Ferrari, Ford, Fiat, GM use made-in-Gujarat castings

Tamboli Castings manufactures investment castings and supplies to some of the most quality-driven companies in various industries including automotive, construction, mining, forming and fabricating, petrochemical, material handling, hydraulic equipment, pumps and valves, and power transmission.

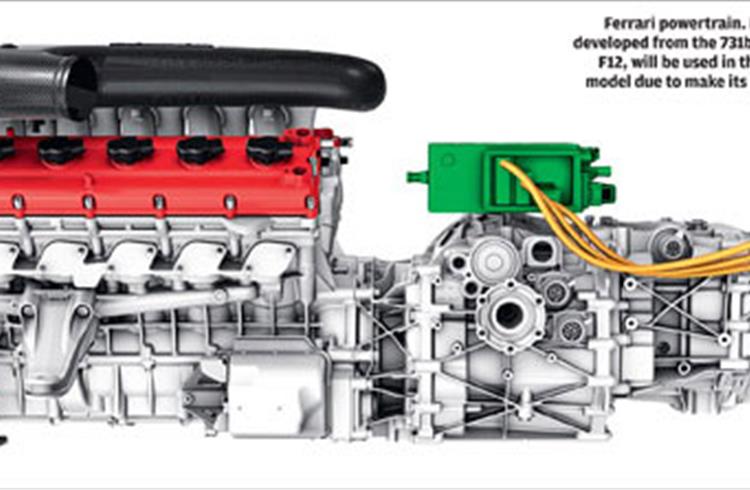

As big as it gets, Tamboli Castings is the Tier 2 supplier of crucial powertrain parts which are used in the gasoline direct injection system to Ferrari SpA, General Motors, Ford Motor Company, and Fiat SpA. The aforementioned components are supplied via the largest automotive component supplier in the world, Robert Bosch GmbH. According to a company official, TCL supplies components which go into the V12 engines of Ferrari (currently deployed in two officially available models – the F12 Berlinetta, which is claimed to be the most powerful road-legal Ferrari ever built, and the Ferrari FF, which is claimed to be the fastest four-seater in the world), Alfa Romeo and Lancia cars from the Fiat Group, and Ford Motor Co's Mondeo and Galaxy models.

In order to maintain the secrecy of client-specific agreements, the company did not reveal the details of the contracts. Furthermore until recently, TCL was also the Tier 2 supplier to the Tata Motors-owned British marque Jaguar Land Rover. However, for undisclosed reasons, the company is not currently supplying to JLR.

Tamboli Castings manufactures investment castings and supplies to some of the most quality-driven companies in various industries including automotive, construction, mining, forming and fabricating, petrochemical, material handling, hydraulic equipment, pumps and valves, and power transmission. The automotive domain, however, stands as the largest contributor in terms of operations and has a majority share of between 50-60 percent of the company’s total revenues.

According to Mehul Tamboli, director, Tamboli Castings, “Bosch is our biggest client in terms of the revenues in the automotive vertical. We initially started supplying our components to Ferrari, JLR, Ford, GM and Fiat in 2009 via Bosch. The despatches are made every month,” he reveals.

Recognised as one of the most modern investment castings company with a high degree of automation, TCL’s product portfolio includes stainless steel castings for EGR (exhaust gas recirculation, used as one of the emission reduction techniques) coolers, EGR cooler valves, transmission and powertrain aggregates including injection nozzle clamps and rocker arms.

|

The company manufactures nearly 150 different types of automotive components. Tamboli estimates that the annual global market size of the automotive components, specifically the investment castings and some other aggregates the company manufactures, stands at US$ 1.7-2.5 billion (Rs 9,254-13,610 crore).

Quality speaks

“Our stringent quality standards and precision- based work are well appreciated. We work rigorously as per the customer’s requirements, leaving no scope for faults. A right mix of ultra-efficient machines and highly trained workforce ensures that the given measurements are tightly followed without leaving any gap of even a single micron. One micron is a one-thousandth part of one millimetre,” explains Tamboli.

The company has installed around 30 sophisticated CNC machines, imported primarily from Germany and Japan, along with other support equipment such as the coordinate measuring machines and others. TCL machines out nearly 500,000 units of the castings every year.

The company has invested around Rs 35 crore in the last five years. Of this, Rs 17 crore has been spent during the last two years, directed majorly on installing the machines, and upgrading and expanding the plant at Bhavnagar. The listed company is also planning substantial capacity expansion in the near future. Though the company official did not disclose the details of the planned capacity expansion, he did confirm that the company will be investing in excess of Rs 10 crore in the coming years on capex. “In our business, we work almost two to three years in advance. The gestation period is very long as several design changes are proposed by the OEMs and component makers before the product is finally approved and put into mass production. We are currently working on our projects which will kick-start in 2014 and 2015,” adds Tamboli.

|

He sees the US-based Hitchiner Manufacturing Co, Inc, which is one of the largest suppliers of investment castings to auto giants like BMW, Daimler, Volkswagen, General Motors and others, as one of the toughest competitors on the global front. On the other hand, he reasons out a potential threat from Chinese automotive component manufacturers as well. “As we know, the global recession of 2008-2010 pushed many global auto OEMs and Tier 1 and Tier 2 auto component suppliers out of business. It was then that many Chinese firms had stepped up and acquired European and American technologies and companies. This is one of the major reasons why China manufactures some of the world’s best-quality products today,” said Tamboli.

Going forward

Tamboli believes that technological innovations in the areas around lowering emission and boosting fuel efficiency would drive growth and stand as a lucrative opportunity. He also anticipates growth in the areas around petrol direct injection technology and its application in growing economies like India. “We are under constant pressure in areas like reducing prices, upgrading quality, and providing value-added services to our customers. For increased productivity and efficiency, we are practicing lean manufacturing in some areas at our plant. We are also focussing on providing more value- added services such as machining the raw castings, performing the heat treatment and other necessary processes as per customer’s customisation and ensuring just-in-time (JIT) deliveries,” he says.

|

Usually, it is the Tier 2 component suppliers which provide raw products and lack the capability of providing value-added services. TCL, being both a Tier 1 and Tier 2 supplier, is capable of further machining the raw castings, performing the induction hardening, electroplating, electro- polishing, hard chrome plating, pressure testing and other required processes for its customers, ensuring that the final shipment is in a ready-to-use condition.

Indian growth story

Indian companies which are 100 percent export-oriented units like Tamboli Castings are affected the most when the developed economies of Europe, US and Japan are hit by recession. As a result, the stagnating consumption leads to a drop in the demand for auto components.

In the wake of such times, Asian economies (China, India and Thailand)have caught the attention of global automotive players who are increasingly setting up their footprints in this region to not only grab a share in the robust demand locally, but to also support their global businesses.

The company official sees India as a highly lucrative market and is working to tap the potential of the domestic market with more focus.

Sitting at an advantageous location of Gujarat, the company is currently busy chalking out an exclusive India plan to address the demand at home. From a turnover of Rs 17.74 crore in 2009-10, the company had posted progressive turnovers of Rs 36.30 crore and Rs 53.70 crore for 2010-11 and 2011-12 respectively.

All said and done, companies such as Tamboli Castings are a prime example of the new global India which isn’t just a country where small is big (for passenger cars and two-wheelers), but is also home to some of the best quality manufacturing practices followed by the Tier 1 and Tier 2 component makers who can ably suit the stringent requirements of some top-notch global automakers.

AMIT PANDAY

RELATED ARTICLES

BRANDED CONTENT: Serving India’s EV ecosystem

Shimnit Integrated Solutions Pvt. Ltd. (SISPL), a subsidiary of Mumbai's leading high-security number plate supplier, Sh...

Driving EV business with agility and flexibility

CEOs from the EV startup ecosystem met in Bengaluru and Pune to discuss the challenges and business opportunities.

BRANDED CONTENT: SM Auto and Gotech energy inaugurate their first battery pack assembly plant in Pune

Pune-based SM Auto Engineering (SMA), a leading automotive component system manufacturer and its partner Gotech Energy (...

By Autocar Pro News Desk

By Autocar Pro News Desk

03 Jan 2013

03 Jan 2013

12004 Views

12004 Views