Continental’s fluidic nozzle cuts water use

Optimum cleaning and the best possible use of resources is achieved by covering the whole swept area with water before the wiper blade moves across it. This prevents the smudges caused by wiping a dry windshield and avoids the need to spray again.

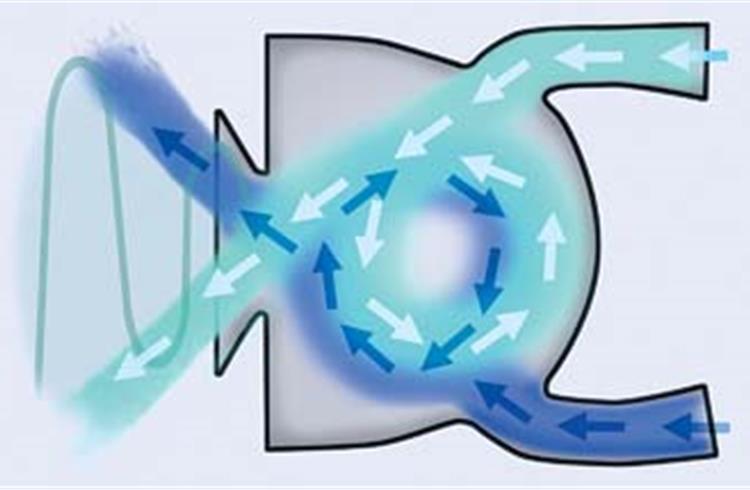

Optimum cleaning and the best possible use of resources is achieved by covering the whole swept area with water before the wiper blade moves across it. This prevents the smudges caused by wiping a dry windshield and avoids the need to spray again. The special design of the Fluidic nozzle keeps the pressure constant and ensures even, rapid coverage using little water due to its oscillating jet. To the driver, the jet appears like a spray fan. The nozzle itself does not move but the oscillating jet is created by the geometry inside the nozzle’s plastic ducts. The geometry is also responsible for adjusting the aperture to the correct vertical and horizontal angles. Vortices, produced naturally by flow dynamics in the nozzle ducts, make for a rapidly oscillating jet which is rapidly, evenly and finely distributed over the windshield or headlamp.

This design has allowed Continental’s engineers to reduce water usage by almost half compared with eyeball nozzles, meaning either that a smaller water reservoir can be installed or that the screenwash water will last for longer. Because water distribution has been optimised, drivers do not need to operate the windshield washer controls for quite so long nor re-fill the reservoir so frequently.

The Fluidic nozzle can also be installed as a ‘Double Spray’ version, in which two oscillating jets per nozzle, one for the upper and one for the lower half of the windshield, provide even better coverage. A Fluidic nozzle can ensure good visibility even at high speeds and especially as windshields become flatter and larger for aerodynamic reasons. Around 60 percent of all European vehicles are already equipped with Continental cleaning nozzles.

Optimum cleaning and the best possible use of resources is achieved by covering the whole swept area with water before the wiper blade moves across it. This prevents the smudges caused by wiping a dry windshield and avoids the need to spray again. The special design of the Fluidic nozzle keeps the pressure constant and ensures even, rapid coverage using little water due to its oscillating jet. To the driver, the jet appears like a spray fan. The nozzle itself does not move but the oscillating jet is created by the geometry inside the nozzle’s plastic ducts. The geometry is also responsible for adjusting the aperture to the correct vertical and horizontal angles. Vortices, produced naturally by flow dynamics in the nozzle ducts, make for a rapidly oscillating jet which is rapidly, evenly and finely distributed over the windshield or headlamp.

This design has allowed Continental’s engineers to reduce water usage by almost half compared with eyeball nozzles, meaning either that a smaller water reservoir can be installed or that the screenwash water will last for longer. Because water distribution has been optimised, drivers do not need to operate the windshield washer controls for quite so long nor re-fill the reservoir so frequently.

The Fluidic nozzle can also be installed as a ‘Double Spray’ version, in which two oscillating jets per nozzle, one for the upper and one for the lower half of the windshield, provide even better coverage. A Fluidic nozzle can ensure good visibility even at high speeds and especially as windshields become flatter and larger for aerodynamic reasons. Around 60 percent of all European vehicles are already equipped with Continental cleaning nozzles.

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Autocar Pro News Desk

By Autocar Pro News Desk

04 Mar 2009

04 Mar 2009

6551 Views

6551 Views