stage in between and it can do it in a few thousandths of a second.

Dampers, also known as shock absorbers, literally damp the action of the road springs. Without dampers, the springs would do what springs do best and bounce. Like tennis balls, the wheels would bounce on the road and the body would flounder and wallow on the suspension, making the car unstable. It would roll and pitch, too, reducing grip in corners and making the car unstable under braking, not to mention making life uncomfortable for the driver and passengers.

The basics of a conventional damper are fairly straightforward. A piston fitted with tiny valves moves up and down a tube filled with fluid. The fluid just about squeezes through the valves, but it takes a substantial force to push it through the small passageways in the valves.

How much force is required depends on how much damping effort the suspension engineers want, and that will relate to factors like the strength of the springs and whether the car is designed primarily for performance or comfort.

The design of the valves and viscosity of the fluid determine how much effort it takes to move the dampers. Most dampers are fixed rate but cars with ‘sport’ settings are often equipped with electrically adjustable valves to change them from a harder to a softer setting by increasing the size of the opening that the fluid has to flow through.

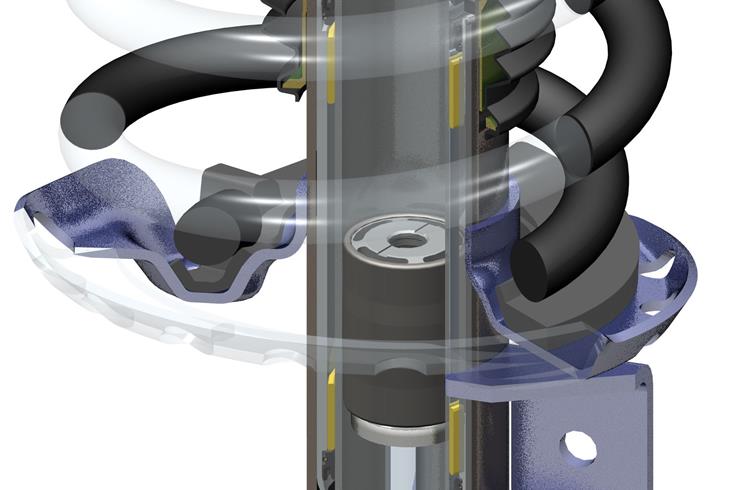

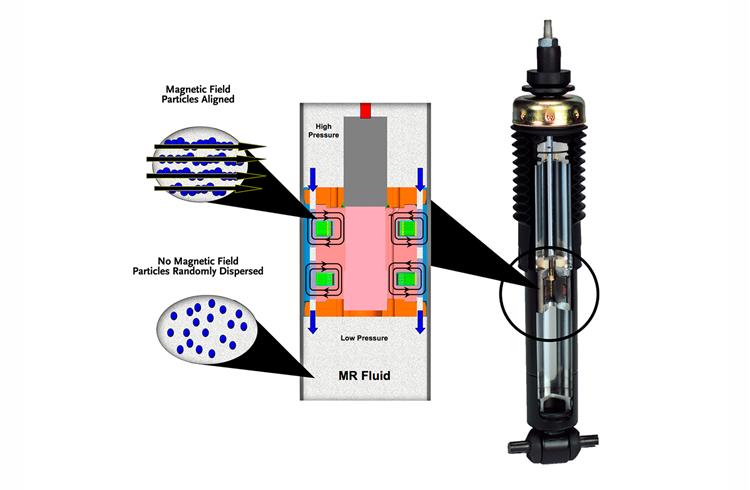

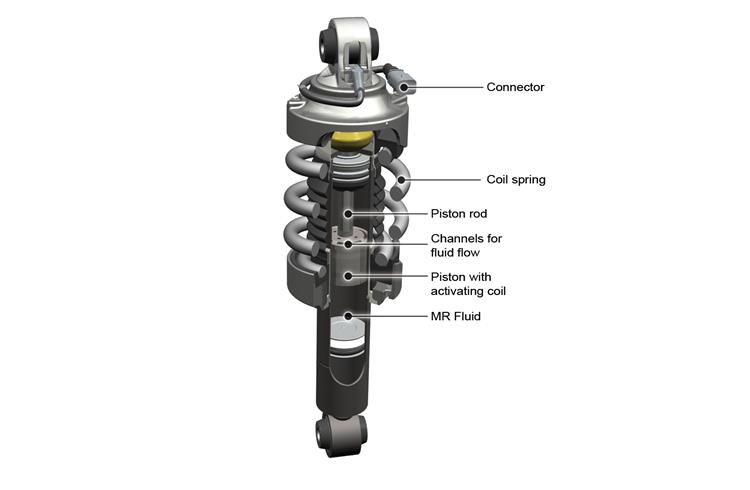

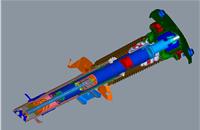

The mechanical design of the MagneRide damper is less complicated. There are no valves, just passages to allow the fluid to pass through the piston as it moves.

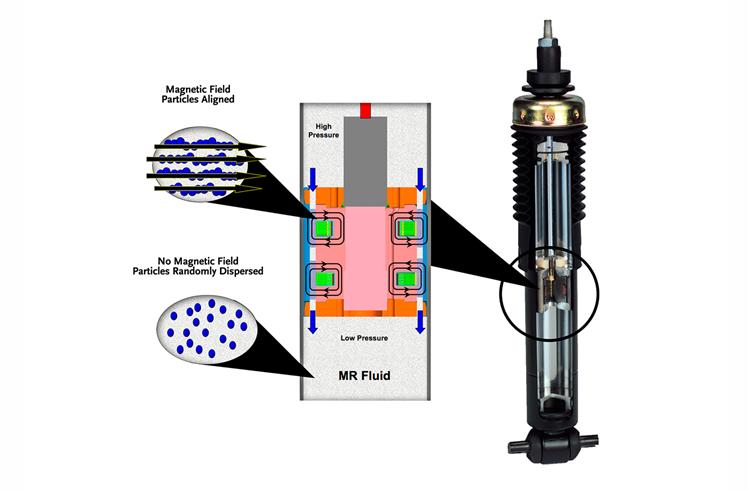

What changes to adjust the damper from soft to hard is the fluid. The secret behind MagneRide lies in a technology called magnetorheological (MR) fluid, a kind of synthetic oil containing tiny particles of iron in suspension.

The latest MagneRide system is equipped with electric coils which, when energised, create an electromagnetic field. When that happens, the iron particles align, effectively increasing the thickness of the fluid by creating rigid structures, making it harder to push the fluid through the channels in the piston when it moves. This increases the damping force.

The stronger the field, the more the particles align and the greater the damping force. When the electrical current is switched off, the magnetic field collapses, the iron particles separate and the MR fluid passes easily through the pistons, reducing the damping force.

Again, the concept sounds simple, but one of the challenges when the fluid was first developed was to come up with a formulation that didn’t allow the iron particles to settle out, especially if the damper was unused for a period of time.

Olivier Raynauld, BWI technical specialist, says: “MagneRide is a system. The dampers themselves are actuators but they are driven by a complex control system.”

Like the car’s powertrain, MagneRide has its ECU, which monitors the car’s dynamic state and driver input, usually through existing sensors used for functions like ESP, pre-crash systems and ABS, as well as sensors which monitor the vertical movement of the dampers.

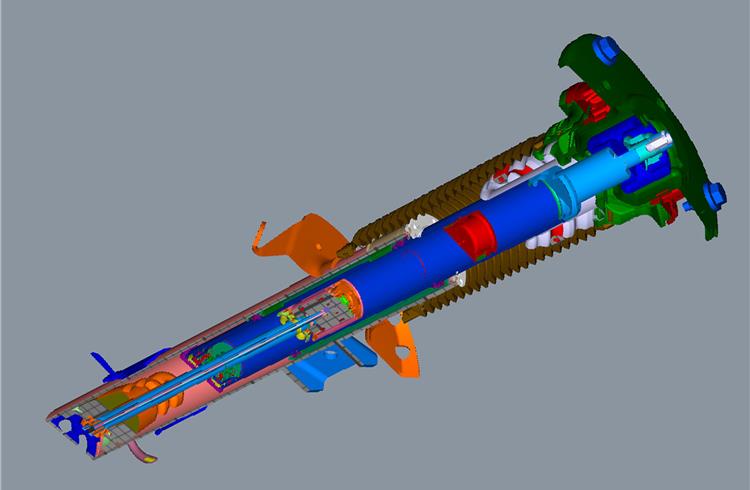

The third-generation MagneRide differs from previous versions by having two coils instead of one for each damper piston. Two coils allow the system to react faster, not when it’s activated, but when it’s de-activated.

When a single electromagnet is turned off, electrical eddy currents cause the magnetic field to linger, only for a few milliseconds, but enough to prolong the damping force longer than is required.

“We’re only talking tiny increments here but it’s enough,” explains Raynauld. By using two coils wound in opposite directions, eddy currents cancel each other out and the magnetic field collapses almost instantaneously, improving the reaction time of the damper from 25 milliseconds to just 13 milliseconds.

As the MagneRide control system has the potential to react to the car’s movements and issue a new command every single millisecond, this improvement made a difference.

“Nobody believed 12 milliseconds was going to be significant until we put it in a car and people were able to experience the difference,” says Raynauld.

As more sensors are added to cars, freely distributing more data relating to the vehicle dynamics via the car’s on-board diagnostics system in real time, so the system continues to evolve.

“Because more data is becoming available, we can make the system respond in smaller and more accurate steps. That will improve comfort, isolation from road imperfections, steering feel and provide more consistency over varying road conditions as time goes on,” says Raynauld.

RELATED ARTICLES

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

Safer toys for India: Behind the scenes at Centy Toys’ factory

Autocar India explores the safety norms that govern the making of scale model cars at Centy Toys.

29 Oct 2014

29 Oct 2014

13741 Views

13741 Views

Autocar Pro News Desk

Autocar Pro News Desk