Delphi targets 2-wheeler canister biz

India's large two-wheeler population has attracted Delphi's attention as the components manufacturer plans to introduce its evaporative emissions systems.

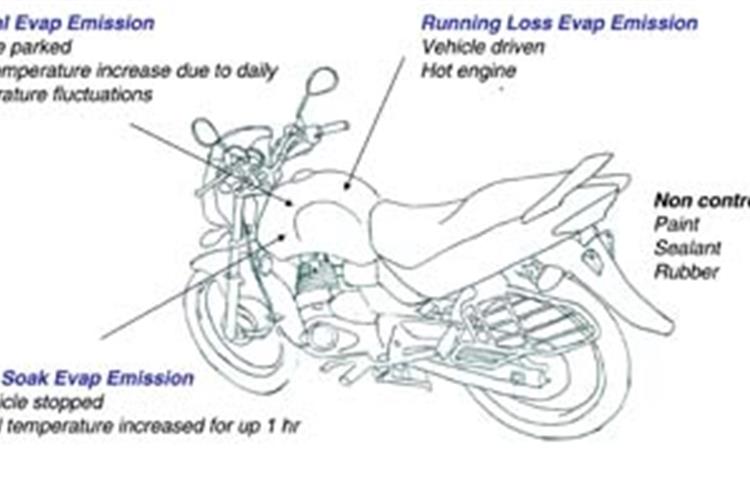

The primary function of the evaporative emissions system is to prevent hydrocarbons from being released into the air and store them in a canister until they can be reintroduced into the intake air stream at a later stage.

“Evaporative emission canister standards have been in place in the US since the mid-1980s. Europe has a different standard wherein they have a canister in the vehicle tank; for refueling, there is a locking device in the gas pump to capture the evaporative emissions from the pump,” says Kevin J Quinlan, vice-president, Fuel Handling Systems, Powertrain Systems, Delphi Automotive Systems China.

Speaking to Autocar Professional, Quinlan notes that Delphi has introduced an evaporative canister for markets like India that can be retrofitted into two-wheelers without direct injection technology. “This canister not only helps in capturing emissions but also increases fuel efficiency. The fuel saved in a year’s time helps you to pay for the canister. ”

Quinlan says that though Delphi supplies evaporative emission canisters to car manufacturers in India, it is targeting two-wheeler OEMs manufacturing carbureted vehicles for the first time. “I have had talks with major OEMs, both two- and four- wheeler manufacturers and the response has been very favourable.

We have Delphi personnel working closely with engineers at many of these OEMs to design the right solutions,” he adds.

Export strategy

Delphi’s strategy is to introduce this new product through an OEM followed by the aftermarket. Quinlan believes there is substantial scope for exports in the long run for evaporative canisters. “We can use India as a manufacturing base for such products for exports. Our predominant strategy to is to know the local market well and establish a relationship with the local supplier base and support them as they begin to export,” he says.

Delphi operates on several fronts to curb emissions. In markets like India it has a two-fold strategy – localisation and sustainable technology.

“Localisation is extremely important because we need to develop the right products for the market. We need to have a very tight relationship with the OEMs to understand what they need to be successful in the market. When working with some Indian OEMs, it is our engineering integrating with their engineering to try and bring the right CO2 emission solutions to the vehicles so that we do not bear tremendous amount of cost. At the same time, we offer them solutions that allow them to meet the emission standards here in India but also achieve export requirements. Another important element that is often not legislated is the evaporative emissions,” he points out.

A growing business

Delphi has been supplying evaporative canisters for four-wheelers since the mid-1990s. “We have not yet introduced the product for two-wheelers in India,” says Prashant Shah, Director, Powertrain, Delphi Automotive Systems. “Typically we introduce the evaporative canisters along with direct injection gasoline systems as emission norms and legislation catch up. What is unique is that our product can be retrofitted in the existing two-wheelers. It will allow OEMs and individual vehicle owners to improve their evaporative emission conditions and fuel economy. The process for installation is also very simple,” claims Quinlan.

He further adds that on the ‘green’ side, Delphi brings technology which it thinks will bring the Indian OEM on a level playing field with the rest of the world. “We can supply them a technology manufactured locally. We are among the few companies in the world that can bring the green, safe and connect technology together for an OEM,” he says.

Explaining the evaporative emissions effects on the atmosphere, Dr Ravi Damodaran, Chief Engineer, Technical Centre India of Delphi’s Powertrain Systems, says that these emissions are hydrocarbons which can create ground level ozone (topospheric) and photochemical smog. “Ground level ozone is an air pollutant with harmful effects to our plants, our respiratory systems, and an irritant to our eyes,” he says.

Damodaran notes that most governments worldwide are working to regulate evaporative emissions to reduce ground level ozone. In India around nine million two-wheelers and 400,000 three-wheelers are sold annually, joining a population of over 100 million two- and three-wheelers on Indian roads. “This technology helps convert over 90 percent evaporative emissions into direct fuel savings by recycling it back into the engine and can be retrofitted to existing bikes,” he adds.

India offers hope

Like most companies, Delphi too has been affected by the global economic meltdown, especially with orders from global OEMs slowing down. But according to Quinlan, since being spun off in 1999 from being a GM division, Delphi is now evenly balanced with a third of its business coming from North America, another equivalent amount from Europe and the remaining from Asia-Pacific. “So when the entire market is going into recession, we need to do some belt tightening. But we feel that there are some markets where we are advised not to do it, for instance India and China. Although we are seeing slow GDP growth, it is strong. We do not want to harm ourselves by stopping our investments and stopping our growth in these markets. We think the economies will rebound hopefully in 2010,” he says.

But just bringing a product and tech from abroad is not enough, says Quinlan. That’s where localisation and the need to work with OEMs come into play. “The second part of localisation is that we adopt the local supplier base. This gives us cost competitiveness and also a kind of interaction we try to provide the OEM with our supplier base,” he says.

Quinlan believes that the current downturn is an opportunity for expansion. “India is one of the places we can continue to invest and expand our portfolio because the GDP in India continues to grow as compared to other countries. Obviously, we do not want to lose on this opportunity,” he adds.

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

By Autocar Pro News Desk

By Autocar Pro News Desk

19 Dec 2008

19 Dec 2008

9080 Views

9080 Views