Audi México: state-of-the-art technology for top quality

To validate its premium quality, the company is networking its new plant with other sites in the Audi global production network.

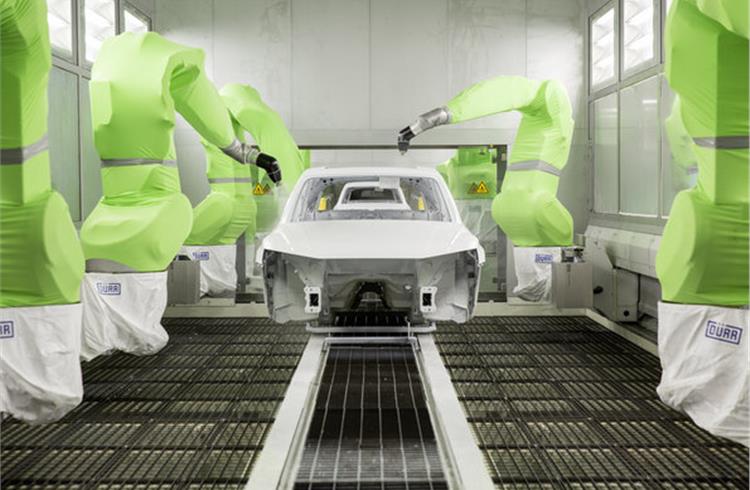

October 1 saw the official opening of the Audi Mexico plant in San José Chiapa. The guiding principle here is ‘made by Audi’: The Audi Production System (APS) implements a uniformly high standard for quality worldwide.

To validate its premium quality, the company is networking its new plant with other sites in the Audi global production network. Working in the production control center, known as P-Control, are 105 employees from various technical disciplines, who monitor how the new Audi Q5 is produced from a bird's-eye view. In combination with the site’s quality laboratory and training center, Audi ensures compliance with the quality standards that apply to its production facilities worldwide.

The Audi production control room in San José Chiapa is the first that combines five control consoles.

Over a floor area of 400 square metres, employees of the P-Control centre monitor the production of the new Audi Q5 in three shifts. For the first time, this central control station combines five control consoles, which are often in separate places at other Audi production sites – at the logistics and maintenance control consoles, for instance.

“The centralised P-control station is the most advanced in the Audi production network, symbolizing the Audi Smart Factory,” says Prof. Dr. Hubert Waltl, Board Member for Production at Audi AG. “The combined layout of individual interfaces enables effective, direct communication between the different control centres. This enables us to detect the slightest of deviations early on, and we are able to react quickly.”

Another example of how the premium manufacturer is driving digitalisation and networking at its plants was said to be based in its cooperation among production sites. Audi staffers in Ingolstadt, Germany can even gain access to the control centre of Audi México to offer technical support.

At the plant's dedicated quality laboratory, employees in Mexico ensure that globally applicable quality standards are met for the new Audi Q5. “All parts undergo a broad array of tests at the laboratory in San José Chiapa. This lets us fulfill premium Audi standards worldwide,” says Alfons Dintner, CEO of Audi México. Employees use state-of-the-art equipment to test whether the metallic or nonmetallic materials conform to the desired properties. In the light studio, quality assurance experts examine interior parts for the new Audi Q5 under different lighting conditions, in a process known as ‘colour matching’. Their objective is to ensure colour appears perfectly consistent in different materials. Audi México also has three master jigs. This is where individual car parts are fine-tuned using state-of-the-art tactile and optical measuring equipment.

At the Audi Training Center, employees obtain the crucial qualifications for their job activities in the P-Control center and quality laboratory. The 20,000 square metre building for education and training is located right at the plant in San José Chiapa. All Audi México employees undergo specialised training here that is precisely tailored to their later work in the plant. The training centre features the same highly advanced equipment that is used at the plant. “In cooperation with the Universidad Tecnológica de Puebla, we have created a facility where we can qualify our Mexican employees to the global Audi qualification level. This is how we are optimally preparing Audi México for the challenges of the future,” says Prof. Thomas Sigi, Board Member for Human Resources. Audi México currently has a local workforce of around 3,300 employees. This figure is expected to grow to a total of around 4,200.

Also read: Audi México opens Just-In-Sequence supplier park in San José Chiapa

RELATED ARTICLES

BRANDED CONTENT: Eliminating the worries of battery charging with smart solutions

The charging infrastructure is the backbone of electric mobility but is also one of the key perceived barriers to EV ado...

The battery-powered disruptor

Greenfuel Energy Solutions is planning to shake up the EV battery market with the launch of a portfolio of specially eng...

SPR Engenious drives diversification at Shriram Pistons & Rings

The engine component maker is now expanding its business with the manufacturing of motors and controllers through its wh...

By Autocar Pro News Desk

By Autocar Pro News Desk

03 Oct 2016

03 Oct 2016

8934 Views

8934 Views