SGS sharpens India focus, eyes new business from safety and emission tests

Bullish on the Indian market, global inspection, verification, testing and certification company SGS beefs up capabilities in its Manesar laboratory.

SGS India, the local arm of one of the world’s leading inspection, verification, testing and certification companies, looks at operational expansion in terms of new service portfolios, capital investments, machine and infrastructure, capabilities, human resources and other areas aligning itself to the emerging opportunities in the Indian automotive industry in lieu of the new legislation norms.

The Geneva-based company, a global conglomerate with 85,000 employees and a 2015 turnover of CHS 5.7 billion (Rs 36,223 crore), caters to several sectors including automotive. Automotive, along with aerospace and aviation, marine and railways, is clubbed under its transportation business.

The company sees automotive as one sector of increasing importance as several countries worldwide are working towards curbing vehicular emissions and investing in electrification and solar energy. India also falls within the ambit of its high-growth markets globally, thanks to its increasing role in global exports, new upcoming legislations and its promising growth potential.

In a recent interaction with Autocar Professional, Matthias Popp, vice-president, testing service, SGS, revealed that “within our global network, India is among the top five countries in terms of revenue generation through services. It also has the second highest growth rate after China for SGS globally, and from that point of view, this is a very important country for SGS’ worldwide business. We are looking forward to continuous growth here. We plan to expand our services to other geographies within India and across other service portfolios.”

SGS in India is a leading provider of testing and certification services to Tier 1 and 2 component suppliers in the automotive value chain. This is because the company started off its transportation business in India in 2004 by setting up its automotive component testing laboratory in Gurgaon to cater to the local market.

Giving clarity on SGS’ journey in Indian automotive industry, Popp, who is based in Germany, elaborated: “We started in India with interior testing for passenger vehicles at the component level. We think we are the market leader when it comes to compliance at the component level in India. From Gurgaon, we later expanded operations to Pune. On the homologation side, the volume in India is not that attractive as of now from a business perspective. In India, we don’t do homologation as of now. However, we are moving from components to full vehicle testing over time. SGS’ global strengths in automotive services range across the entire spectrum starting from raw materials to the final passenger car.”

According to Popp, conventional foreign testing and certification agencies, also potential rivals to SGS in India, have set up shop with a top-down approach, providing services starting from full vehicle level and moving to components. Notably, SGS’ pathway into the Indian automotive industry has been the reverse of that. The company has been present in India for close to 66 years now, providing inspection services to other sectors, say company officials.

“Over the last 12 years (since SGS India commenced operations in automotive), the company has built up two focused labs, one each at Manesar (Haryana) and Chakan (Pune). We have more than 100 qualified engineers working at the Manesar laboratory. This is one part of the business. Besides this, we have been helping the Indian automotive value chain with our services such as training, consultancy, certification of systems and processes among others. We help the local value chain compete with the global supply chain of their bigger counterparts. Services under functional safety are yet another domain we cater to,” added Dipjyoti Banerjee, business director, transportation, SGS India.

Operational expansion

The company moved into a larger facility in Manesar in May-June last year under its drive to expand current service portfolios for the industry. According to Banerjee, although the company has been using technical equipment and the latest machines in line with the best practices, the new Manesar facility offers the scope of new functional roles through new layout, optimised productivity and space for future expansion. “Operations at our Manesar laboratories are mostly for the Indian automotive value chain,” commented Banerjee.

The senior company official, however, declined to disclose the investments made on the new, upgraded Manesar facility.

That said, SGS is also eyeing the scope of keeping close connect with most of its clients in India. “We are aware of the many automotive belts in India including the upcoming automotive districts in Gujarat. We are also considering these belts where our customers are going to as proximity to clients is very important,” clarified Popp.

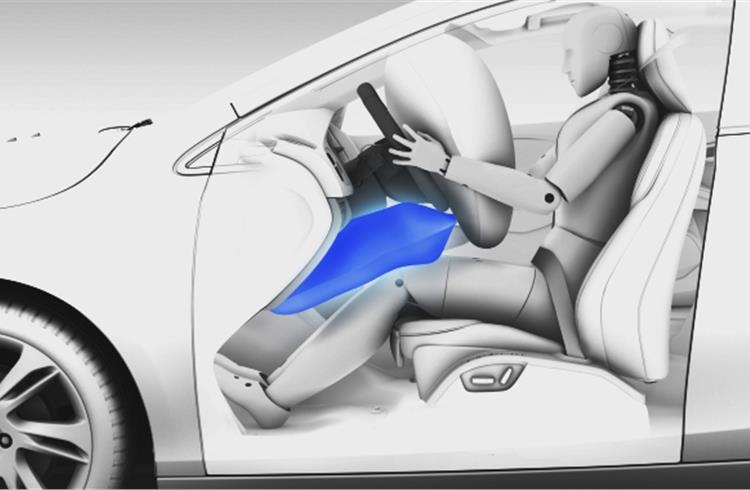

The company officials welcome the upcoming safety (ABS and airbag technologies) and emission regulations (BS VI norms) for the industry. While they are positive about the Indian auto industry upgrading to global benchmarks, they also see this transformation in the form of several opportunities to penetrate deeper by climbing higher in the value chain.

“We have been waiting for some of these legislations in India for some time. There will be new services that will be sourced from us especially in the emission-related areas,” said Popp.

SGS is known to have made a few acquisitions in the USA over the past five to six years, which have helped it develop new capabilities on the testing front and evaluating real-time driving emission testing. One such acquisition it made was in May 2015 when it bought Michigan-based Testing Services Group (TSG), a leading provider of fuel systems testing for global customers in the automotive, small engine, marine, and US government markets.

“Also, aging services for catalytic converters because they age over time and we want to make sure that from a filteration point of view, they should remain effective. Our acquisitions in the USA brought certification abilities in the domain of functional safety including ABS, ESP, lane departure, lane assist and also autonomous features along with relevant ISO standards,” said Popp.

Material testing laboratory at SGS India's Manesar facility, which mostly caters to automotive requirements. More than 100 qualified engineers work at this state-of-the-art facility.

Many powertrain manufacturers (for the India market) and their associated key suppliers are estimated to work overtime, accommodating development, testing and validation cycles to meet the stiff deadlines for BS VI emission norms by April 2020.

According to the senior company official, most of the core engine development for India still takes place either in Japan or USA or Europe. “We see a lot of activities happening in the R&D centres of the engine makers back in Europe,” he remarked.

However, Popp strongly believes that after the BS VI emission norms come into effect in India, which is a highly cost-sensitive market, buyers will switch from small diesels to petrol cars. “Most likely, we will not see much of diesel in the market because smaller cars conforming to BS VI diesel engines (1.2L, 1.3L, 1.4L) would become too expensive to be sold. However, if the legislations are relaxed a bit on the NOx front, then diesel engine technology could be made more affordable. This is a good move by the government. In my opinion, this should be complemented with electrification of two-wheelers,” he observed.

Betting big on Electric Vehicles

The emergence of electric vehicles marks another paradigm shift beyond tightening of emission norms worldwide. While OEMs and their suppliers are working to build capacities on this front, software simulation providers, as well as the performance testing and validation bodies, are also working on several new evolving benchmarks.

According to Popp, SGS has spent in excess of 10 million euros in building a new battery testing facility in Munich, Germany. The inspection body is working with several key German carmakers helping them with advanced battery technology testing and benchmarks for their respective EV product plans.

Battery costs remain prohibitive in the Indian context. Bullish about the electrification of two-wheelers in India and its potential to take up the manufacturing of electrical components, Popp stated, “Opportunities for India are better than most of the Asian countries. China has a population of more than 40 million electric bicycles. China eradicated conventional fuel-run scooters from all the cities and replaced them with electric ones. This can greatly enhance your air quality, much more, in my personal point of view, than BS VI norms. If you can take out the battery from a two-wheeler and charge it every evening, then it can be easily done.”

“There are a lot of software companies in India. However, from my visits, I understand that a lot of hardware is imported. Most of the suppliers including the major Tier 1s we speak to here are sourcing their hardware from either China or Taiwan. Even the PC ports are made there, which are imported and stuffed in the systems here. That is a big opportunity for the government. If the government ensures a stable infrastructure for the manufacturing of electronic components such as water supply, uninterrupted power supply, clean air and others, then it will get much more depth in production,” he concluded.

This article was first published in Autocar Professional's September 1, 2016, NCR Special.

Click here to subscribe to our print version

RELATED ARTICLES

BRANDED CONTENT: Eliminating the worries of battery charging with smart solutions

The charging infrastructure is the backbone of electric mobility but is also one of the key perceived barriers to EV ado...

The battery-powered disruptor

Greenfuel Energy Solutions is planning to shake up the EV battery market with the launch of a portfolio of specially eng...

SPR Engenious drives diversification at Shriram Pistons & Rings

The engine component maker is now expanding its business with the manufacturing of motors and controllers through its wh...

By Amit Panday

By Amit Panday

15 Sep 2016

15 Sep 2016

11801 Views

11801 Views