2012 Lightweighting Special: Lanxess:India has huge growth potential

Lanxess India openeda new plant at Jhagadia in Gujarat in January this year as part of its commitment to India.

|

What is Lanxess’s specialised focus area in the field of plastics?

Our expertise lies in products made of the highly versatile polymer materials Durethan and Pocan that can withstand substantial mechanical stresses and impress with their excellent reliability in continuous use. These properties, combined with easy processing, media resistance, good insulation and high impact strength, make them very popular high-tech materials – especially with the automotive industry and its suppliers, in the electrical and electronics industry, with manufacturers of household appliances, in the construction and medical industries and, last but not the least, in sports and leisure applications.

In your opinion, what is the market opportunity for engineering plastics in India?

High-tech plastics have a great future. Many companies in the automotive industry in particular, but also in the electrical and construction industries, are making increasing use of these innovative materials.

These lightweight materials offer greater flexibility and open up a whole host of new design options. Growth in the use of high-tech plastics is particularly marked in cars. India is now a global marketplace for cars. International carmakers sell in India and are increasingly expanding in overseas markets. Global regulations, imperatives on reducing carbon dioxide emissions and the need for better features for users worldwide, are driving automotive technology. One of the primary benefits of high-tech plastics is that they make cars lighter by replacing metal parts that are many times heavier. Less weight means lower fuel consumption and thus lower carbon dioxide emissions. This not only shaves off costs but also helps protect the environment. High-tech plastics also play a key role in one of the automotive industry’s most important areas of activity for the future – the development of cutting-edge electric vehicles.

What are the current dominant trends in the automotive plastics market in India?

Indian automobile companies have now begun to look at ways of achieving higher fuel efficiency in cars – using lightweight plastics in particular. Many of them have already introduced cars built with metal composite technology or are planning to do so. With the recently implemented labeling norm for cars, it will be imperative for car makers to adopt technologies that yield better fuel economy.

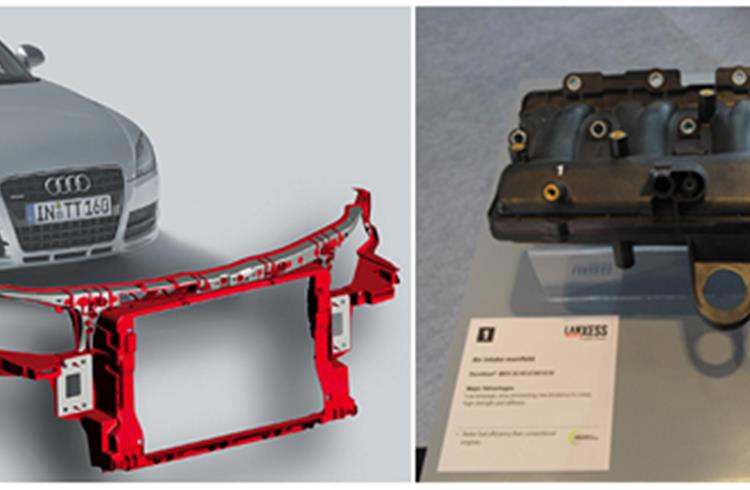

The plastic-metal hybrid technology innovated by Lanxess is used for making front end modules for various cars across the world. OEMs like Tata Motors, Volkswagen, Hyundai and Ford use the Durethan product range from Lanxess for their cars. Audi is using Lanxess technology in its new flagship A8 model. The plastic-metal composite technology is used in the front end of Audi’s new top-of-the-range model. The component is a beam in the engine compartment to which, for example, radiator and headlight assemblies are attached. In India, Ford and Hyundai have used Lanxess technology for their cars. Car models like the Figo from Ford, Getz from Hyundai (now not sold) are produced in India with Durethan-based hybrid front-end modules. Lanxess is optimistic about the increase in use of high-tech plastics by the automobile sector in India. In terms of potential, India is slated to become the third-largest consumer market for plastics after the US and China and the domestic automotive industry would play an important role in this feat.

To what extent can plastic parts replace metal parts to help reduce overall vehicle weight? What has Lanxess’ experience been in this aspect?

We have seen OEMs experience a cost reduction of around 20 percent and weight reduction of around 40 percent by using this technology. More importantly, high dimensional accuracy of the parts due to usage of plastics helps in integration of other parts (modular concept) in the front end with radiator, air cooler, headlamps, grille and horn at the Tier 1 supplier’s end, who further ships this module to the car OEM. This will open up new applications of plastics in automotive engineering for Indian cars. Options like replacement of the structural components of automobiles with plastics or metal-plastic hybrid components are now a possibility which were hitherto only steel or metal-based. Apart from front end modules, we have projects in the pipeline and at planning stages for converting several metal parts into plastics in India such as – air intake manifolds, oil module, door handles, oil pans, coolant water pipes, fuel tank, thermostat housing and fuel rail. These parts have already been successfully replaced with Durethan or Pocan in Europe, Japan and US.

RELATED ARTICLES

Renault-Nissan Alliance rebooted

The Franco-Japanese alliance is all set to unveil an ambitious SUV line-up amidst fresh investments of Rs 5,300 crore in...

BRANDED CONTENT: Eliminating the worries of battery charging with smart solutions

The charging infrastructure is the backbone of electric mobility but is also one of the key perceived barriers to EV ado...

The battery-powered disruptor

Greenfuel Energy Solutions is planning to shake up the EV battery market with the launch of a portfolio of specially eng...

By Autocar Pro News Desk

By Autocar Pro News Desk

31 May 2012

31 May 2012

3098 Views

3098 Views