Dana India innovates for OEMs' efficiency drive

Dana India innovates for OEMs' efficiency drive

The Indian arm of Dana Holding Corporation, the Ohio, USA-based supplier of automotive drivelines, sealing and thermal management components, is currently collaborating with some leading international as well as local Indian OEMs to optimise the weight of their vehicles.

The company plans to localise some axles from its line of innovative Spicer AdvanTEK axles, which are popularly known for providing best-in-class noise, vibration and harshness (NVH) performance and greater power density in a lightweight and compact package.

SaketSapra, managing director, Dana India, told Autocar Professional: “As a global leader in the design and manufacture of technologically advanced products, Dana offers a number of technologies that enhance vehicle efficiency by reducing the weight of components. Dana is in the process of localising the Spicer AdvanTEK axle to meet the demands for a full range of light-vehicle applications, including passenger cars, SUVs, LCVs and utility vans. These lightweight, durable and highly fuel efficient axles enable automakers to include the lightweight aluminium housing, which helps in reducing the overall product weight. These high-performance axles are a prime example of Dana’s efforts to address efficiency, power density, fuel economy, torque-carrying capacity, and weight.”

Working in conjunction with Indian OEMs, the company deploys its CAE expertise to enhance the conventional axle design, which can achieve weight reduction by up to 22 percent.

“In the commercial vehicle market, Dana uses a virtual computer-aided engineering process to enhance axle design that can reduce weight by up to 22 percent. The Spicer two-speed solo and tandem axles are the prime examples of the possible efficiency gains through smart engineering. We expect these innovations, which are currently in the prototype testing phase, to deliver a 12 percent fuel efficiency improvement for our customers (likely to be medium and heavy CV applications),” added Sapra.

STRONG TIES WITH MAHINDRA

In October last year, the company had announced that it would be supplying its efficient and lightweight Spicer axles with AdvanTEK gears to Mahindra & Mahindra (M&M) for the latter’s new platform of SUVs and LCVs.

The proven, lightweight, rugged, banjo-style Spicer model 180 axles are said to be engineered to deliver enhanced efficiency, best NVH performance, and fuel economy through lower hypoid offsets. As planned, the manufacturing operation of these axles is expected to begin in 2015 at the Chakan plant of Spicer India, a JV set up in 1993 between Dana Holding Corp and the Anand Group.

Dana India is known for having designed, developed and supplied the front and rear axles for M&M’s Quanto and also Spicer rear axles (with AdvanTEK gear sets) for the Xylo.

On the engine sealing front, Sapra highlighted that products like Dana’s Victor Reinz thermal-acoustical protective shielding (TAPS) protect the engine from extreme temperatures, while suppressing noise, and lowering overall mass with the use of thinner materials, leading to improved fuel economy.

According to company data, Dana Holding Corp supplies these Victor Reinz sealing products and thermal-acoustical protective shielding (TAPS) to Mercedes-Benz globally for its S400 Hybrid model.

TECH TALK FROM DANA'S PUNE BASE

Earlier this year, the company has set up its technical centre in Pune to boost its local engineering capabilities and hasten the product development and product approval cycle. Having invested nearly Rs 180 crore in setting up this facility, the tech centre enables the company to perform all R&D-specific operations from product design to building product prototypes. Home to over 240 engineers, the unit is fully integrated with Dana’s global research and development system.

Spread across 8,000 square metres, the technical centre houses some crucial facilities such as axle testing labs (dynamometers for light vehicles and HCVs), embedded systems lab (software development for engine control units and others), fatigue area (linear, rotary actuators and other machines), materials lab, multi-axis spin stand and other sophisticated equipment.

Talking to Autocar Professional on the sidelines of the inauguration of the tech centre in Pune on January 28 this year , Robert Pyle, president, light vehicle driveline technologies, Dana Holding Corp, had said that “this technical centre will be dedicated to our Indian operations and other markets, which will include Europe, Thailand, Australia, Indonesia and some parts of USA. While the market is down and is low on sales, it is intentional on our part to inaugurate our new technical centre during these tough times as want to demonstrate that we are bullish about India and firmly believe in the mid- and long-term growth prospects of this region.”

Dana India’s prominent customers include Ashok Leyland, Caterpillar India, Deere & Co., Maruti Suzuki, Force Motors, Ford India, General Motors India, Mahindra & Mahindra (M&M), Mahindra Trucks & Buses, TAFE, Tata Motors, VE Commercial Vehicle and others. The company’s export clients include Ford Motor Company, Land Rover, Nissan, Renault, Toyota and Caterpillar.

SOME DANA LIGHTWEIGHT PRODUCTS

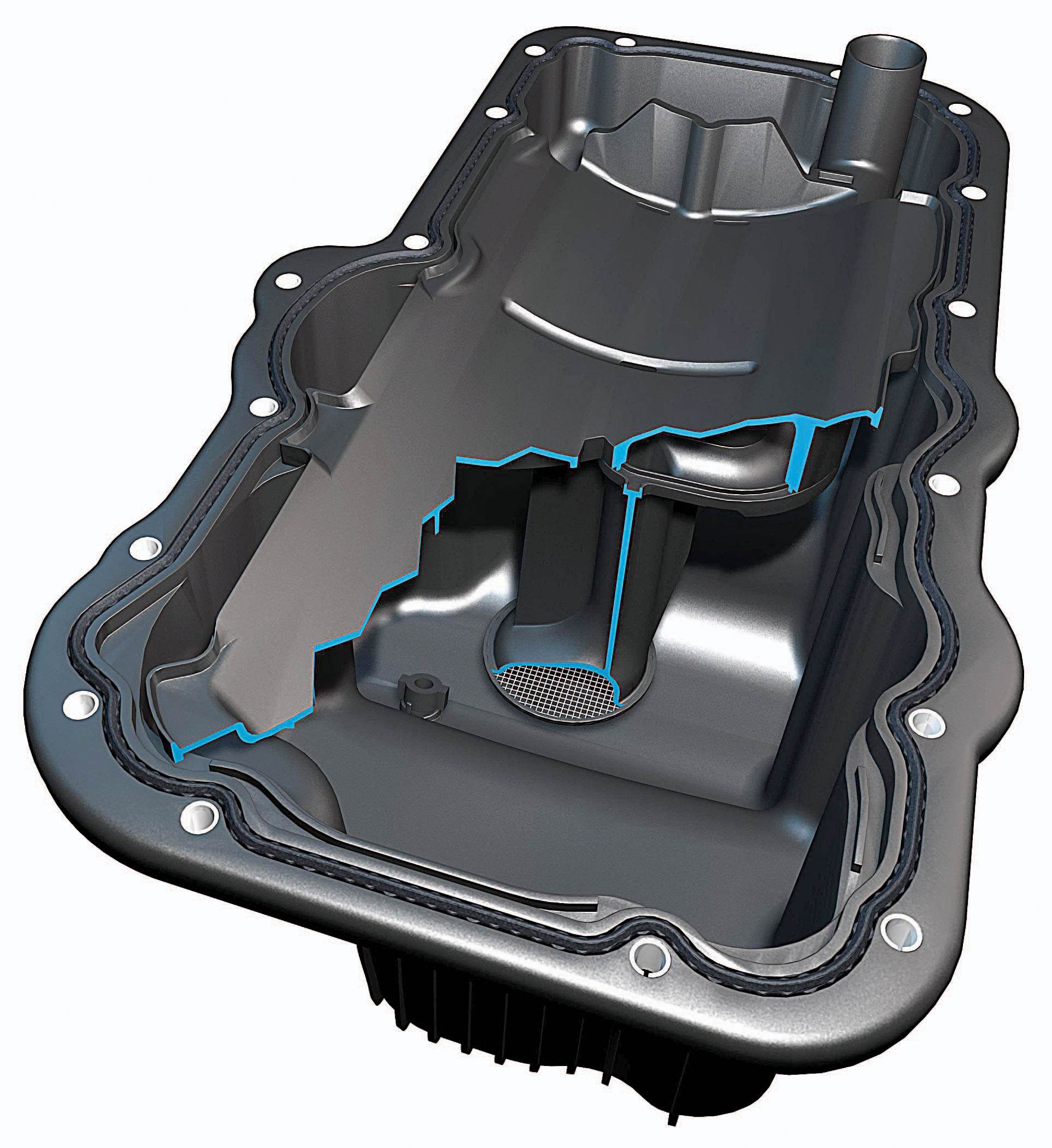

THERMOPLASTIC OIL PAN

Dana has applied the advantages of thermoplastics to oil pans. Its thermoplastic oil pan was designed to withstand the most rugged conditions, including stone impacts and temperature extremes. It also provides superior NVH performance. Additionally, the lightweight resin material, combined with the oil pan’s unique ribbed design, offers significant weight reduction of up to 50 percent — and cost savings of up to 30 percent — when compared with cast aluminium.

THERMOPLASTIC CYLINDER HEAD COVERS

Dana’s thermoplastic cylinder-head cover modules are lighter and deliver significant cost savings when compared to the aluminium cover that it replaces. By utilising plastic, the contributed weight savings to the overall mass of the vehicle improves fuel efficiency and reduces emissions. Plastics enable cover modules to be manufactured simply, cost-effectively, and quickly. Time-consuming machining steps, such as turning, milling, and drilling, are eliminated because moulded plastic cover modules come out of the machine in their final shape and finish.

ALUMINIUM DRIVESHAFTS

As the pioneer of the first-ever aluminium driveshaft, Dana helps to improve vehicle fuel economy through reduced weight, while also delivering better power transfer than traditional steel products.

Dana engineers use the company’s proprietary magnetic-pulse welding to join steel end-fittings to an aluminium shaft for maximum strength at a reduced weight of up to 30 percent. The lighter material makes the driveshaft corrosion-resistant, more efficient, and will help automakers hit aggressive fuel economy targets, while maintaining all the benefits once considered possible only with steel.

INTERVIEW SAKET SAPRA, MANAGING DIRECTOR, DANA INDIA

What technologies does Dana use to reduce weight? Is it using metal alloys, aluminium or polymers instead of metals/steel?

Dana’s lightweight solutions utilise a mixture of materials and innovative engineering processes to help automakers improve fuel economy, while maintaining maximum reliability and durability for the product’s function.

For the drivetrain, Dana’s Spicer aluminium driveshafts help reduce weight by up to 30 percent, and our Spicer AdvanTEK axles can be customised to include aluminium carrier housings and laser-welded ring gears for further weight reduction benefits.

On the sealing side of our business, we offer thermoplastic oil pans and cylinder-head covers that reduce weight by up to 50 percent compared with the aluminium products they replace.

Does Dana work with OEMs from concept and design stage through to delivery of the final product? What role do the inputs from Dana play in the overall vehicle development?

As a technology-focused supplier, we work alongside our OEM customers to find the right solutions for each individual vehicle model. In some cases, this means working to address a specific problem, such as improving how quickly a vehicle warms up. In 2012, Dana received the Automotive News PACE Innovative Partnership Award with Ford Motor Co for its Long brand of active and passive warm-up units, which improve fuel economy by 4 percent.

In other cases, Dana engineers are able to help the OEM choose the right solution for their vehicle based on the variables being measured. For example, efficiency of any powertrain component is not fixed. Each engine, axle, or transmission performs differently under changing variables, such as speed or temperature. Understanding how these variables affect a specific product, like an axle, enables automakers to decide the best combination of products for a vehicle’s design. Dana engineers specialise in understanding how its products perform as efficiency variables are modified, enabling the delivery of the most fuel efficient products to the market.

In which areas has Dana achieved maximum weight reduction? What, in your opinion, are the key areas in a passenger car where weight can be substantially reduced?

Dana has been very successful at finding lightweight product solutions for its customers. The greatest reductions have been achieved using a combination of materials and innovative processes. For example, Dana engineers developed driveshafts using the company’s proprietary magnetic-pulse welding technology that joins a lightweight aluminium shaft to industry-proven steel end-fittings. The assembled driveshaft is up to 30 percent lighter in weight, equally strong as an all-steel driveshaft, and supports automakers’ aggressive fuel economy targets.

In another case, Dana applied the advantages of thermoplastics to oil pans, which are designed to withstand the most rugged conditions, including stone impacts and temperature extremes. The lightweight resin material, combined with the oil pan’s unique ribbed design, offers significant weight reduction of up to 50 percent — and cost savings of up to 30 percent — when compared with cast aluminium, and also provides benefits in noise, vibration, and harshness characteristics.

In the near term, the most significant weight reductions will likely be found in the body and structures of the vehicle, but there still remains opportunity to improve efficiency, increase power density, and reduce weight in the drivetrain.

How do you see Indian OEMs and suppliers adopting to advanced technologies as compared to other emerging economies?

The rate of technology development and adoption is accelerating in every part of the world. The types of technology — such as safety, emissions, or fuel efficiency — are adopted at different speeds and times based on local market requirements and needs. For example, we see the industry in China and Brazil increasing its focus on technology to reduce emissions, while OEMs in India are putting emphasis on our solutions that help lower purchase price and operating costs of vehicles.

The entire global industry is focused on improving safety and performance, though the technology utilised and general approach by OEMs varies widely by region, based on the appetite and readiness of their customers.

What are the global synergies in executing or achieving lightweighting of various products at Dana Corp? Is the Dana Technical Centre in Pune supported by other global facilities on this front?

Dana has a network of nearly 100 engineering, manufacturing, and distribution facilities in 26 countries serving customers around the globe.

We have strategically placed technical centres in each of our key markets to address the specific needs of local OEMs. These technical centres work together to leverage the knowledge from other regions, which helps to advance our entire product portfolio. We also have the unique position of working with light-vehicle, commercial-vehicle and off-highway systems, which enables us to look at solutions that can be scaled across these segments.

How was FY2013-14 for Dana in India and how do you see market growth going forward?

Typically, we don’t disclose the financial year details by country but I can tell you that Dana is confident of future growth in India. Our advantage in India and throughout the Asia-Pacific region is our investment in the development of advanced technologies that would improve the return on investment for end-users. Manufacturers and end-users alike would recognise the long-term value of our products.

Dana has been committed to this market for decades. India is important to our long-term strategic plan, which is focused on sustaining Dana’s position as a global technology leader. We look at the Indian market as having a great potential for growth.

RELATED ARTICLES

BRANDED CONTENT: Eliminating the worries of battery charging with smart solutions

The charging infrastructure is the backbone of electric mobility but is also one of the key perceived barriers to EV ado...

The battery-powered disruptor

Greenfuel Energy Solutions is planning to shake up the EV battery market with the launch of a portfolio of specially eng...

SPR Engenious drives diversification at Shriram Pistons & Rings

The engine component maker is now expanding its business with the manufacturing of motors and controllers through its wh...

07 May 2014

07 May 2014

8028 Views

8028 Views

Autocar Pro News Desk

Autocar Pro News Desk