Rane (Madras) gears up for next phase of growth

The Chennai-based manufacturer of steering, linkage and die-cast products is consolidating domestic business, aggressively driving exports and innovating to achieve speedier growth.

Rane (Madras) Ltd (RML), part of the Chennai-based Rane Group, the well-diversified global manufacturer of steering and suspension linkages, steering gear and aluminium die-cast products, has returned to the growth track after a sluggish two years.

According to the company’s annual report for FY2015-16, it posted annual sales of over Rs 800 crore, registering growth of nearly 10 percent. It expects to maintain this double-digit growth on back of an uptick in the commercial vehicle sector, growing volumes in passenger cars, utility vehicles and also the recovery in the tractor market in India. It also helps that overall market sentiment is up, the monsoon is well underway and the country’s GDP growth is also sound.

RML, which is one of the Rane Group’s first businesses which was set up back in 1960, caters to manufacturers of passenger vehicles, LVSs, M&HCVs and tractors. While the steering and linkages division manufactures manual steering gear, hydrostatic steering systems and steering and suspension linkage products, the die-casting division produces machined steering housings and machined engine components.

“Last fiscal year was a reasonable one for us. Going forward, we expect a minimum growth of 10-15 percent even as big export business chips in from 2018-19 onwards”, says S Parthasarathy, chief executive officer, RML.

The commercial vehicle and tractor markets have been RML’s core business for decades. This, however, changed 4-5 years ago as leading customer Maruti Suzuki saw rapid sales. The humungous demand for electronic power steering in Maruti cars has seen RML’s steering gear business grow by 20-25 percent year on year. In the domestic market, the company has two other large customers in Mahindra & Mahindra and Tata Motors.

Betting big on the Tractor business

RML has a strong presence in the tractor market in the form of supplies of steering gear and linkages to top tractor OEMs like TAFE, Escorts, Mahindra and International Tractor. The company has developed a new product called hydrostatic power steering for the tractor industry.

Speaking on the new product, Parthasarathy says, “Power steering penetration in the tractor industry is growing rapidly and being a major player in the tractor market, it is a significant focus area for us. We have built a new world-class plant in Mysore and excellent R&D facilities for hydraulics to compete with global brands and gain market share in this segment.”

The new product offers a good opportunity in the domestic market where mechanical steering still finds usage in nearly 65 percent of tractors; RML has over 80 percent market share here. However, the power steering market is largely catered to by overseas players where RML now sees an opportunity. “We expect power steering application in tractors to grow to 50 percent in five years and we want to be a strong player. At present, we are already supplying to TAFE and Kubota and are validated with other customers. In the next 6-18 months, the majority of the tractor makers will be our customers for this product, which will help us touch a market share of 25-30 percent,” says a confident Parthasarathy.

Focusing on hydraulic products for tractors, another recent development was a transport lock valve for a client. This product helps enhance tractor performance and RML is likely to supply it to other customers too. Similarly, tractors have a lot of hydraulics, which are catered to by low-end suppliers. OEMs are now increasingly looking for quality suppliers with engineered products in hydraulics. Thanks to its strong design and testing team, RML foresees sees huge scope in this area. “We can bring significant value to tractor customers in terms of engineered solutions, highly reliable products and good service support as we understand the steering application and tractor business quite well,” affirms Parthasarathy.

On July 25, RML announced its standalone results for the quarter ended June 30, 2016. Sales and operating income for April-June 2016 was Rs 227.56 crore compared to Rs 202.57 crore in April-June 2015. The steering and linkage division’s sales saw an increase of 7 percent thanks to growth across segments in India OEM business and international business. The die-casting division grew 41 percent supported by a strong order flow from global clientele and commencement of new supplies for Indian customers.

Exports get bigger and better

Exports looks very promising for RML, particularly from 2018-19 as the company has secured significant orders from its European and US customers. This is an area where the company has taken giant strides. About a decade ago, export numbers were not much but today they account for 20 percent of its total sales.

The fact of the matter is that the export business is very robust right now and is likely to enhance its contribution to 35-40 percent of total business in the next 4-5 years. “In the last 10 years, we have substantially built our brand overseas and 80 percent of export is to North America for supply of steering gear for niche applications like all-terrain vehicles, golf carts and die-casting products for steering housing in high-volume passenger vehicles,” says Parthasarathy.

RML is now charting out plans to further capitalise exports, supported by its strong manufacturing and engineering capability. It has won a large business order in Europe to supply 400,000 steering gears per annum, starting from 2018-19. In addition, two more programs are likely to come its way and discussions for these are at an advanced stage. These new orders are expected to involve 350,000-400,000 unit volumes within Europe and 200,000 from other geographies. As a result, overall export numbers are set to touch a million units of steering gears for the global market in the next five years.

Besides ball joints, steering gears and die-casting products, the company is also focusing on steering linkages. RML has bagged business in Europe with global OEMs like Daimler and Volvo. With new orders in place by 2022, Europe will account for 40 percent of total exports. However, growth in the US market will continue to be in ball joints while steering gears and die-casting business will grow largely in the European market.

Commenting on supplies to overseas clients, Parthasarathy says, “There are two ways in which we serve customers. Firstly, we have warehouses close to their plants and deliver ‘Just in time’ two or three times a day. There are other customers who source several parts from India, consolidate the procurement and move the parts to their country.”

The company’s quality systems ensure a hassle-free supply chain considering the longer supply time for exports. It’s also an operation that calls for highly reliable manufacturing processes. Interestingly, RML intends to go global on the back of the rising popularity of electric power steering demand for passenger cars. This is backed by its engineering capabilities and world-class manufacturing. The company has positioned itself as an independent supplier to all Tier 1 suppliers of EPS globally.

Strong R&D

Traditionally, RML has been strong in the design and development of ball joints, whose capability has been built over 40-50 years, while steering gear for electric power steering capability has been enhanced in the past five years.

With its unstinting focus on R&D, the company has developed critical products over the years. Add to that a good understanding of customer needs and working on engineering solutions. Sharing an example of an India-specific product development, Parthasarathy says, “The most critical thing in an electric power steering system is ‘rattle’, particularly on rough roads. This problem is not experienced in western markets or in Japan where the roads are good. We identified the improvement in design which is required in collaboration with OEMs and end-customers and spent considerable effort to understand the unique challenges in steering systems on Indian roads. Based on our in-house R&D, we have identified various potential sources of ‘rattle’ and developed specific counter measures to overcome the problem.”

The 50-member strong R&D team, located in Chennai and Pondicherry, is committed to new product development. In 2014, the company set up a world-class R&D facility in Pondicherry for passenger car application equipped with comprehensive test capabilities and a test track to simulate road conditions.

“Our success in the global market is not just because of cost but by our engineering capabilities. One of the major global orders has come to us largely due to the fact that our engineering team was able to generate several ideas to bring down the cost,” says Parthasarathy.

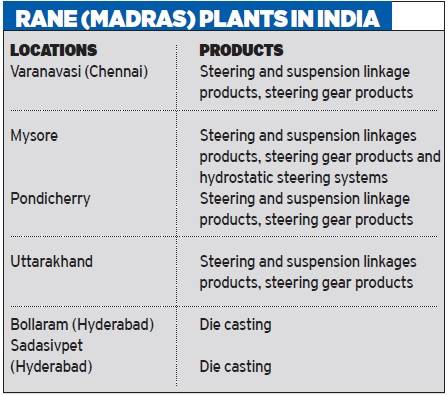

RML has six manufacturing plants in India catering to its domestic and overseas clientele. While the company will continue to invest in existing plants, there is no immediate plan to set up a new facility. RML has allocated spend of Rs 200 crore in the next 3-5 years to expand capacities in its existing plants.

The domestic aftermarket, which is growing by 10-12 percent annually, is also one of its focus areas thanks to it being a consistently profitable business with immense growth potential. At present, the aftermarket accounts for nearly 18 percent of the total business with both an independent network of wide distribution channels and OEMs. The company enjoys strong brand recall in the aftermarket and higher acceptance in terms of quality and product performance.

The aftermarket is essentially direct marketing which needs a lot of fieldwork; RML has a strong 30-member sales team dedicated to this vertical. This team engages with customers through multiple campaigns, creates demand and spreads awareness of using the original brand. “There are a lot of unorganised sector manufacturers who lack quality and reliability and just sell on price. As a responsible manufacturer, it is important for us to educate the users on safety critical parts like ours, and get customers to understand the value in buying our products,” signs off Parthasarathy.

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

By Kiran Bajad

By Kiran Bajad

20 Aug 2016

20 Aug 2016

33497 Views

33497 Views