Nexteer Automotive India to foray into EPS systems

Supplier of driveline components to OEMs in India now aims to tap the burgeoning demand for electronic power steering systems — its core strength worldwide.

Nexteer Automotive, a US$ 3.4 billion company and a leading Tier 1 supplier of advanced steering and driveline technologies to all major automakers globally, is eyeing the growing demand for electronic power steering (EPS) systems in India.

The company, which currently is a large-scale supplier of half-shafts to Maruti Suzuki India and Renault-Nissan in India, plans to design, develop, manufacture and supply EPS systems to OEMs in India. EPS systems are set to see exponential growth in demand on the back of the increasing role of electronics in vehicles and also the tightening emission norms in India.

Notably, although Maruti Suzuki and Hyundai Motor India offer EPS systems in their passenger car models, the technology is estimated to see demand in conjunction with the industry-wide preparation for the upcoming BS VI emission and real-world fuel economy norms in India.

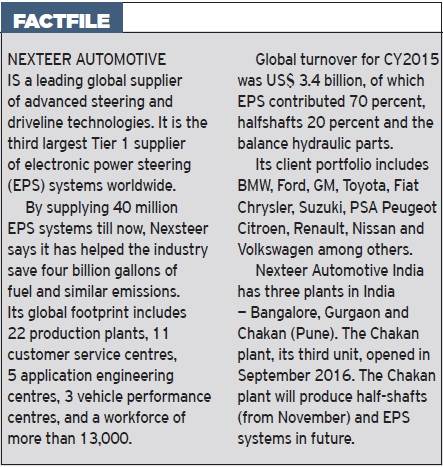

While a steering system consists of the components required to provide lateral directional control of the vehicle, the driveline system comprises of parts required to transfer power from the transmission to the drive wheels. Nexteer’s steering system product lines include electric power steering, hydraulic power steering as well as steering columns and intermediate shafts. Under its driveline system product portfolio, it supplies front-wheel drive half-shafts, intermediate drive shafts and rear-wheel drive half-shafts as well as propeller shaft joints.

In an exclusive interaction with Autocar Professional, Madhav Kulkarni, managing director, Nexteer Automotive India, says: “The most popular product that we develop, manufacture and supply is the half-shaft, which contributes to almost 70-75 percent of business in India. The rest comes from columns and hydraulic steering assemblies. We are not supplying EPS systems in India currently. However, it is our wish to start manufacturing and supplying these advanced steering systems in India. Our global team has committed that we will be venturing into this product category soon. We have even reserved around 50 percent of the area in our new Chakan plant for the future production of the EPS systems.”

“With new emission norms coming in and the improving infrastructure countrywide, the focus is now on quieter vehicles, thereby reducing noise and vibrations in driving. New trends including NVH and lightweighting efforts are gaining ground. From the half-shaft side, it is seeing downsizing or optimum sizing for vehicle-specific applications. We estimate that we will see 100 percent transition from hydraulic power steering systems to embracing EPS systems,” he adds.

According to the top boss, Nexteer Automotive has had a presence in India for the last 21 years. “We started in 1995 when we were supplying half-shafts to the Maruti 800,” Kulkarni recalls.

Nexteer has subsequently expanded its customer base in India, which now also includes Tata Motors, Mahindra & Mahindra, Renault-Nissan and others. Kulkarni estimates that the India business will touch a turnover of US$ 52 million or roughly Rs 350-355 crore in the ongoing financial year. Interestingly, exports account for almost 40 percent of Nexteer’s India business.

“We have a robust export order book, which accounts for almost 40 percent of our India business. We are currently exporting made-in-India products to Suzuki Motor Corporation in Japan and General Motors in the USA,” reveals Kulkarni.

Recovering markets

It is a known fact that, over the past couple of years and a slugglish domestic market, automakers in India along with their suppliers invested in building their R&D capabilities and innovative solutions. New models like the Maruti Baleno, Maruti Vitara Brezza, Renault Kwid, Tata Tiago and others, on which the OEMs were working when the markets were stagnant, are clearly the volume drivers of domestic demand today.

Talking in this regard, Kulkarni underlined, “Only Maruti Suzuki was the remaining OEMs were declining over the past few years. This year, however, I see that there is good market growth. I anticipate that the car market will grow at least 8-10 percent in FY2017. The overall growth is now not only coming from the market leader but also from Renault-Nissan, which is increasingly becoming a major player, all thanks to the Kwid models.”

Notably, Nexteer is associated with the high-volume models from the Maruti Suzuki stable as well as Renault-Nissan. “We have almost 50 percent share of the Maruti Suzuki Alto business and we are the single-source supplier for the both 800cc and 1-litre engine models of the Renault Kwid,” discloses Kulkarni, who also estimates that the company’s business will grow to the tune of 22 percent during FY2017.

“This year we will be growing at 22 percent YoY. Whatever efforts we had put in during the past few years, specifically in 2014-15, are now paying returns. I am very confident that we will be able to maintain a CAGR of 15 percent from the ongoing financial year onwards for the upcoming 4-5 years on the back of our strong order book,” he adds.

Renault-Nissan and new customers on board for Nexteer will continue to play a crucial role in its strong order book. According to Kulkarni, the company is also signed up for supplying specific part(s) for the Renault Kwid for its assembly operations in Brazil as well.

“Additionally, with Nissan we are going to launch a program which will see manufacturing in Europe. We will, hopefully, be supplying the half-shafts from India for that program,” he states.

The company also operates a customer application centre located in Bangalore, which facilitates interaction between customers and engineering centres in China and the USA.

Manufacturing footprint

Nexteer Automotive currently has three production units in India, with the latest and third manufacturing facility inaugurated in September 2016. While the mother plant is located in Bangalore (originally set up by Delphi as its first plant in India in 1996), the company also has a dedicated unit in Gurgaon to cater to Maruti Suzuki. “The Gurgaon plant exclusively caters to the business from Maruti Suzuki on a just-in-time (JIT) basis,” says Kulkarni.

The Chakan plant, which entailed investments of more than US$ 2 million (Rs 12.63 crore), is aimed at growing the existing business with the OEMs located in the region. The plant, whose shopfloor is currently spread across 35,000 square feet, can take on future capacity expansion (for EPS assembly operations) with an additional 35,000 square feet.

The company is already discussing the prospects of supplying EPS systems with OEMs in India. “If it is required, we can start with end assembly operations at the Chakan unit and work on backward integration, given that EPS orders come sooner than expected,” remarks Kulkarni.

The new plant, which is also the 22nd production unit for Nexteer Automotive globally, will start manufacturing half-shafts and assembly in November 2016. The unit is slated to provide employment to nearly 120 skilled workers.

Tao Liu, global vice-president and Asia Pacific chief operating officer of Nexteer Automotive, who was present at the Chakan plant's inauguration ceremony, had said, “The opening of our facility in Pune and our expanded production capacity in India are important pieces in our long-term development strategy in India. With this strategic addition, we are able to better serve customers in both the domestic and international markets.”

By making moves to be future-ready in its Indian operations, Nexteer Automotive is ensuring it can handle a flood of orders when OEMs in India take to electronic power steering in a bigger way.

This article was first published in Autocar Professional's October 15, 2016, issue.

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

By Amit Panday

By Amit Panday

29 Oct 2016

29 Oct 2016

29808 Views

29808 Views