Brembo celebrates 40 years in Formula 1

The Brake By Wire (BBW) system, optimised braking system cooling, innovative brake calipers and advanced in disc technology

The Brake By Wire (BBW) system, optimised braking system cooling, innovative brake calipers and advanced in disc technology are just some of the most significant new developments to be introduced for the 2015 season.

With an involvement in Formula One beginning in 1975, Brembo – the world's leading producer of advanced braking technology and high performance braking systems – celebrates its 40th anniversary in the world's premier motorsports series and reasserts its technological leadership by equipping the most important teams with its braking systems for the 2015 season, for example: Infiniti Red Bull Racing and Scuderia Ferrari.

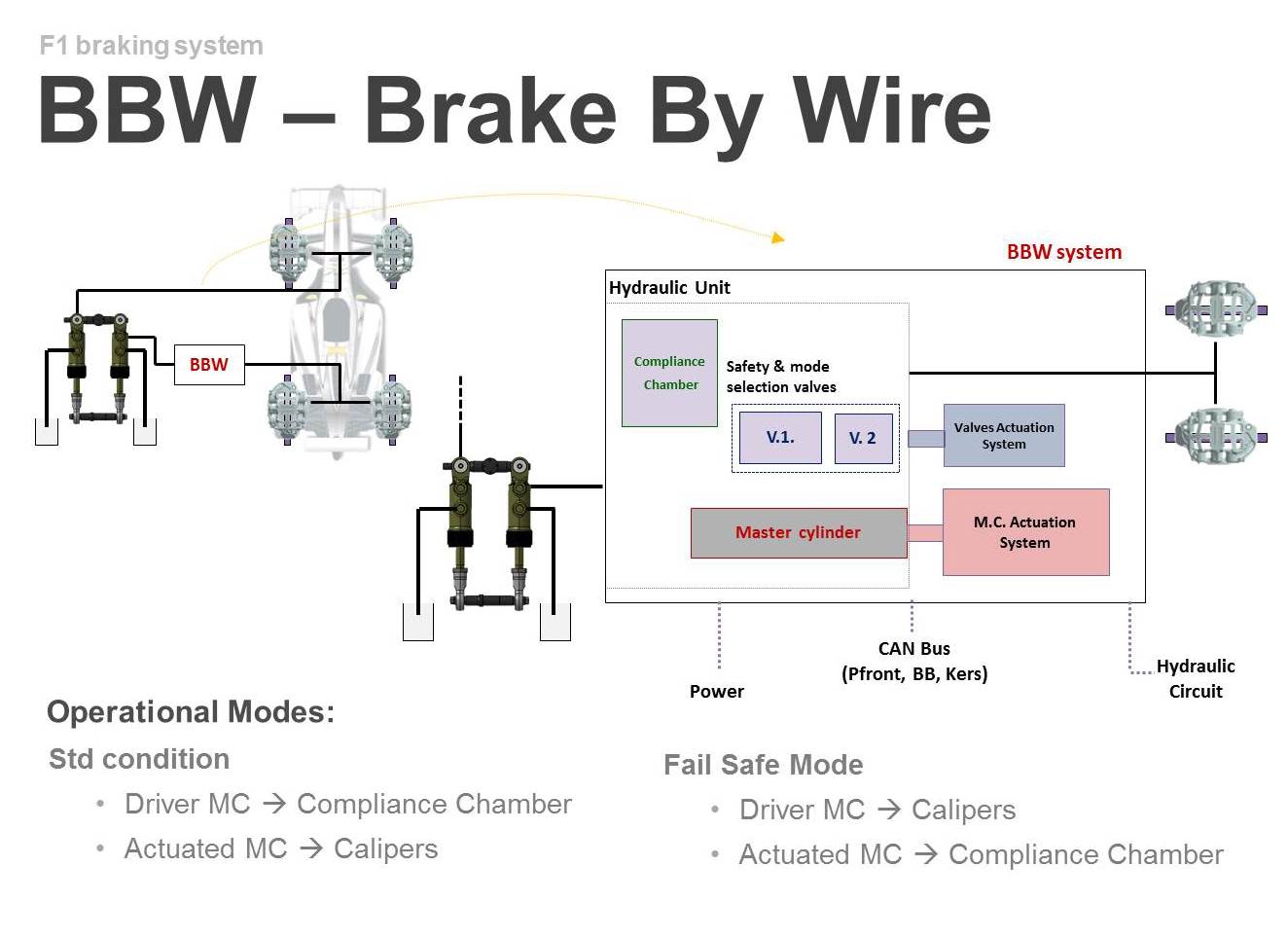

Following the significant changes in regulations introduced in 2014, which revolutionised braking systems with the introduction of Brake By Wire (BBW) technology, the 2015 season ushers in yet another evolution in assisted braking, alongside major improvements to further optimise brake system cooling.

The teams equipped by Brembo will be using new more efficient brake calipers which benefit from a better integration into the wheel corner – a factor which also contributes to improving the overall aerodynamic performance of the race car. The manufacture of each of these new brake calipers in aluminium/lithium requires over 14 hours of consecutive machining to achieve the perfect balance between weight and stiffness.

How Brake By Wire works

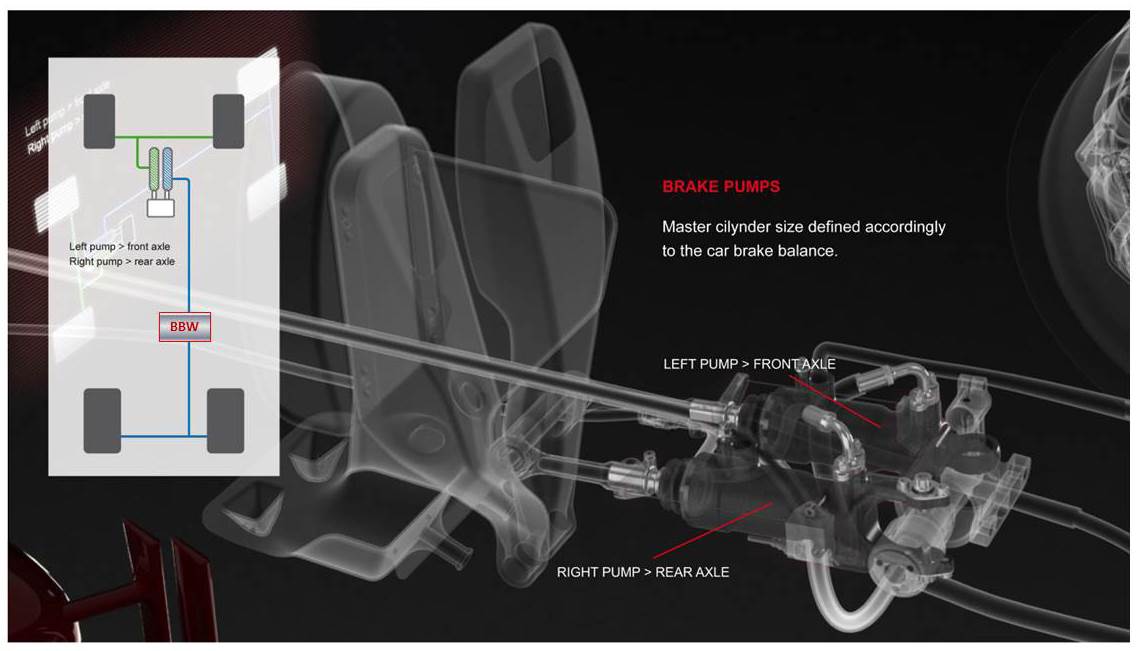

Brembo says it was responsible for the design, simulation and engineering of the brake system as a whole and of the individual components of the Brake By Wire system. With the benefit of 40 years of experience in racing and the Italian company's continuous commitment to investing in research and development, the company’s engineers further broadened their skills in order to develop and produce a variety of different BBW components in response to the requisites of each individual team. In addition to this, the engineers also worked to optimise the assembly of the parts within the system and to further miniaturise the components themselves.

For certain teams, Brembo developed the actuator only, which acts as an interface between the hydraulic system of the race car and the rear calipers. For other teams, Brembo conducted more extensive projects encompassing a substantial portion of the BBW circuit, such as the valves switching the Brake By Wire system between normal and emergency operating state and the simulator recreating the sense of stiffness in the rear circuit to provide the driver with adequate brake pedal feedback.

In 2014, the brake balance was shifted even more towards the front wheels, while as the year progressed, maximum braking torque increased by 15 percent. This increase in braking torque was the result of continuous developments in aerodynamics, which increased the amount of available grip. Even more effective brake disc ventilation In recent years, Brembo's engineers have continuously improved brake disc cooling – as in Formula 1, the discs can reach temperatures of up to 1200degC – by increasing the number of ventilation holes (with up to 1200 holes in some cases) and optimising the fastener system between the disc and the hat to increase structural strength.

Increasing the number of holes in the disc can only improve cooling performance if the mass flow through the holes is sufficient to ensure an efficient heat exchange, and this was ensured through advanced CFD (Computational Fluid Dynamics) analyses and a synergistic optimization process with each individual team in the design of their specific brake duct for their specific car. The discs now have more numerous, smaller ventilation holes, exponentially increasing the area of the carbon surface in contact with the air flow and, as a consequence, the ability of the disc to dissipate heat. The structural evolution not only called for a much more complex and delicate machining process, but also for a more extensive understanding of fluid dynamics theory. The contribution of the engineers of each individual team was crucial in optimising the air intakes of the new race cars for these discs.

Less brake system wear with CER

Even the material from which the discs are made has changed radically. The CER carbon brake disc material significantly reduces wear while ensuring more effective heat conduction, reducing the warm up time needed to reach operating temperature, and offering a broader operating range in terms of both pressure and temperature, together with very linear friction characteristics.

All of these attributes contribute to giving the driver extremely precise control over the braking system. Furthermore, the incredibly low wear rate of this material ensures consistent, repeatable performance from the start of the race to the chequered flag.

For the 2015 season, all teams equipped by Brembo will use the same CER 300 disc material, while Brembo continues its research in this field to produce composite materials that continue to offer more performance and controllability. All teams are equipped with new ventilated CCR 700 brake pads.

Key facts and figures

In a complete season, on average Brembo supplies the following materials to each team running 2 race cars: 10 sets of calipers, between 140 to 240 discs, and 280 to 480 brake pads.

Opening Brembo stall images copyright LAT Photographic

RELATED ARTICLES

Branded content: HL Klemove inaugurates first Local ADAS Radar Manufacturing Unit in India, marks a significant achievement in “Make in India” initiative

The inauguration ceremony was held in the presence of Vinod Sahay, President and CPO of Mahindra & Mahindra Ltd. and Dr....

BluWheelz to 'Green Up' logistics sector

With their EVs-as-a-service solution, the startup is playing it smart with costs and looking to electrify the entire seg...

BRANDED CONTENT: Spearheading the EV revolution in India

Jio-bp is a joint venture between Reliance Industries and BP PLC where both entities have married international expertis...

By Autocar Pro News Desk

By Autocar Pro News Desk

18 Mar 2015

18 Mar 2015

12992 Views

12992 Views